Stable-pressure flat plate overflow valve

A technology of relief valve and flat plate, applied in the direction of balance valve, safety valve, valve device, etc., can solve the problem of stable supply of engine lubricating oil system pressure, achieve high functional integration, avoid sticking, and avoid the influence of system pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

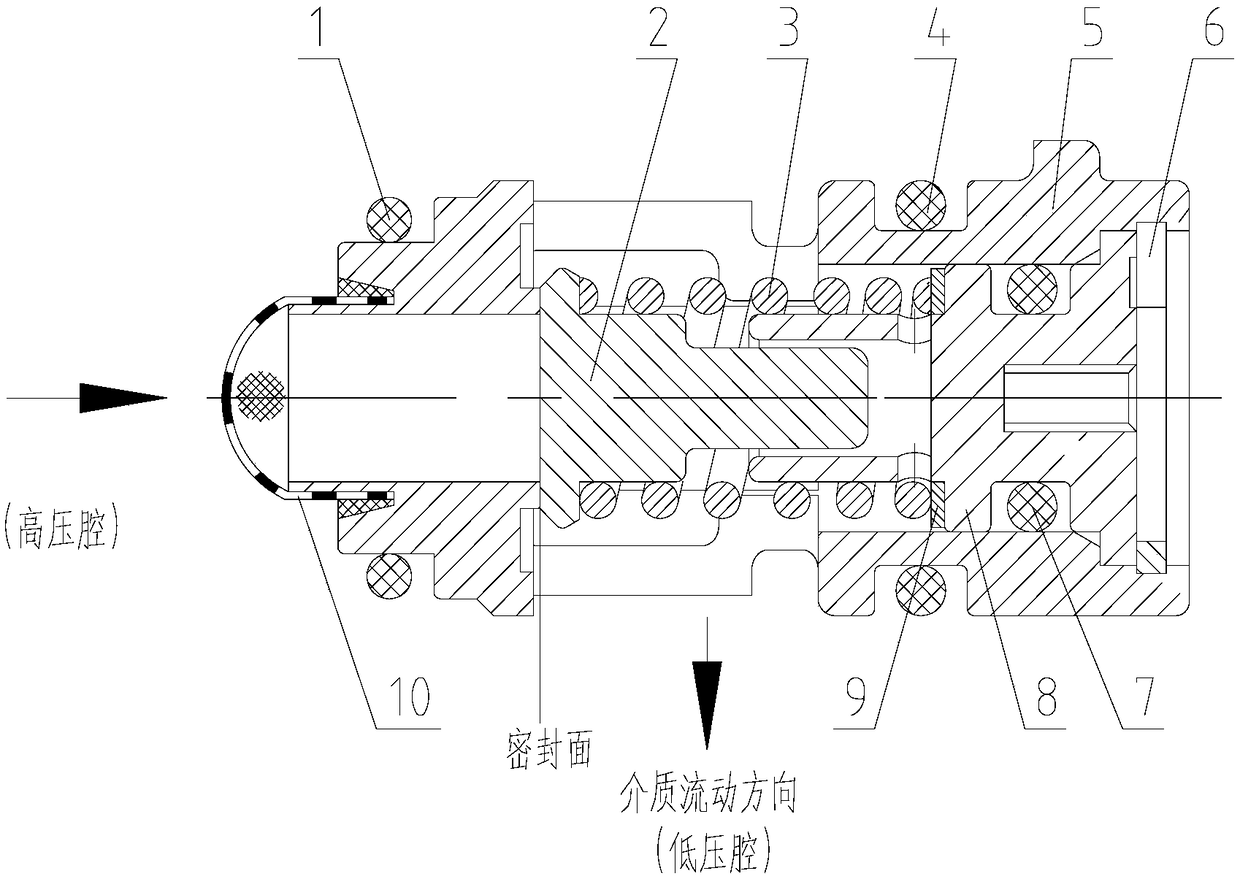

[0019] like figure 1 As shown, the present invention provides a pressure-stabilizing plate relief valve (hereinafter referred to as relief valve). The structure includes a sealing ring 1, a sealing cover 2, a spring 3, a sealing ring 4, a valve body 5, a retaining ring 6, a sealing ring 7, a spring seat 8, an adjusting gasket 9, and a filter screen 10.

[0020] The pressure-stabilizing plate relief valve as a whole is installed in the installation hole of the engine lubricating oil system in a plug-in manner. The system installation hole not only provides installation support for the relief valve, but also provides a medium flow path for the relief valve. The installation hole of the system includes a high-pressure ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com