Lithium battery slurry agitator

A mixer and lithium battery technology, which is applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., can solve the problems of poor stability, short service life, and difficult movement of the device, and achieve enhanced uniformity and guaranteed performance , Simplify the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

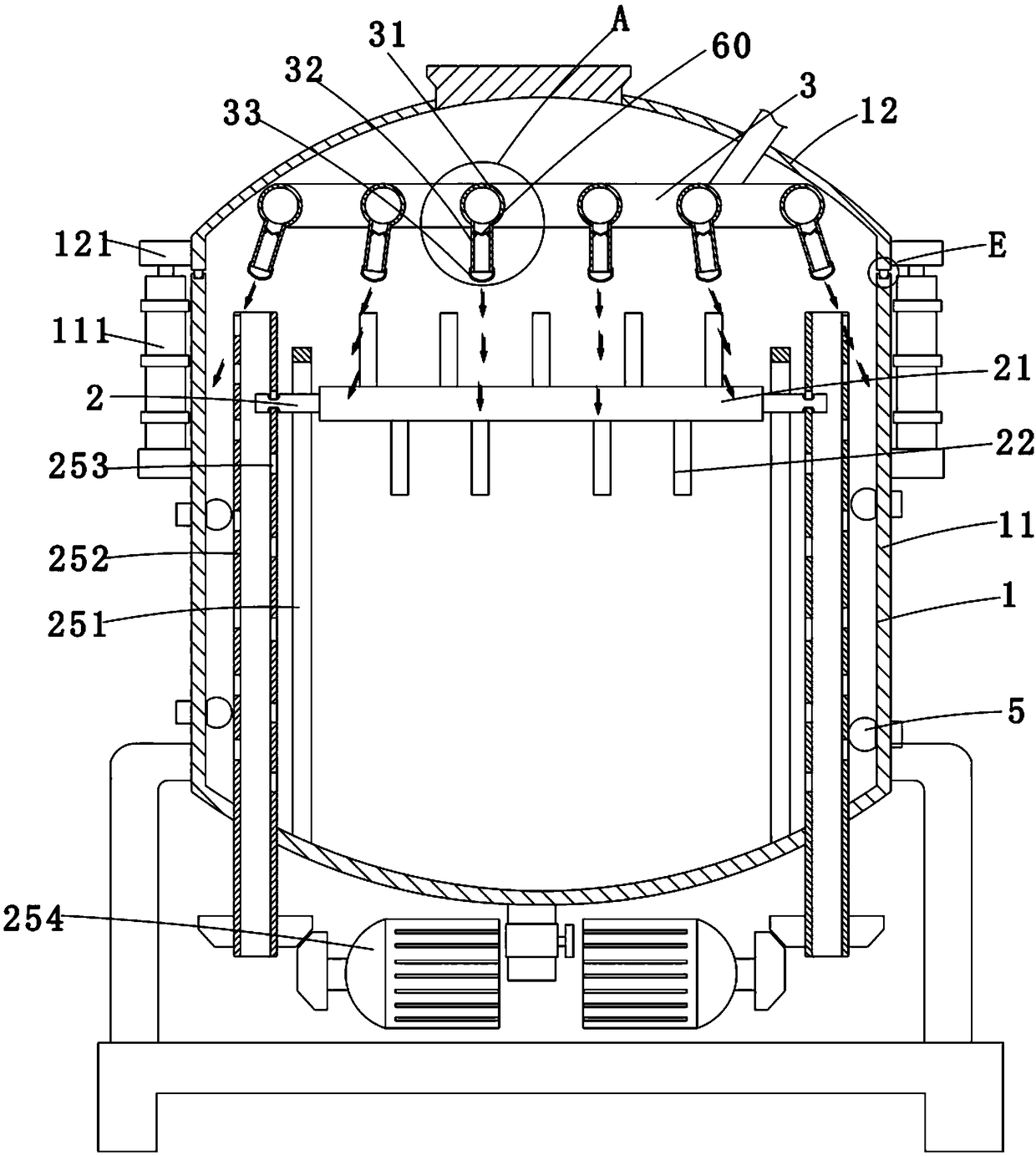

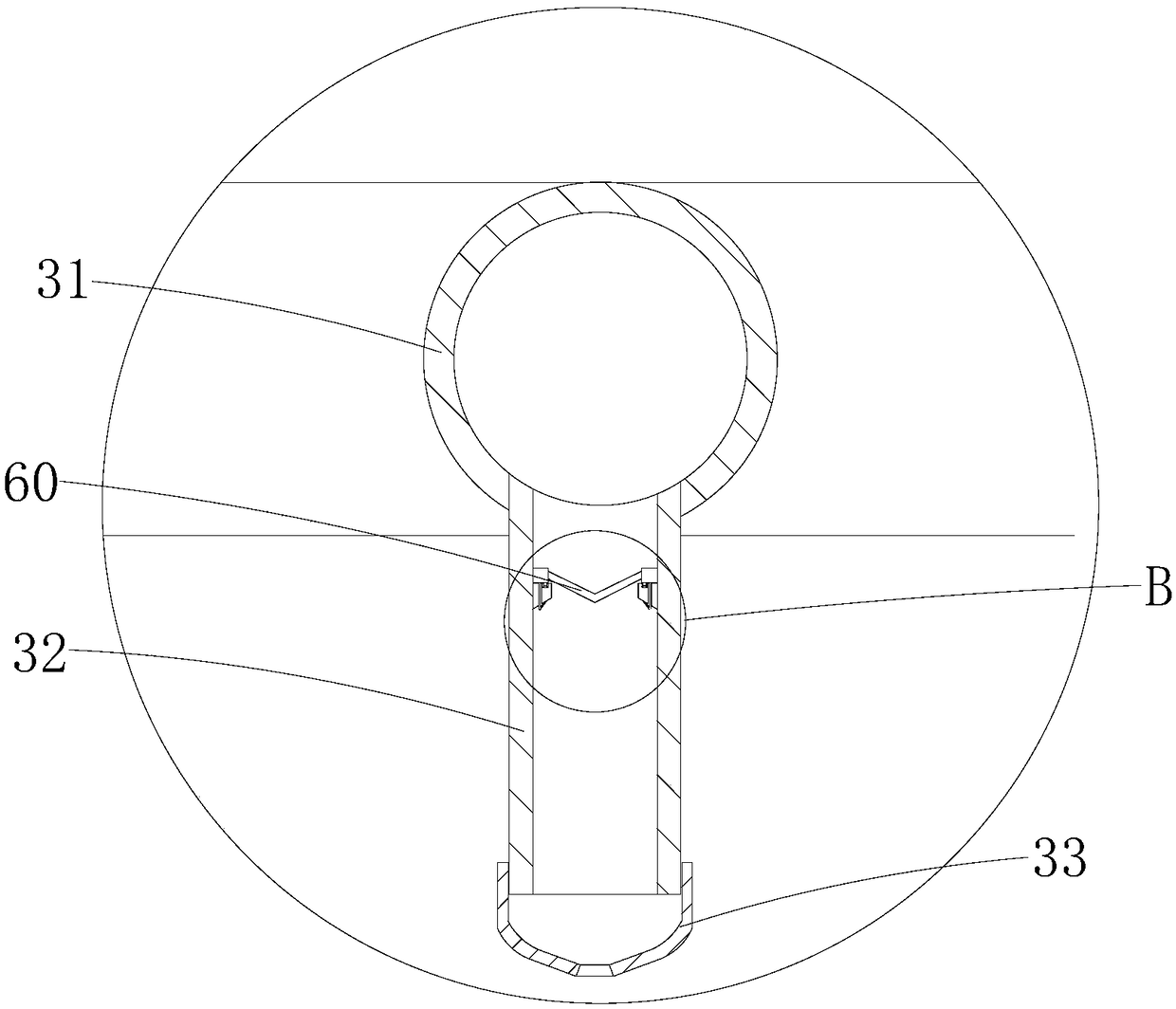

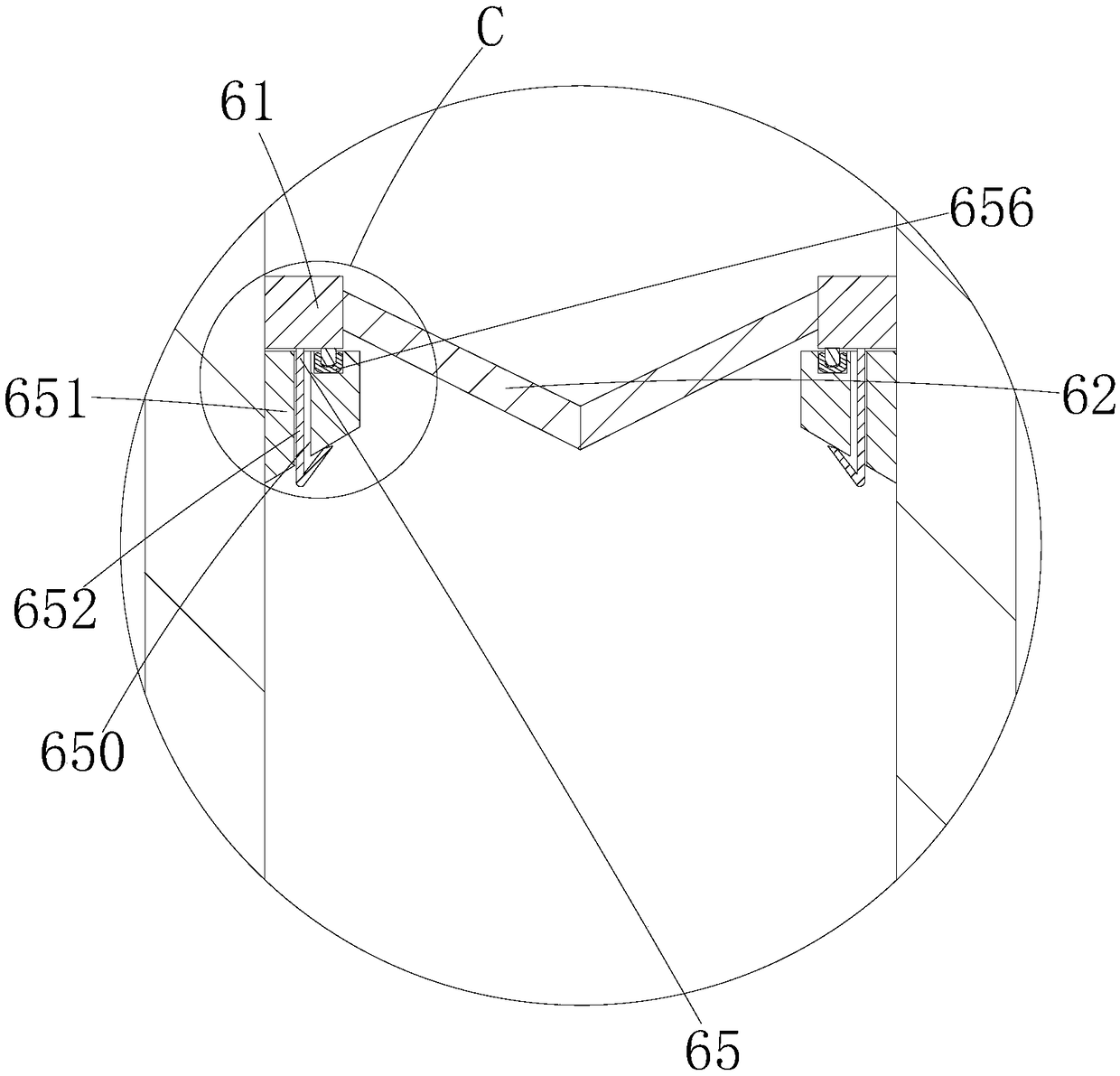

[0034] Such as Figure 1-9 As shown, a lithium battery slurry mixer includes a material tank 1, a stirring device 2, a cleaning component 3, a vacuum component 4 and an ultrasonic component 5, the material tank 1 includes a tank body 11 and a cover body 12, and the tank The body 11 is a metal bucket, and the cover 12 is also a metal cover. The cover 