Slitting and cutting open pit mining method

A mining method and open-field technology, which is applied in the field of strip-cut open-field mining method, can solve the problems of high loss dilution rate, poor mining safety, and high mining cost, so as to achieve the reduction of dilution loss rate, safety guarantee, Guarantee the effect of recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

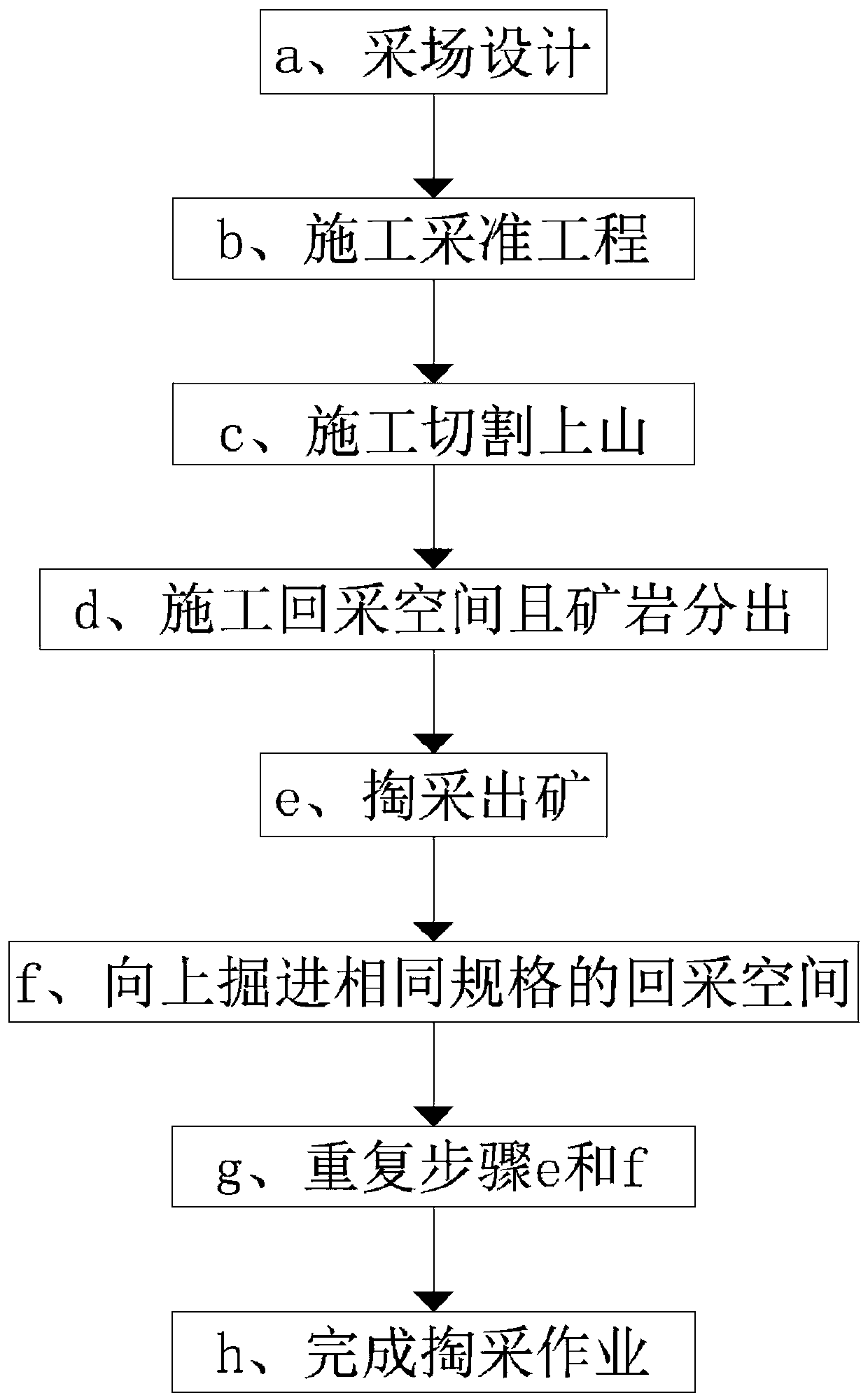

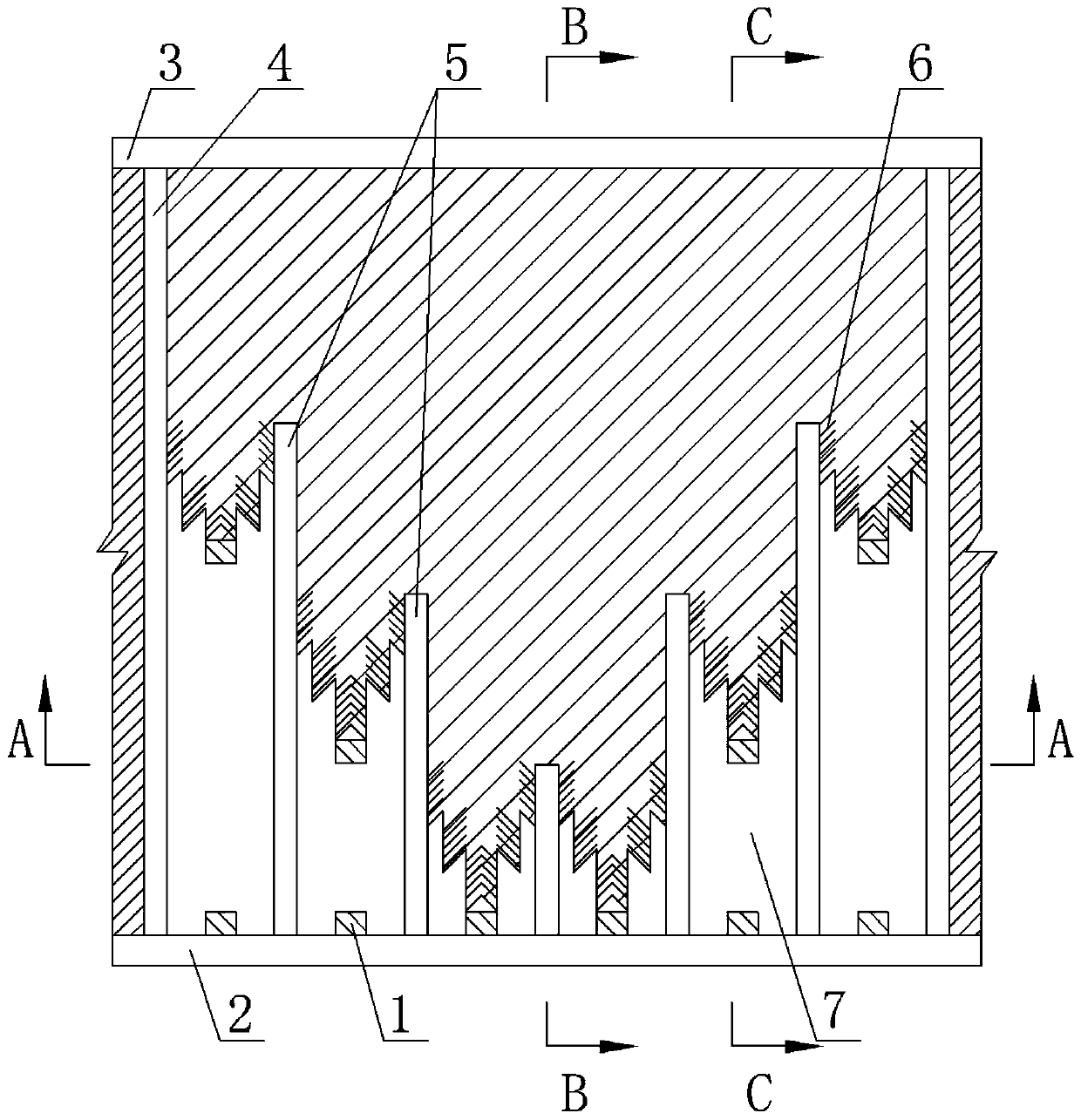

[0047] This slitting of the present invention digs out and cuts type open field mining method, comprises the following steps:

[0048] a. Stope design, arrange the stope along the direction of the ore body, divide the stope into middle section and section along the vertical height of the ore vein, and take the height of the middle section as the stope height;

