Linear bearing with oil storage cabins

A technology of linear bearing and oil storage tank, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve problems such as bearing damage, and achieve the effect of preventing dry friction, increasing the effective time period of use, and rigid and firm clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

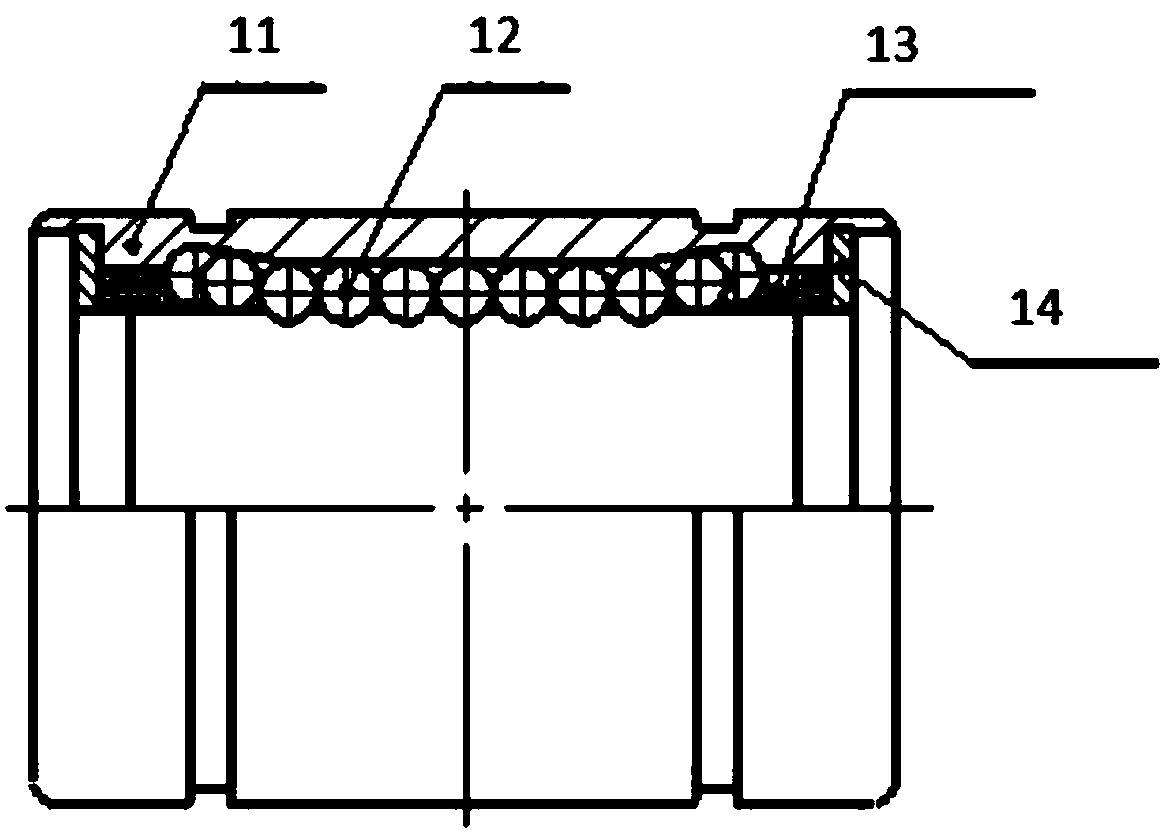

[0024] first see attached figure 1 , is a linear bearing in the prior art, including an outer ring 11, balls 12 and a cage 13 arranged inside, and sealing rings 14 are respectively arranged at both ends of the outer ring 11. When the upper shaft is matched, the ball 12 and the shaft The rolling friction between the sealing ring 14 and the shaft is sealed and slipped to prevent dust from entering the outer ring 11. Because there is no oil storage structure in this setting method, only a small amount of lubricating oil is immersed in the bearing, which will be consumed quickly during use. When the lubricating oil is lost, the bearing will be damaged soon.

