Palladium-loaded ferrocene-based ultrathin metal organic frame nanometer sheet and preparation method thereof

An ultra-thin metal-organic framework technology, applied in the field of material chemistry, can solve the problems of destroying the structure of metal-organic framework nanosheets, harsh reduction conditions, and inability to ensure the loading of metal nanoparticles, and achieve superior catalytic performance and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In a 500mL round-bottom flask, add ultra-thin metal-organic framework nanosheets (5mg) and water (250mL), and disperse them by ultrasonication for 30min to obtain an ultra-thin metal-organic framework nanosheet dispersion. Potassium chloropalladate (1.63 mg, 0.1 mmol) was added to the dispersion, and reacted at 30°C for 5 hours. After the reaction, centrifuge (3000rpm, 30min) to obtain a precipitate. The resulting precipitate was re-dispersed ultrasonically with water (30 mL), and centrifuged again to obtain the precipitate. After repeating the above ultrasonic dispersion and centrifugation operations three times, the palladium-loaded ultrathin metal organic framework nanosheets were obtained.

Embodiment 2

[0037] In a 500mL round-bottom flask, add ultra-thin metal-organic framework nanosheets (100mg) and water (250mL), and disperse them by ultrasonication for 30min to obtain an ultra-thin metal-organic framework nanosheet dispersion. Potassium chloropalladate (32.6 mg, 0.1 mmol) was added to the dispersion, and reacted at 30°C for 5 hours. After the reaction, centrifuge (3000rpm, 30min) to obtain a precipitate. The resulting precipitate was re-dispersed ultrasonically with water (30 mL), and centrifuged again to obtain the precipitate. After repeating the above ultrasonic dispersion and centrifugation operations three times, the palladium-loaded ultrathin metal organic framework nanosheets were obtained.

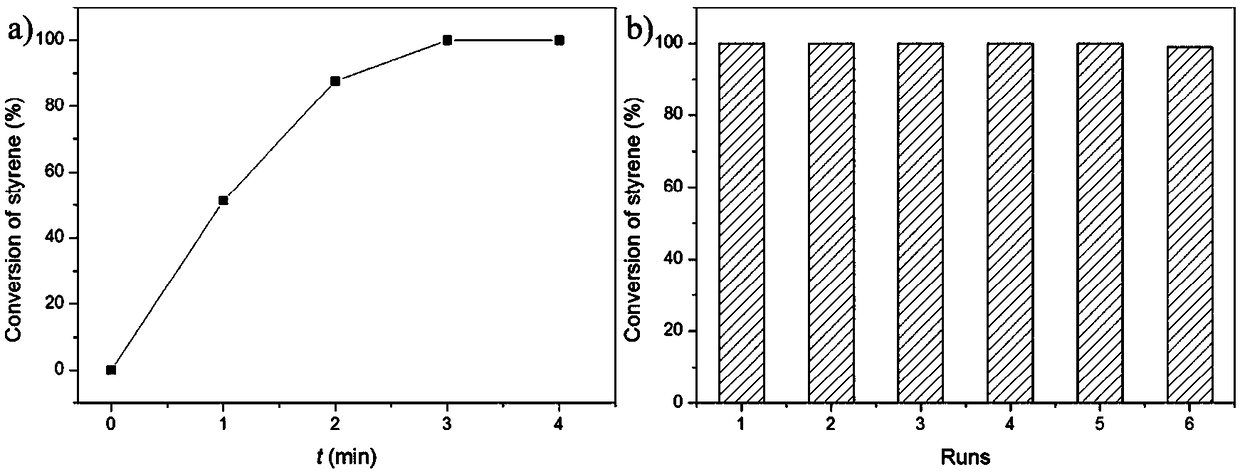

[0038] The experimental test results are as follows:

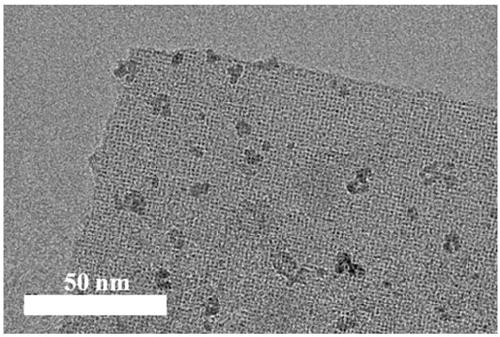

[0039] Such as figure 1 Shown is the transmission electron microscope image of the prepared palladium-loaded ultra-thin metal-organic framework nanosheets. It can be seen from the figure that the palladium particles are...

Embodiment 3

[0042] In a 500mL round-bottom flask, add ultra-thin metal-organic framework nanosheets (500mg) and water (250mL), and disperse them by ultrasonication for 30min to obtain an ultra-thin metal-organic framework nanosheet dispersion. Potassium chloropalladate (326 mg, 1 mmol) was added to the dispersion, and reacted at 30°C for 5 hours. After the reaction, centrifuge (3000rpm, 30min) to obtain a precipitate. The resulting precipitate was re-dispersed ultrasonically with water (30 mL), and centrifuged again to obtain the precipitate. After repeating the above ultrasonic dispersion and centrifugation operations three times, the palladium-loaded ultrathin metal organic framework nanosheets were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com