Locking device, single-door drive system and double-door drive system

A locking device and transmission system technology, applied in power transmission/actuator features, electric locks, building locks, etc., can solve the problems of low reliability, high maintenance frequency, easy wear of pins, etc., and achieve low machining accuracy , High maintainability, and the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0055] The invention provides a locking device for a train plug door system based on the principle of self-locking. The locking device can be driven by forward and reverse rotation of a screw rod to open and close the plug door.

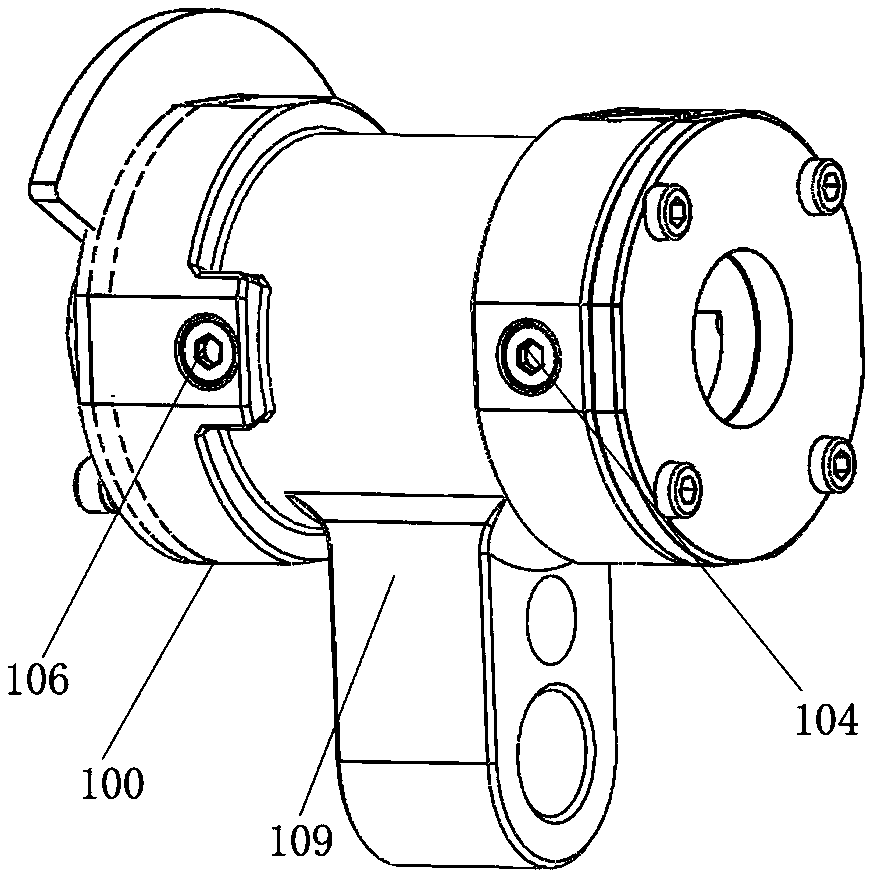

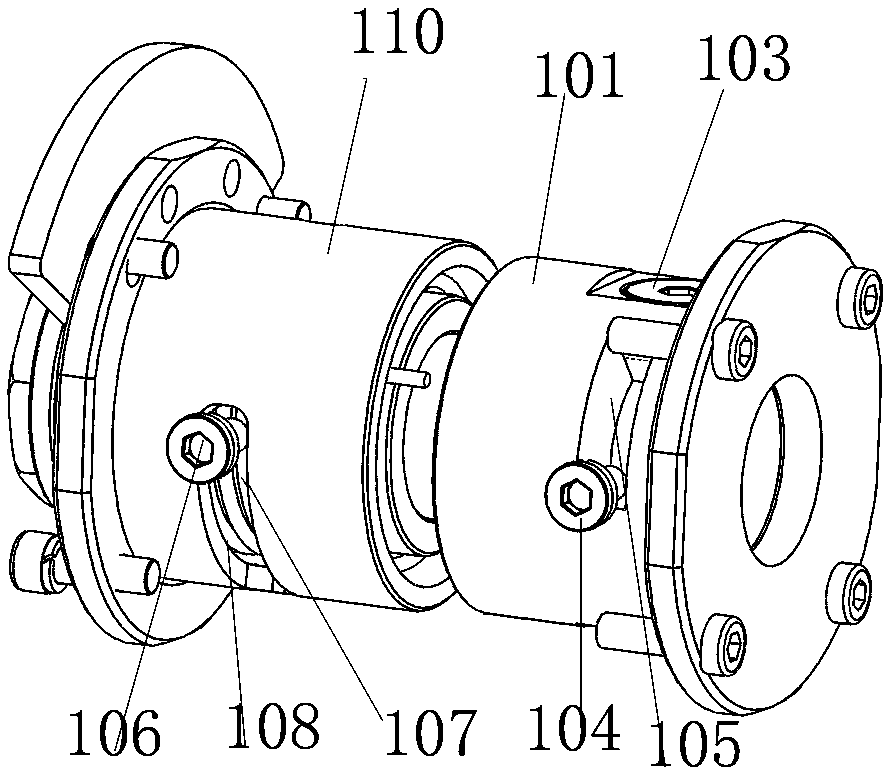

