Adjustable crane hook and manufacturing method thereof

A crane, adjustable technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of time-consuming and laborious, low work efficiency, inconvenient operation, etc., and achieve the effect of improving safety, convenient operation and multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

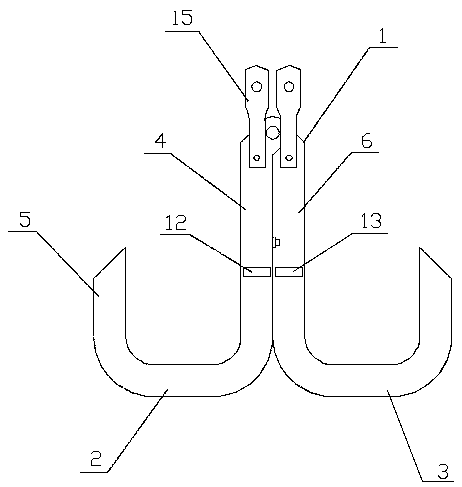

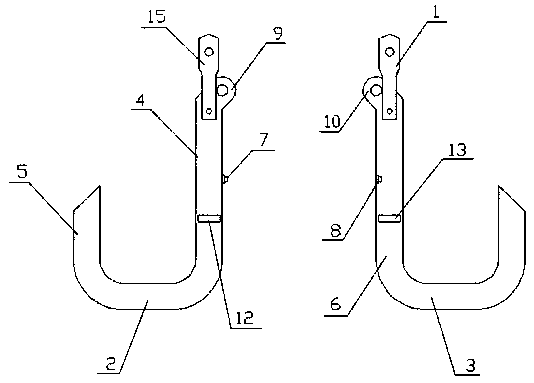

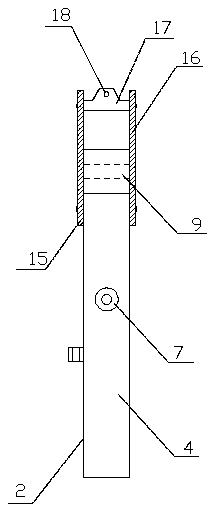

[0033] This embodiment provides an adjustable crane hook, such as figure 1 , 2,3 shown, including hook body 1, hook body 1 includes left hook 2 and right hook 3. Left hook 2 comprises left connecting plate 4, and right suspension hook 3 comprises right connecting plate 6, and the lower end of left connecting plate 4 and right connecting plate 6 is all provided with hook head 5, and the front and back of left connecting plate 4 and right connecting plate 6 upper ends Both sides are respectively hinged with a first side plate 15 and a second side plate 16, and lifting lugs are installed between the first side plate 15 and the second side plate 16, and the two ends of the lifting lugs are connected with the first side plate 15 and the second side plate respectively. The two side plates 16 are hinged, and a through hole 18 is provided on the lifting lug, and the traction rope passes through the through hole 18 and is connected with the lifting lug.

[0034] The right side of the ...

Embodiment 2

[0043] This embodiment provides an adjustable crane hook, such as Figure 5As shown, a hook body 1 is included, and the hook body 1 includes a left hook 2 and a right hook 3 . Left hook 2 comprises left connecting plate 4, and right suspension hook 3 comprises right connecting plate 6, and the lower end of left connecting plate 4 and right connecting plate 6 is all provided with hook head 5, and the front and back of left connecting plate 4 and right connecting plate 6 upper ends Both sides are respectively hinged with a first side plate 15 and a second side plate 16, and lifting lugs are installed between the first side plate 15 and the second side plate 16, and the two ends of the lifting lugs are connected with the first side plate 15 and the second side plate respectively. The two side plates 16 are hinged, and a through hole 18 is provided on the lifting lug, and the traction rope passes through the through hole 18 and is connected with the lifting lug.

[0044] The righ...

Embodiment 3

[0053] This embodiment provides an adjustable crane hook, such as Figure 4 As shown, a hook body 1 is included, and the hook body 1 includes a left hook 2 and a right hook 3 . Left hook 2 comprises left connecting plate 4, and right suspension hook 3 comprises right connecting plate 6, and the lower end of left connecting plate 4 and right connecting plate 6 is all provided with hook head 5, and the front and back of left connecting plate 4 and right connecting plate 6 upper ends Both sides are respectively fixed and hinged with a first side plate 15 and a second side plate 16, and lifting lugs are installed between the first side plate 15 and the second side plate 16, and the two ends of the lifting lugs are connected with the first side plate 15 and the second side plate 16 respectively. The second side plate 16 is hinged, and a through hole 18 is opened on the lifting lug, and the traction rope passes through the through hole 18 and is connected with the lifting lug. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com