A chemical reaction device and its working method

A technology for chemical reactions and working methods, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical/physical processes, etc. Stable fixation and other issues, to achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

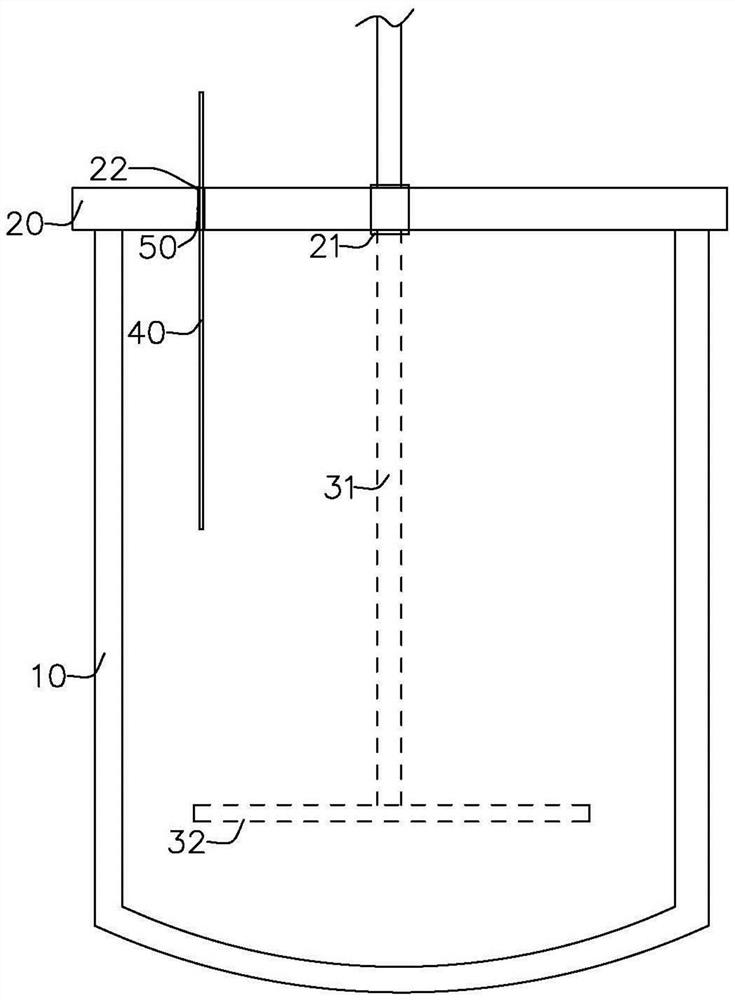

[0029] Such as Figure 1 to Figure 3 As shown, the chemical reaction device of this embodiment includes a container body 10, a cover body 20 and a stirring assembly.

[0030] The cover body 20 is disposed on the upper part of the containing body 10 , and the cover body 20 is detachably connected with the containing body 10 . The cover body 20 has a first opening 21 and a second opening 22 .

[0031] The stirring assembly has a rod body 31 connected to each other and a stirring unit 32 , the rod body 31 passes through the first opening 21 , and the stirring unit 32 is arranged in the containing body 10 .

[0032] The thermometer 40 passes through the second opening 22 , and the lower part of the thermometer 40 is disposed in the containing body 10 .