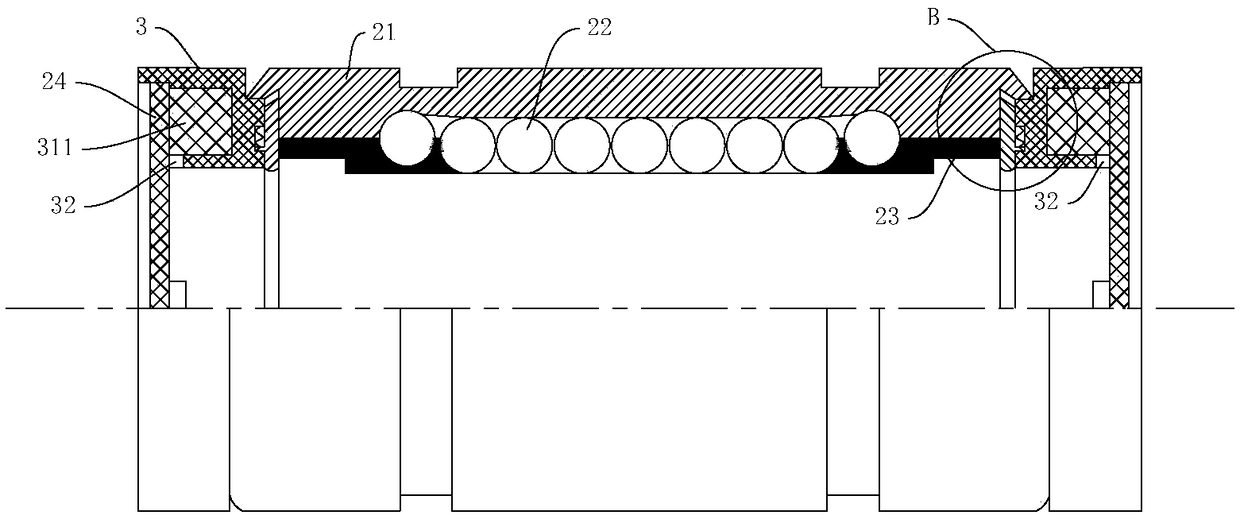

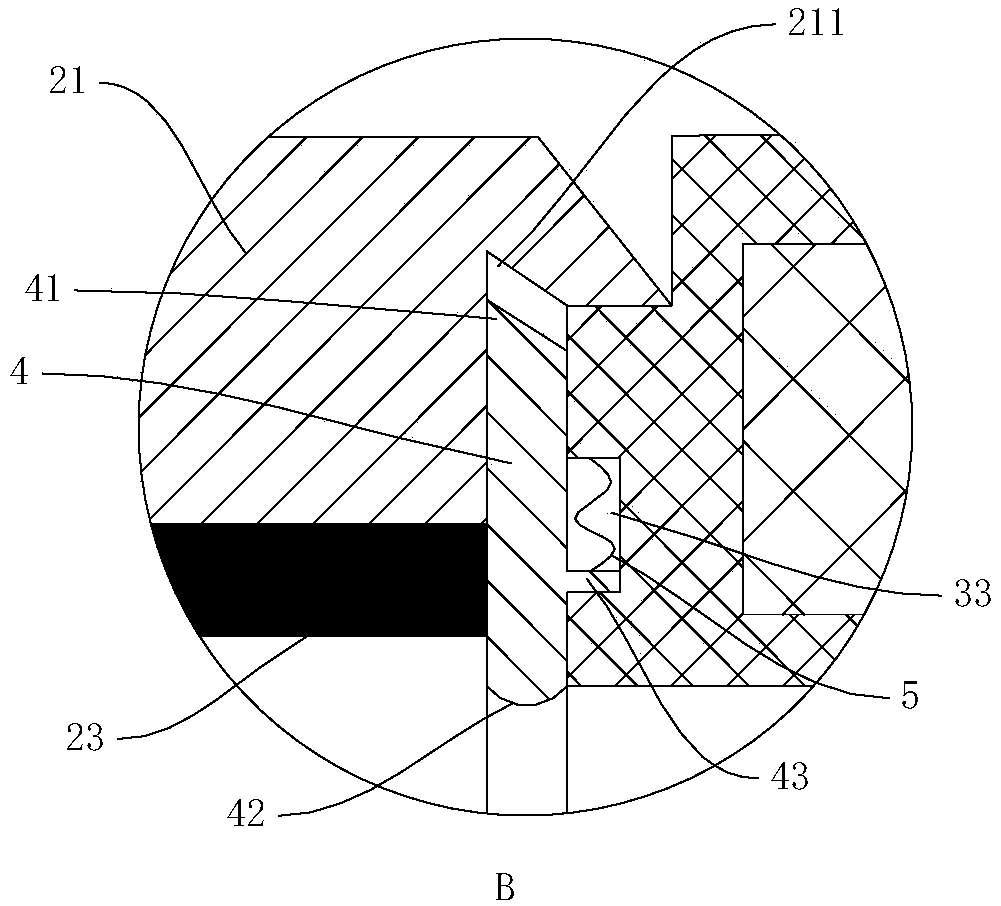

[0025] In this embodiment, for the linear bearing with the oil storage tank 3, refer to the attached Figure 2-8 , the linear bearing still includes the outer ring 21, as well as the balls 22 and the cage 23 arranged therein, and oil storage tanks 3 are respectively arranged at both ends of the outer ring 21. The side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com