Interference reflection type optical film microscopic measurement method based on structured light

An optical thin film and microscopic measurement technology, applied in the field of optical imaging, can solve the problems of high detection cost, small scope of application, limited accurate determination, etc., and achieve the effects of improving imaging resolution, expanding spectrum range, and improving imaging contrast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

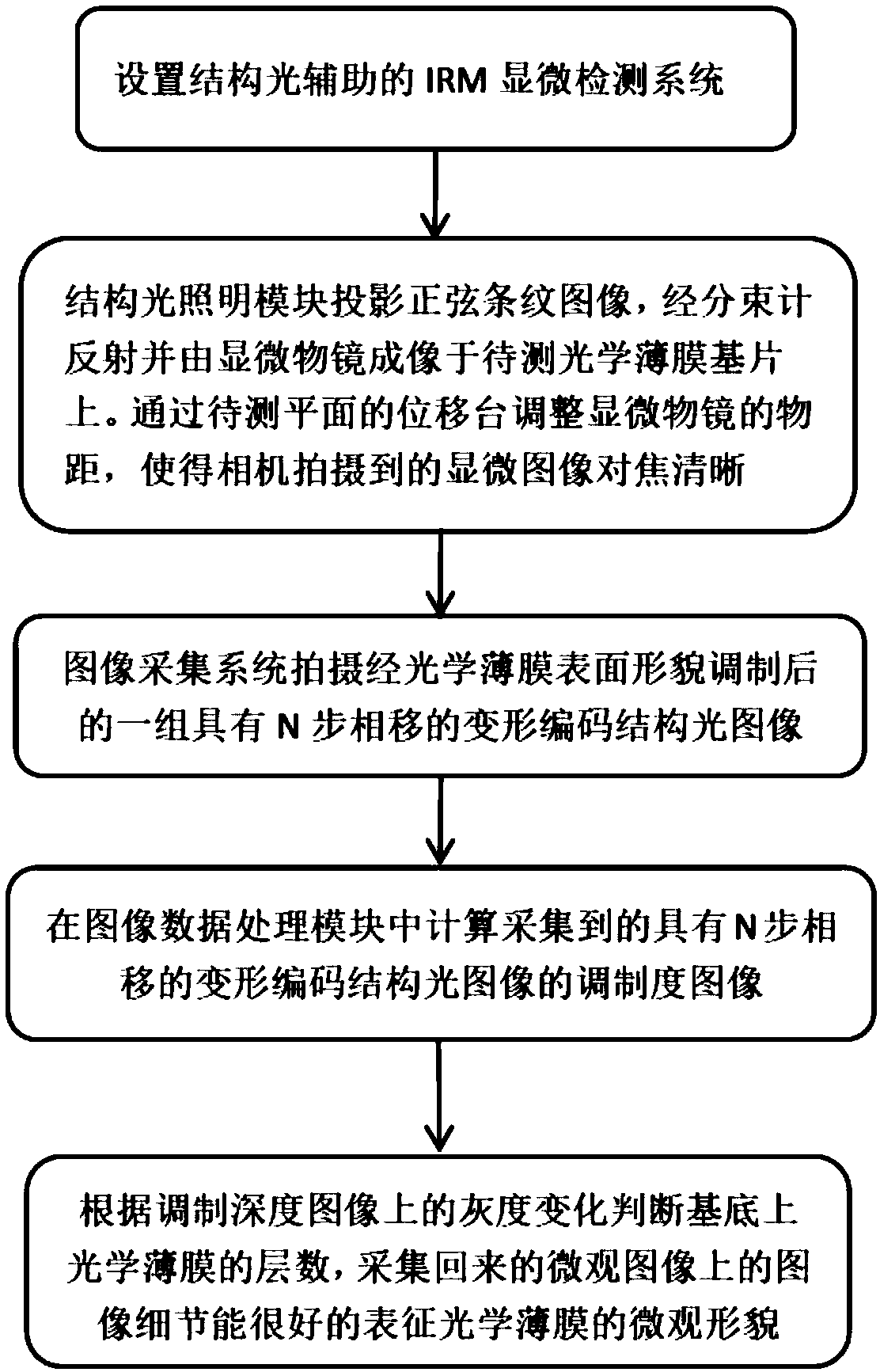

[0034] Embodiment 1: Encoded structured light with phase shift Take the standard N-step phase-shifted sinusoidal fringe light as an example, such as image 3 Shown is a schematic flow chart of detecting the surface morphology and the number of layers of an optical thin film using standard N-step phase-shifted sinusoidal fringe light. The specific method is:

