Novel corrosion-resistant cement and application thereof

A corrosion-resistant, new type of technology, applied in the field of corrosion-resistant cement, can solve problems such as low work efficiency and waste of discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

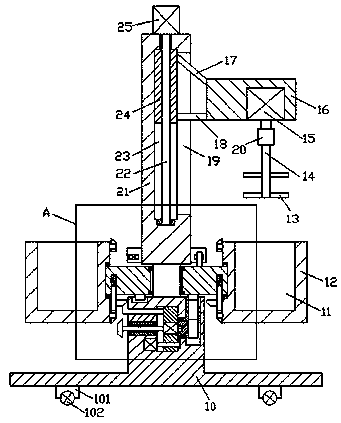

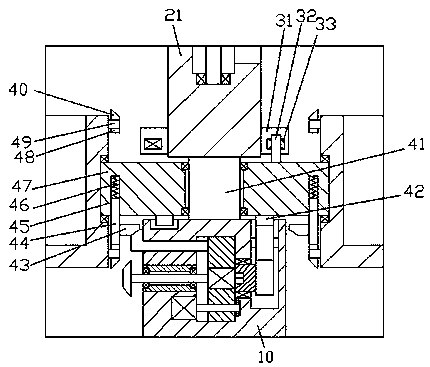

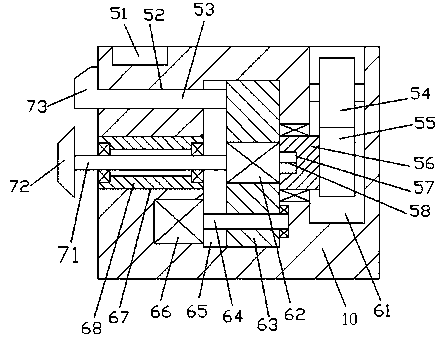

[0014] Combine below Figure 1-4 The present invention will be described in detail.

[0015] refer to Figure 1-4 , a new type of corrosion-resistant cement and its application according to an embodiment of the present invention includes a bottom plate 10, a first rotating pin shaft 41 is fixed at the center of the upper end of the bottom plate 10, and the upper end of the first rotating pin shaft 41 is fixed A support 21 is provided, and an agitating member is installed on the support 21 for lifting adjustment. The outer periphery of the first rotating pin shaft 41 is rotated and installed with a tightening plate 47, and the end faces of the left and right sides of the tightening plate 47 are symmetrically fixed. There is a storage barrel 12, the top end surface of the storage barrel 12 is provided with a storage cavity 11, and the opposite side end surfaces of the storage barrel 12 on the left and right sides are fixed with a circular ring 49, and the outer circumference of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com