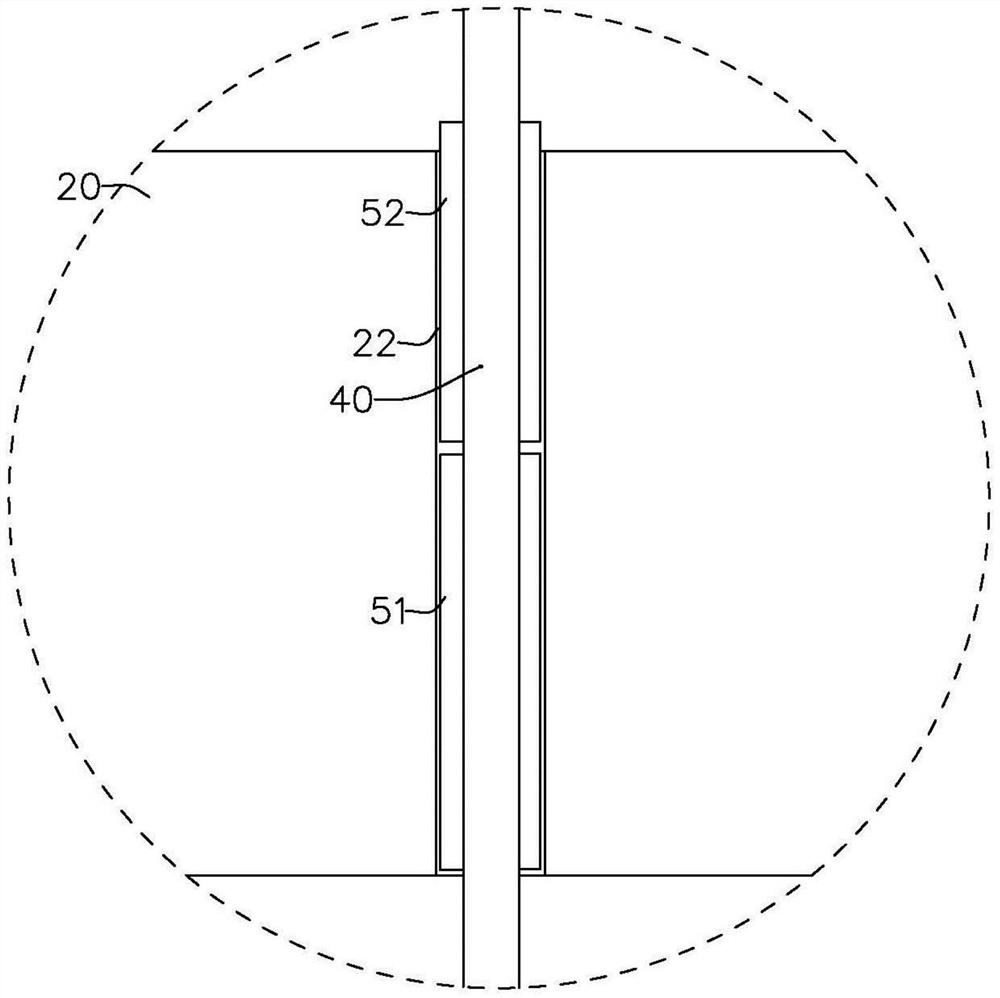

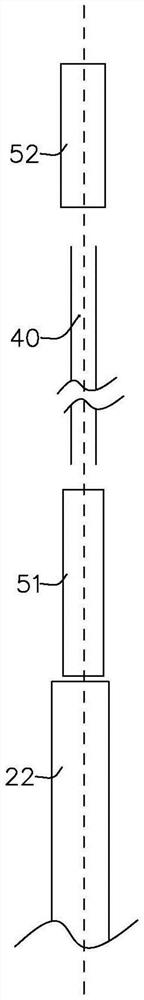

[0033] Wherein, the position of the second opening 22 is provided with a clamping device 50, the clamping device 50 includes an elastic clamping body 51 and a moving part 52, the moving part 52 is rotatably connected with the se...

no. 2 example

[0039] The chemical reaction device of this embodiment is basically the same as that of the first embodiment above, and only the differences will be described in detail below.

[0040] Such as Figure 4 with Figure 5As shown, the elastic clamping body 51 of this embodiment includes a first elastic body 53 and a second elastic body 54 , and the thermometer 40 is disposed between the first elastic body 53 and the second elastic body 54 . The second opening 22 has an internal thread, and the moving member 52 has an external thread matching the internal thread.

[0041] This working method comprises the following steps: the external thread rotates and moves in the vertical direction relative to the internal screw, thereby realizing the moving part 52 moving in the vertical direction relative to the second opening 22, and the moving part 52 is relative to the first elastic body 53 and The second elastic body 54 plays a role of resisting extrusion, the first elastic body 53 elast...

no. 3 example

[0043] The chemical reaction device of this embodiment is basically the same as that of the first embodiment above, and only the differences will be described in detail below.

[0044] Such as Figure 4 with Figure 5 As shown, the second opening 22 of this embodiment has an upper portion 24 and a lower portion 25, the inner diameter of the lower portion 25 gradually decreases, the width of the first elastic body 53 gradually decreases from top to bottom, and the width of the second elastic body 54 gradually shrinks from top to bottom.

[0045] The second opening 22 includes an upper opening 26 disposed on the upper portion of the upper portion 24 and a lower opening 27 disposed on the lower portion of the lower portion 25 .

[0046] This working method comprises the following steps: the moving member 52 gradually moves from the upper section 24 to the lower section, so that the first elastic body 53 and the second elastic body 54 form a convex deformation in the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com