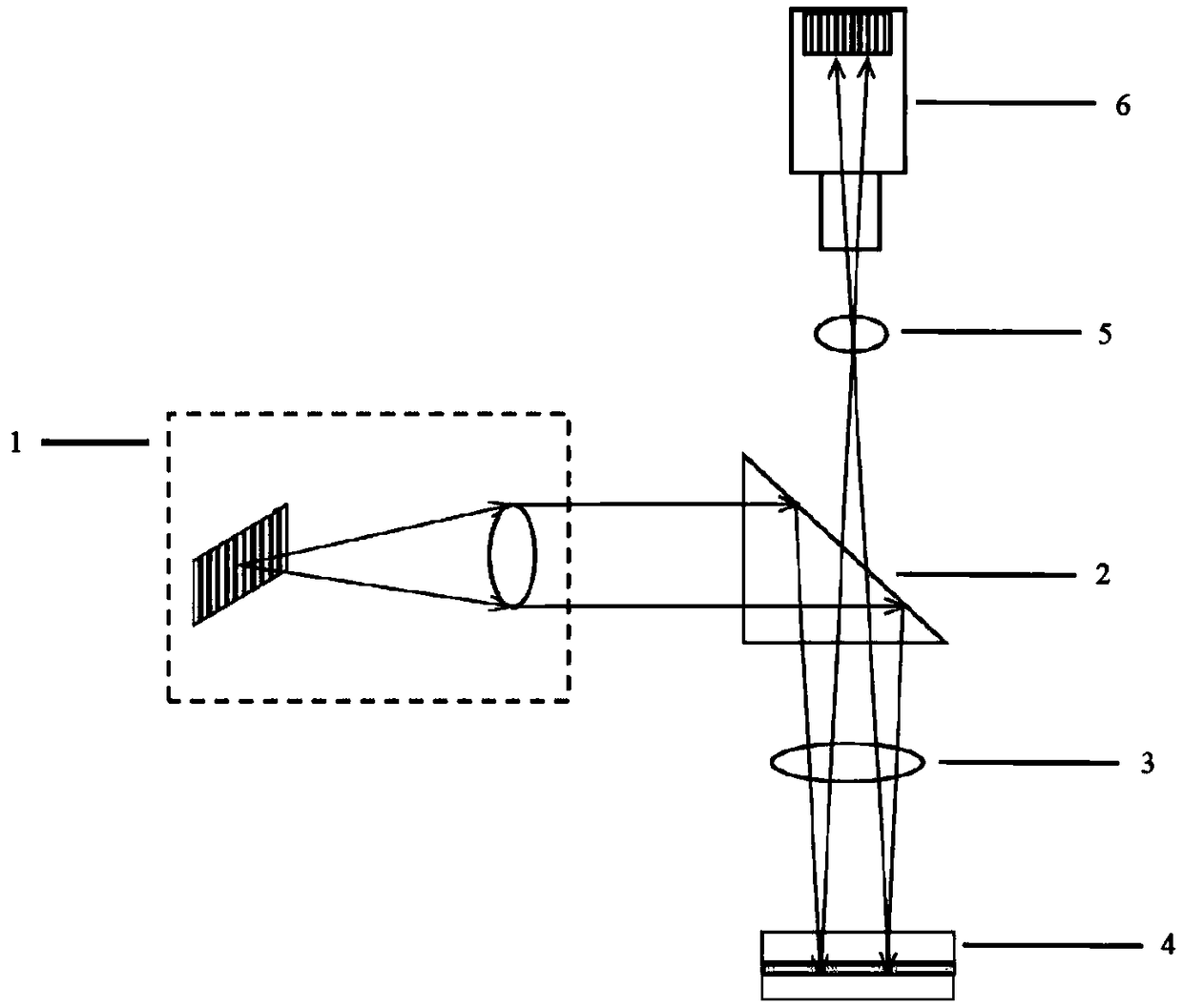

[0035] The structured light lighting module uses a 12.78mm×9mm high-brightness micro-OLED display. The structured light lighting module 1 also includes a collimation module connected to the collimated micro-display. Since the micro-OLED lighting needs to ensure the imaging effect, it uses The 35mm lens is collimated to ensure that the structured light lighting module 1 can produce converging structured light; the micro-OLED display changes the pattern of the projected striped structured light with the computer signal, and the micro-OLED display is controlled by the computer to change the pattern of different phases at a ce...

