Method for resourceful full-mass utilization of rape stalks

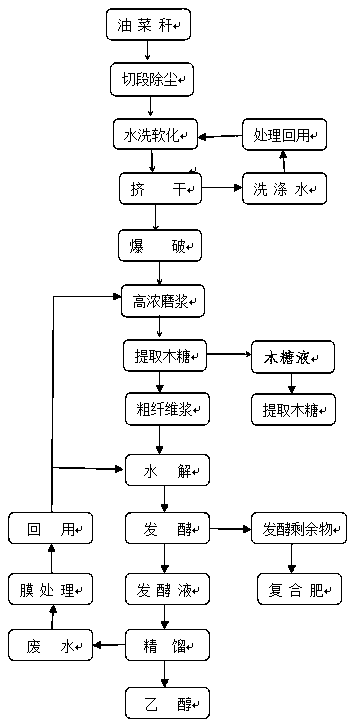

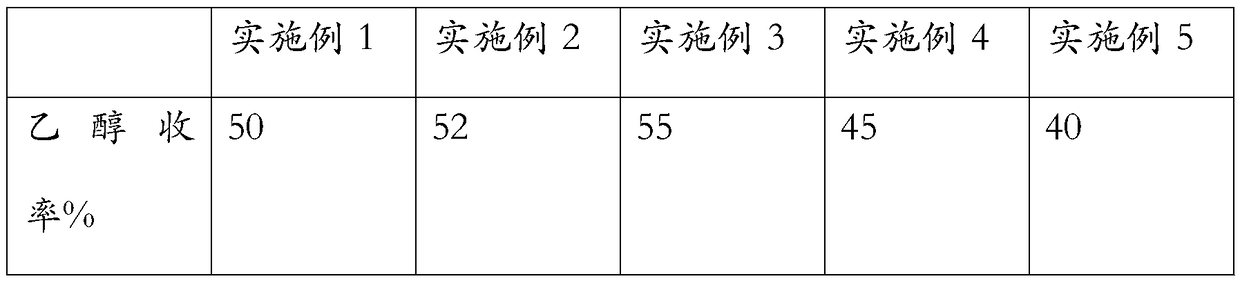

A rapeseed stalk and recycling technology, applied in the direction of chemical instruments and methods, biochemical equipment and methods, methods based on microorganisms, etc., can solve the problem that the cellulosic ethanol industry is difficult to break through the technical and economic barriers, cannot realize industrialized production, and the production cost Increase and other issues, to achieve the effect of reducing equipment investment, eliminating the effect of feedback inhibition, and improving alcohol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Rapeseed straw is crushed with a hammer mill. Its core working components are hammers and sieve plates. When working, the hammers begin to rotate at a high speed, continuously hitting the straws to destroy the structure, which conforms to 1-3cm The required rape stalks are discharged through the sieve plate holes, and the hammers continue to hit the unqualified straws. When the straws are crushed to meet the requirements, they are then discharged from the sieve holes for dust removal to remove impurities and dust; rape stalks after dust removal , There are still some soil and other impurities. In order to remove these impurities and soften the rape stalks, in order to facilitate the blasting, use 85 ℃ hot water to wash in the spiral grass washer. The grass washer is an oblique spiral. The lower part enters, the rape straw enters from the upper part, and the temperature is maintained by steaming into the outer jacket of the lawn washer. The rape straw washed with hot ...

Embodiment 2

[0052] Rapeseed straws are crushed with a hammer mill. The core working components are hammers and sieve plates. When working, the hammers begin to rotate at a high speed, continuously hitting the straws and destroying the structure. Rapeseed that meets the requirements of 1-3cm The rods are discharged through the sieve plate holes, and the hammers continue to hit the unqualified straws. When the straws are crushed to meet the requirements, they are then discharged from the sieve holes for dust removal to remove impurities and dust; the rape straw after dust removal is still entrained There are some soil and other impurities. In order to remove these impurities and soften the rape stalks, in order to facilitate the blasting, use 85℃ hot water to carry out countercurrent washing in a spiral grass washer. The grass washer is an inclined spiral and the water enters from the bottom. The rape stalks enter from above, and the temperature is maintained by steaming through the outer jac...

Embodiment 3

[0056] Rapeseed straws are crushed with a hammer mill. The core working components are hammers and sieve plates. When working, the hammers begin to rotate at a high speed, continuously hitting the straws and destroying the structure. Rapeseed that meets the requirements of 1-3cm The rods are discharged through the sieve plate holes, and the hammers continue to hit the unqualified straws. When the straws are crushed to meet the requirements, they are then discharged from the sieve holes for dust removal to remove impurities and dust; the rape straw after dust removal is still entrained There are some soil and other impurities. In order to remove these impurities and soften the rape stalks, in order to facilitate the blasting, use 85℃ hot water to carry out countercurrent washing in a spiral grass washer. The grass washer is an inclined spiral and the water enters from the bottom. The rape stalks enter from above, and the temperature is maintained by steaming through the outer jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com