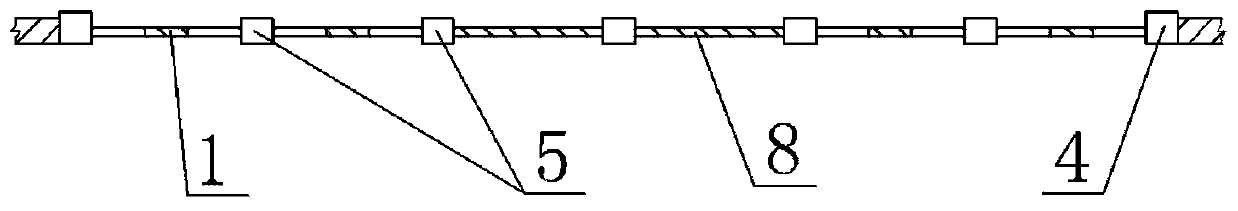

[0049] b. Accurate engineering, arrange the corresponding middle section transportation roadway and subsection transportation roadway at the bottom of the middle section and section;

[0050] c. Cutting works. At both ends of the stope, a cutting uphill that is connected with the middle transportation roadway and the upper section transportation roadway is respectively excavated;

[0051] d. For the mining project, excavate a mining space parallel to the cutting uphill by adopting the method of separate mining and separation of ore and rock every 6 to 8.5m between the two cutting uphills;

[0052] e. Take out the mine: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com