Embodiment 2

[0068] Embodiment 2: Encoded structured light without phase shift Taking the non-phase-shifted striped light as an example, the method of obtaining the surface morphology and the number of layers of an optical film by using the non-phase-shifted striped light is as follows:

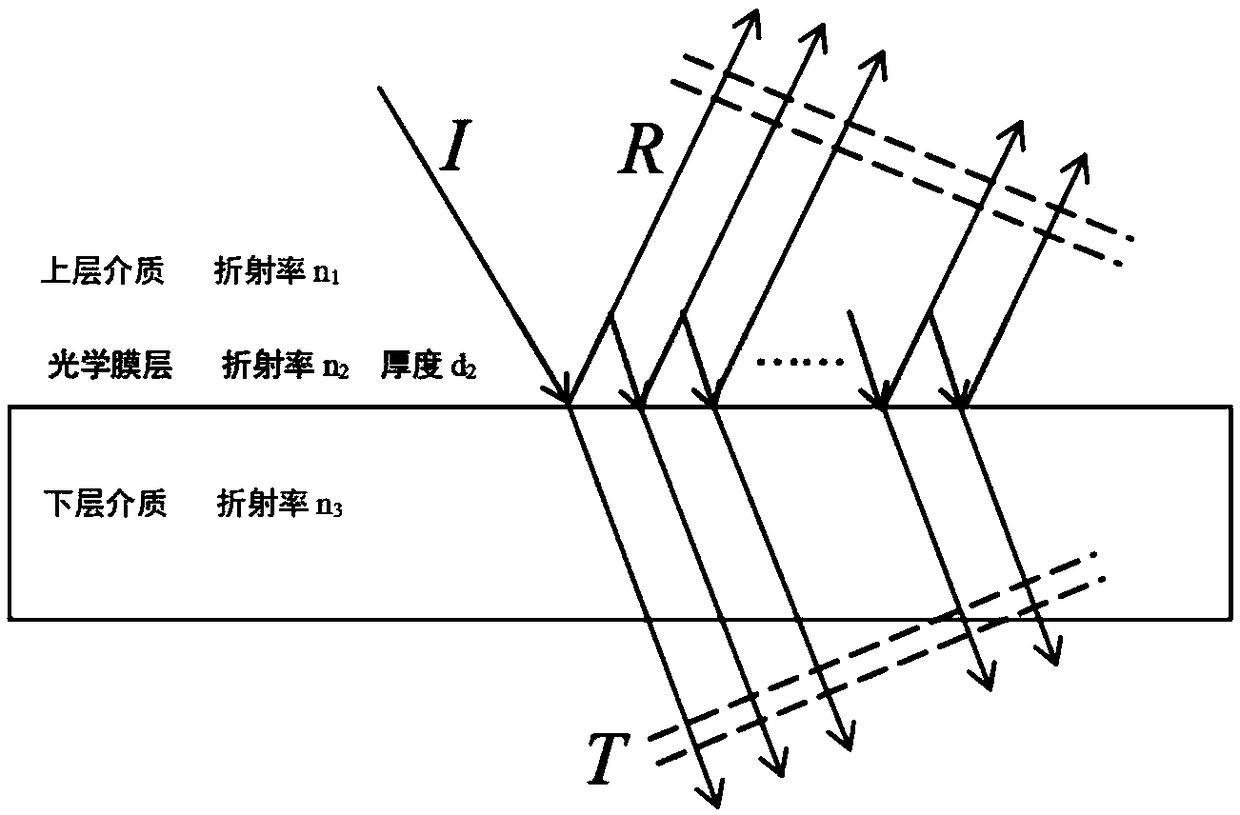

[0069] Also use the micro-OLED display to generate the striped structured light, but in this embodiment the micro-OLED display only projects one frame of sinusoidal striped images, and this image is collected in the image acquisition module 6 . A two-dimensional coordinate axis in the xy direction is established in the deformed interference pattern, and the light intensity information I(x, y) at the coordinate (x, y) in the deformed interference pattern contains phase information related to the height of the object and the surface reflectance Such as formula (10).

[0070]

[0071] In formula (10) is the real phase change caused by the height of the optical film and the surface reflectivity, f x an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com