Punching device for automotive interior trim production

A technology for automotive interior parts and mounting panels, applied in metal processing and other directions, can solve the problems of time-consuming and laborious, poor work accuracy, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

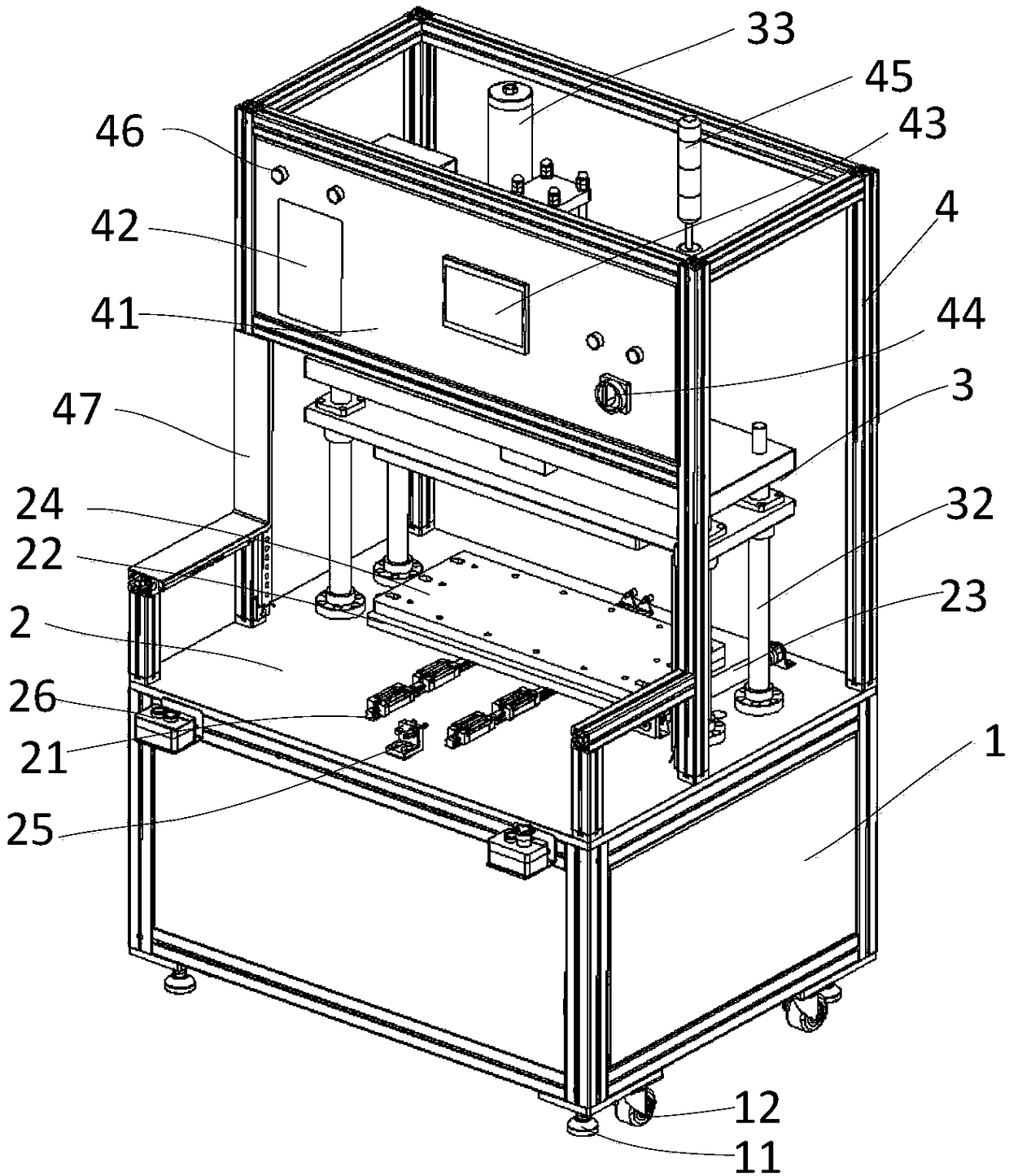

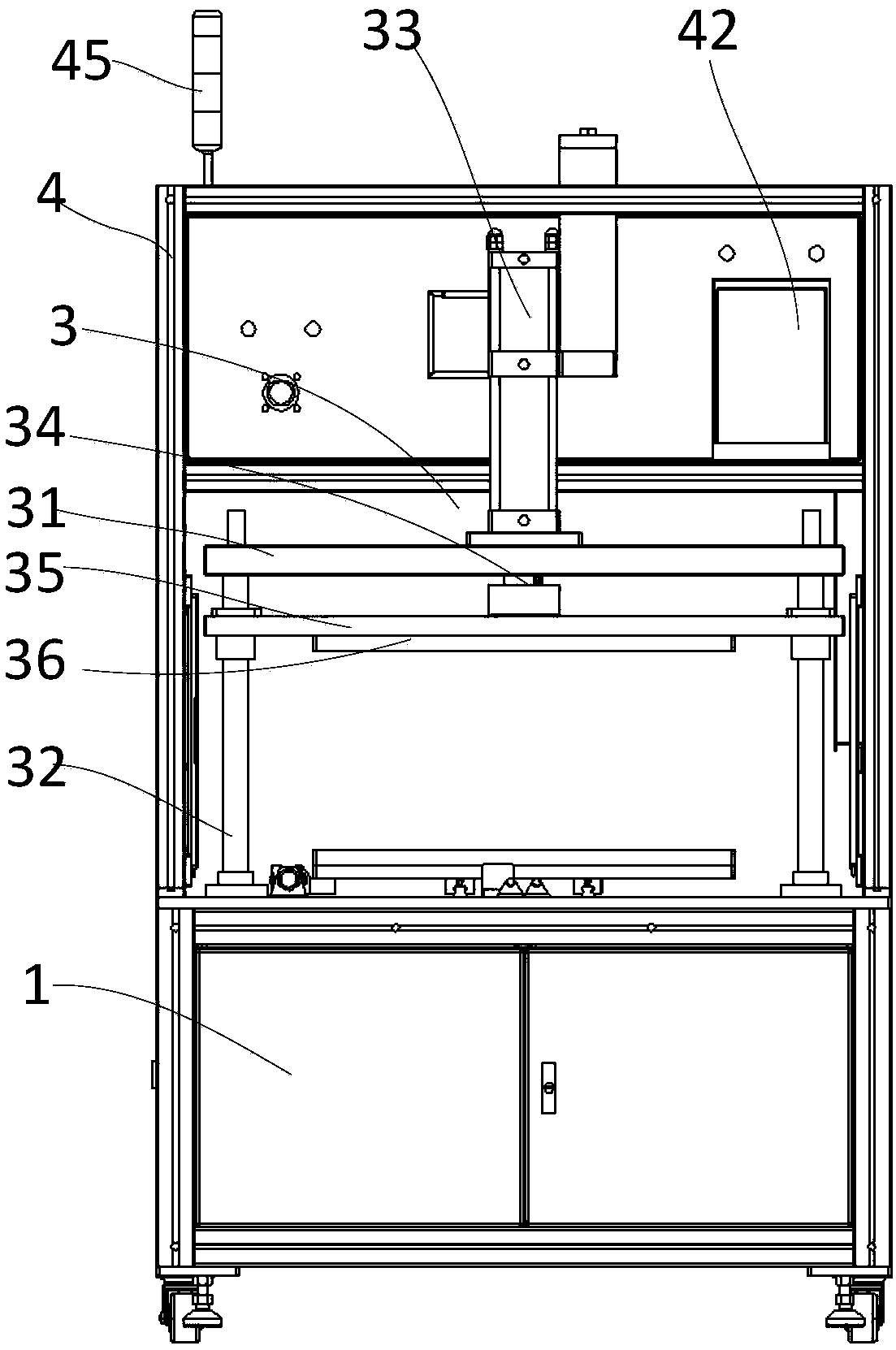

[0020] Such as Figure 1-2 As shown, a punching device for the production of automotive interior parts includes a base 1 and a workbench 2 arranged on the base 1. The middle part of the workbench 2 is provided with a plurality of slide rails 21 transversely. Plate 22, a displacement cylinder 23 is arranged laterally on one side of the sliding mounting plate 22, a lower mold 24 is arranged on the sliding mounting plate 22, and a punching mechanism 3 is arranged above the lower mold 24, and the punching mechanism 3 includes a punching mounting plate 31, punching Cutting mounting plate 31 is provided with supporting column 32 around, and punching mounting plate 31 top is provided with booster cylinder 33, and boosting cylinder 33 comprises push rod 34, and push rod 34 passes through punching mounting plate 31, is connected with Push plate 35, upper film 36 is provided on the push plate 35, support 4 is provided on the outer workbench 2 of punching mechanism 3, front panel 41 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com