12 can be covered on the tank body 11, and the cover 12 is provided with a connecting ear 121. On the tank body 11 A cylinder 111 is fixed on the side wall, and the end of the cylinder 111 is connected to the connecting ear 121, so that the cover 12 can be opened under the push of the cylinder 111, and the cover 12 can be opened in the cylinder 111. Under the connection of the cylinder 111, the pulling force of the cylinder 111 pulls the cover body 12 tightly and covers it on the tank body 11; a layer of elastic seal 122 is bonded on the lower end surface of the cover body 12, and the elastic seal member 122 It is an O-shaped seal...

Embodiment 2

[0044] Such as Figure 10-11 As shown, the difference between this embodiment and Embodiment 1 is that this implementation discloses the base part 7 for supporting the material tank 1, specifically: the base part 7 includes a base 71, a support frame 72, a ball 73 and a Vibration spring 74, described base 71 is a metal plate, and described support frame 72 is two, and one links to each other with described tank body 11, and another one links to each other with described base 71, and described damping spring 74 is set Between the support frames 72 at both ends and connected to the support frames 72, the balls 73 are arranged on the four corners of the base 71, and the balls 73 are metal balls; specifically, the support frames 72 A support platform 721 is provided, and the support platform 721 is a metal platform, and a positioning tube 722 is arranged on the support platform 721, and the shock absorbing spring 74 is inserted into the positioning tube 722, and is placed on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com