Continuous film punching device for rapeseed perforating film laying hole seeder

A technology of punching device and hole seeding machine, which is applied in application, excavation/covering of trenches, agriculture, etc., can solve the problems of inapplicability to small-grained rape crops, immature punching technology, and easy tearing of agricultural films, etc. Easy to pierce the mulch, high punching efficiency and good punching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

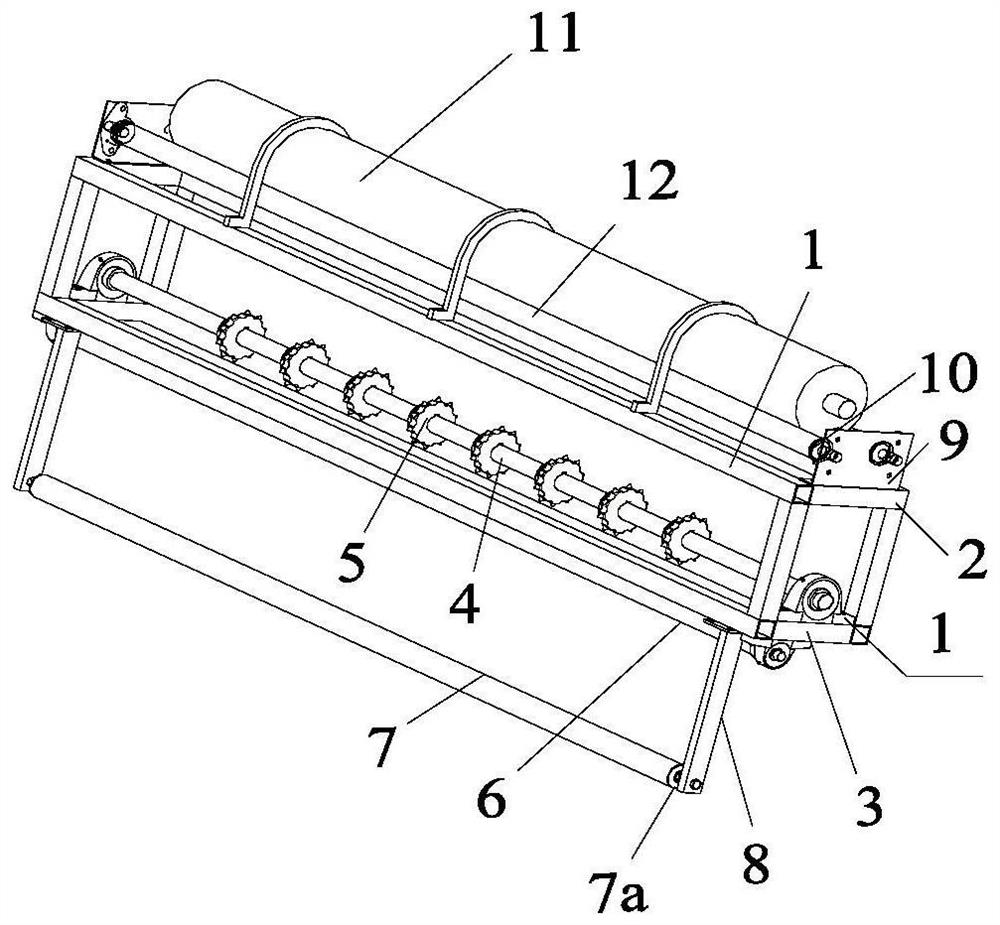

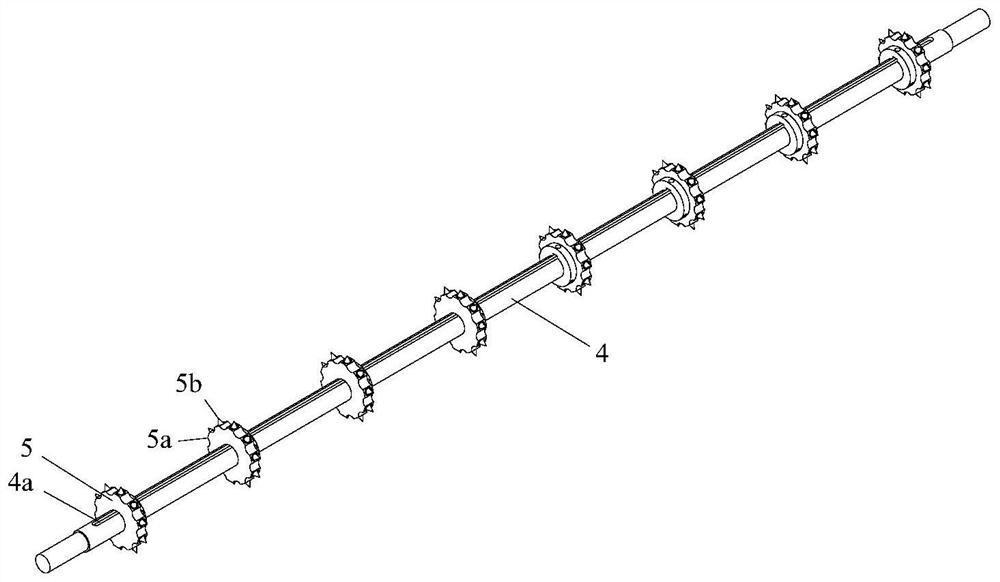

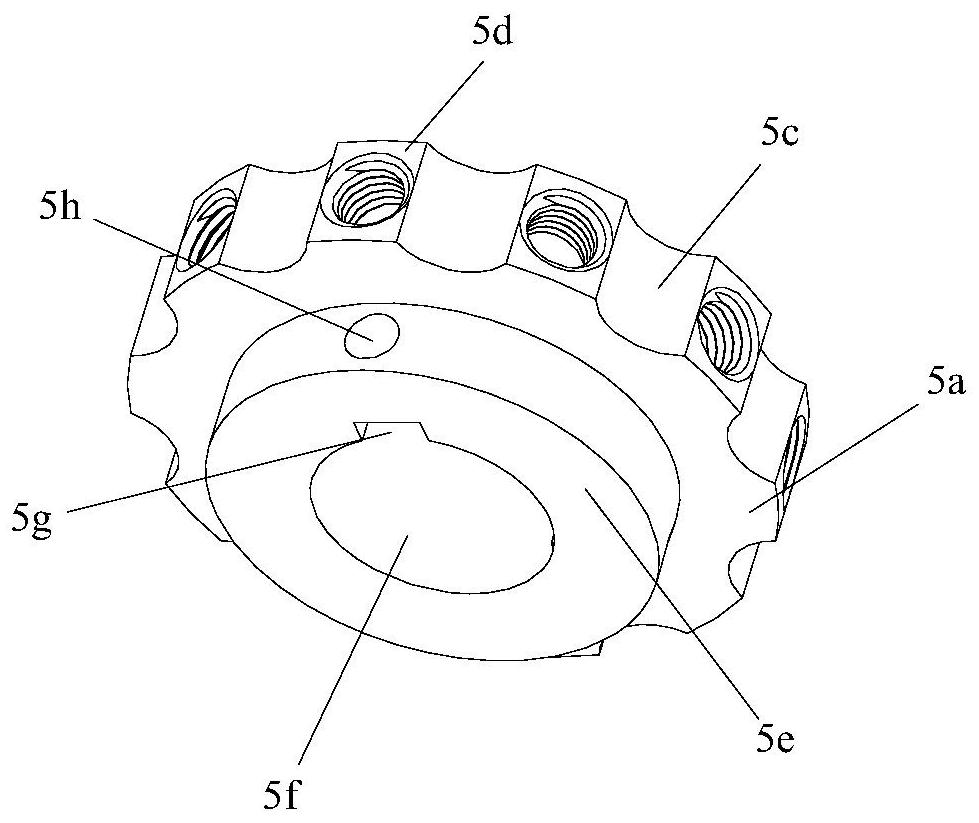

[0051] Such as figure 1 The shown continuous film punching device for rapeseed perforating film laying machine includes a fixed frame 1, a rotating drum device installed on the two upper side beams 2 of the fixed frame 1, and installed on the two lower side beams 3 of the fixed frame 1 The main shaft 4 on the surface, a plurality of punching units 5 that are sleeved on the main shaft 4 and arranged along the axial direction of the main shaft 4, the enlarged wrapping angle rollers 6 installed on the lower surface of the two lower side beams 3 of the fixed frame 1 and installed on the fixed The film spreading roller 7 on the bottom surface of the frame 1 and located obliquely below the wrapping angle increasing roller 6 . Wherein, one end of the spreading roller 7 is hinged to one end of the connecting rod 8 on one side through the tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com