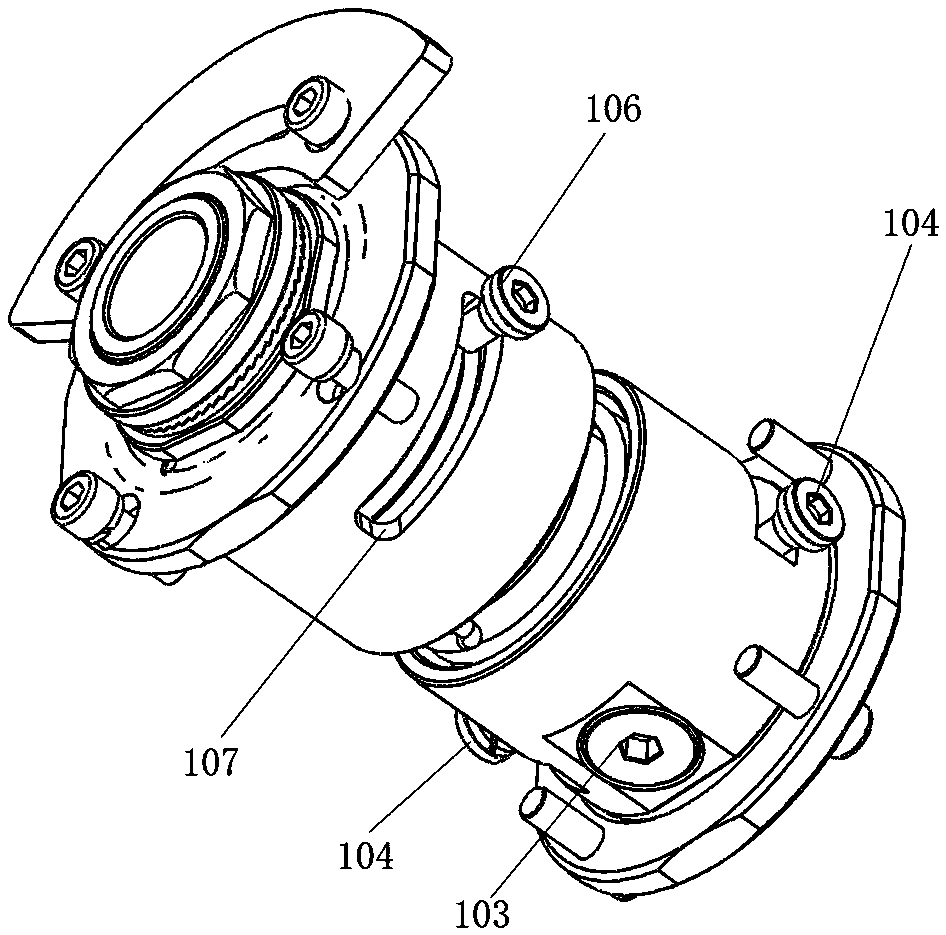

[0056] Such as Figure 1~4 As shown, the device of the present invention includes a screw rod 5, and the door lock device 100 is installed on the screw rod 5, and operates with the rotation of the screw rod.

[0057] Specifically, the door lock device includes a locking block adjacent to the nut pair of the screw mandrel 5, and the locking block can move axially with the nut pair on the screw mandrel 5; the nut pair is an inherent device on the screw mandrel 5, The nut pair can move on the screw mandrel 5 under the rotation of the screw mandrel 5 . It also includes a locking groove provided on the screw ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com