A Method of Ultrasonic Imaging Based on Phase Ring Statistical Vector

An ultrasonic imaging method and ring-shaped technology, applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measurement devices, can solve signal amplitude interference, ultrasonic image signal-to-noise ratio and resolution It is difficult to meet the requirements of defect identification and other problems, and achieve the effect of high-precision quantification, good promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

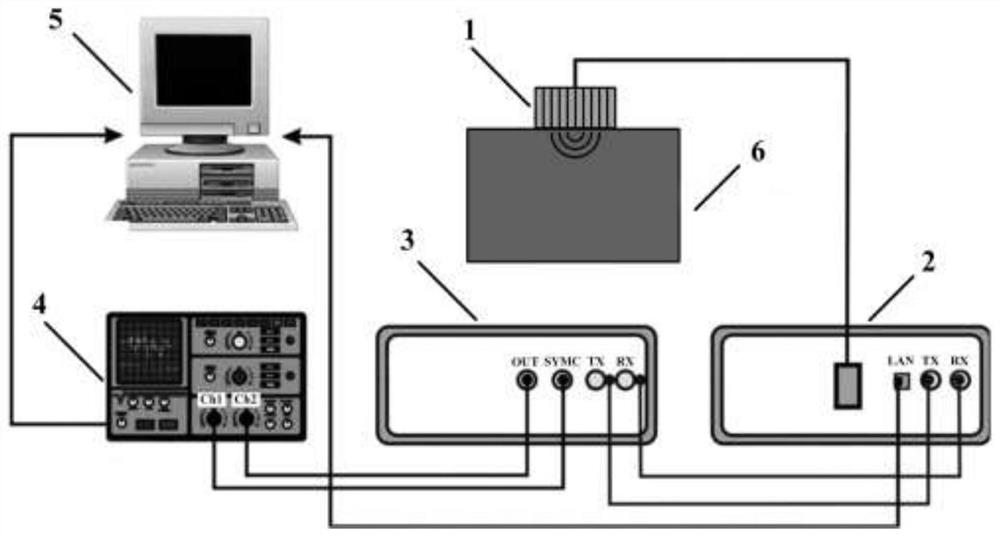

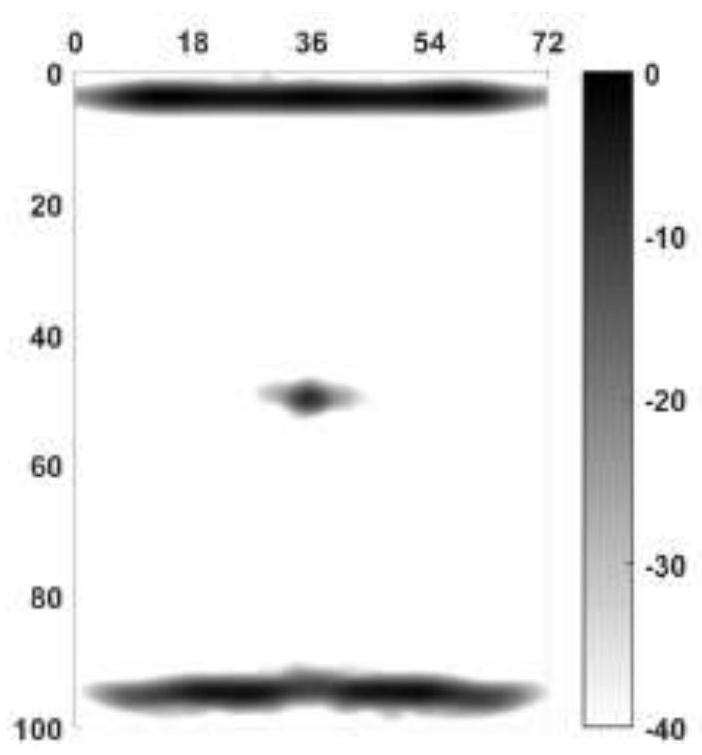

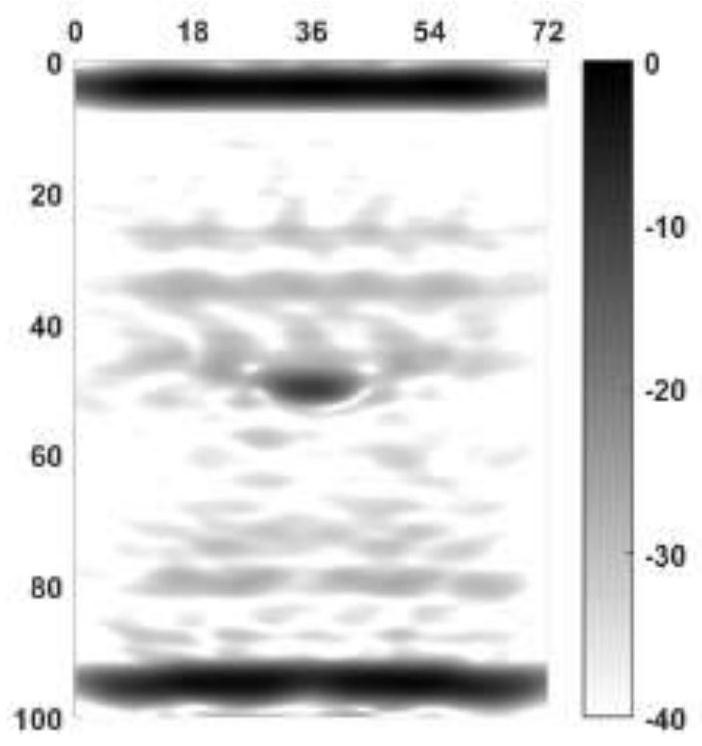

[0029] The present invention will be further described below in conjunction with drawings and embodiments. see Figure 1 to Figure 3 , an ultrasonic imaging method based on circular phase statistics vectors, taking the imaging detection of a 50mm deep Φ3 side drill hole in a 96mm thick coarse-grained austenitic stainless steel test block as an example, including the following steps:

[0030] 1) if figure 1 As shown, an independent 128-channel ultrasonic signal acquisition system is built through a phased array probe 1, a multi-channel selector 2, an ultrasonic signal transmitter receiver 3, a digital oscilloscope 4, and a computer terminal 5. Among them, the phased array probe 1 is connected with the multi-channel selector 2, and the multi-channel selector 2 and the ultrasonic signal transmitter receiver 3 are connected through the transmitting interface TX and the receiving interface RX, and the connection between the multi-channel selector 2 and the computer terminal 5 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com