Automatic adjusting and control method for pH of slurry of absorption tower

A control method and automatic adjustment technology, applied in the direction of non-electric variable control, multiple fluid ratio control, separation method, etc., can solve the problems of easy blockage of slurry supply pipeline, large delay, etc., to prevent blockage and improve desulfurization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

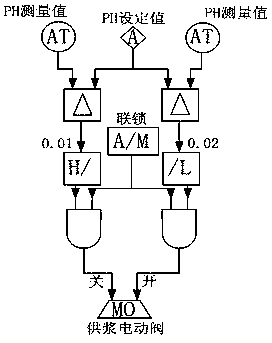

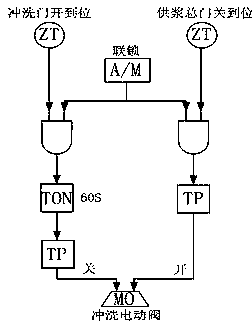

[0012] The present invention will be clearly and completely described below in conjunction with the accompanying drawings, so that those skilled in the art can fully implement the present invention without creative work.

[0013] The specific embodiment of the present invention is: as Figure 1-2 Shown are the schematic diagram of the control principle diagram of the electric valve for slurry supply and the schematic diagram of the control principle diagram of the flushing electric valve of the present invention, a method for automatic adjustment and control of the pH of the slurry in the absorption tower, the method includes: setting the target value of the pH value; pH value: According to the deviation between the detected pH value and the set pH target value, the action of the electric valve of the slurry supply switch is interlocked, so that the pH value is controlled at the pH target value.

[0014] Further, the closed-loop intermittent control method of the slurry supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com