Tower crane lifting dead-slow control system and method

A control system and control method technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of lack of micro-speed control working mode, prone to hoisting quality accidents, affecting work efficiency, etc., and achieve convenient human-computer interaction interface, The effect of lifting safety and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] With reference to the accompanying drawings, the present invention will be further explained by taking the hoisting motor in normal state f=50Hz, rated speed V=92m / min, acceleration time T1=deceleration time T3=4s, and fine speed frequency f1=3Hz.

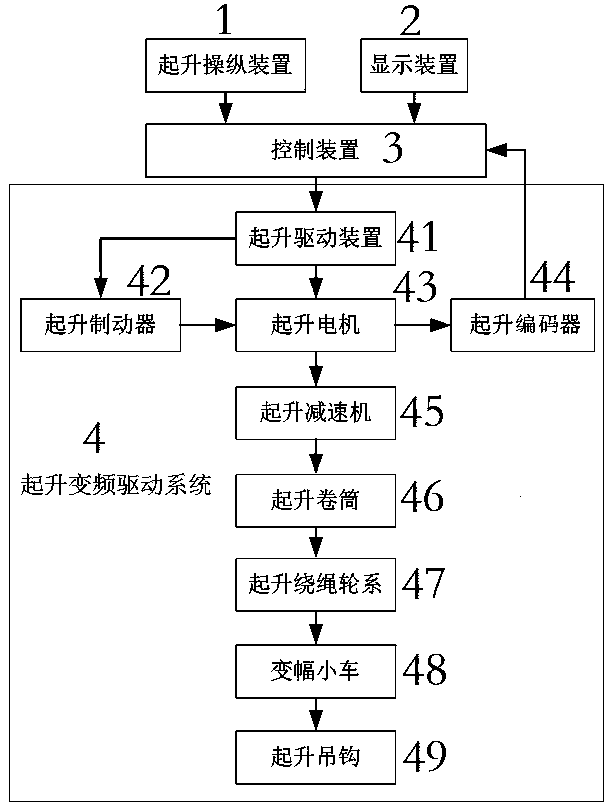

[0018] Such as figure 1 As shown, a tower crane hoisting micro-speed control system includes a control device 3 connected with a display device 2 for providing an interpersonal interface and simultaneously displaying information such as tower crane working mode, operating parameters, parameter settings, and alarms. ; Connected with a lifting control device 1 for a given tower crane operation control signal; connected with a lifting variable frequency drive system 4 for executing a lifting command of the control device.

[0019] Further, the hoisting variable frequency drive system 4 includes a hoisting drive device connected to the control device and used for executing operation control commands, controlling the operation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com