Automatic feeding device for chicken breeding

An automatic feeding device and feeding technology, applied in the field of chicken breeding equipment, can solve the problems of low degree of automation, inconvenient feeding, easy to catch cold and sick, and achieve the effect of controllable feeding speed, flexible use and ensuring healthy growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

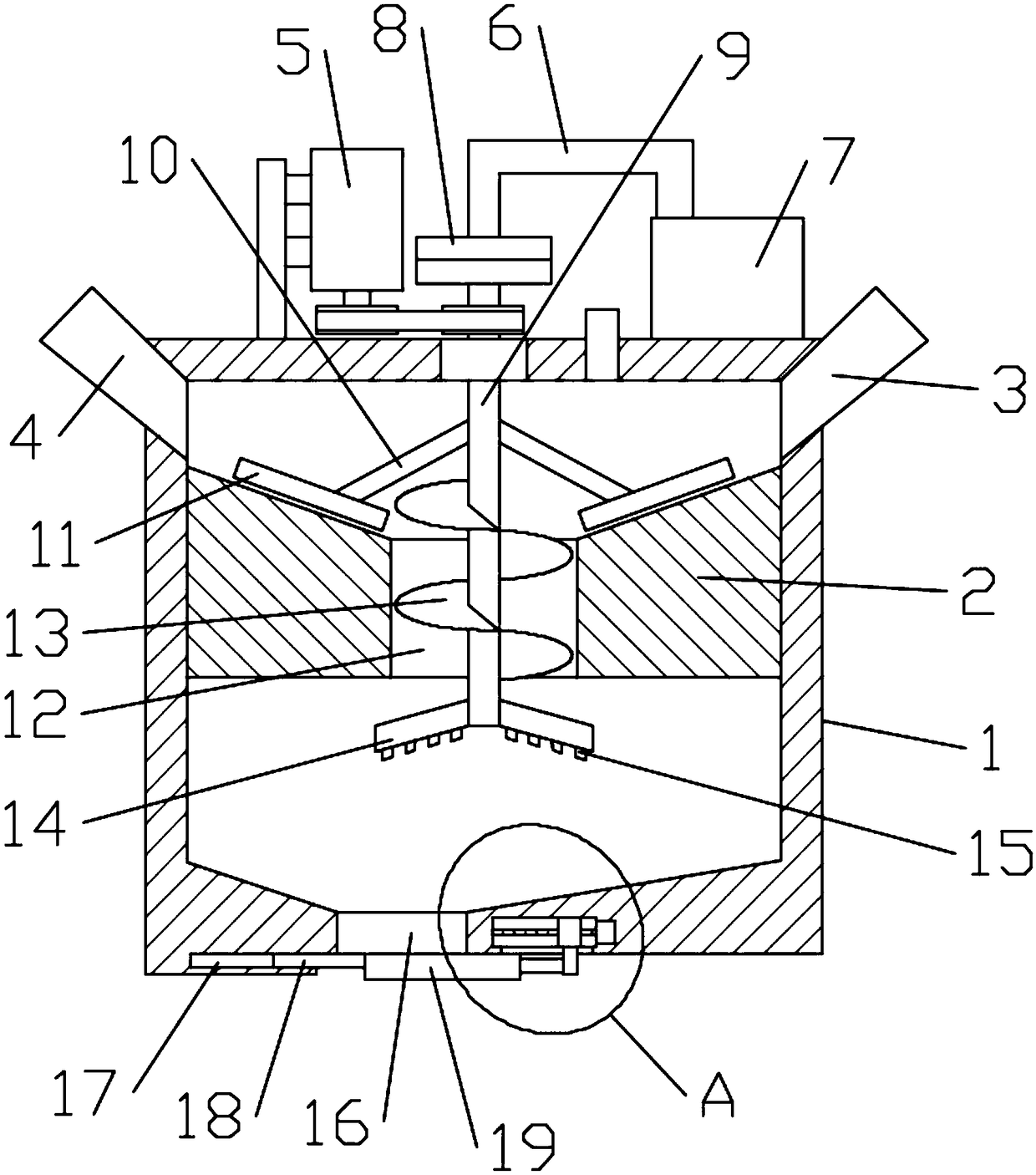

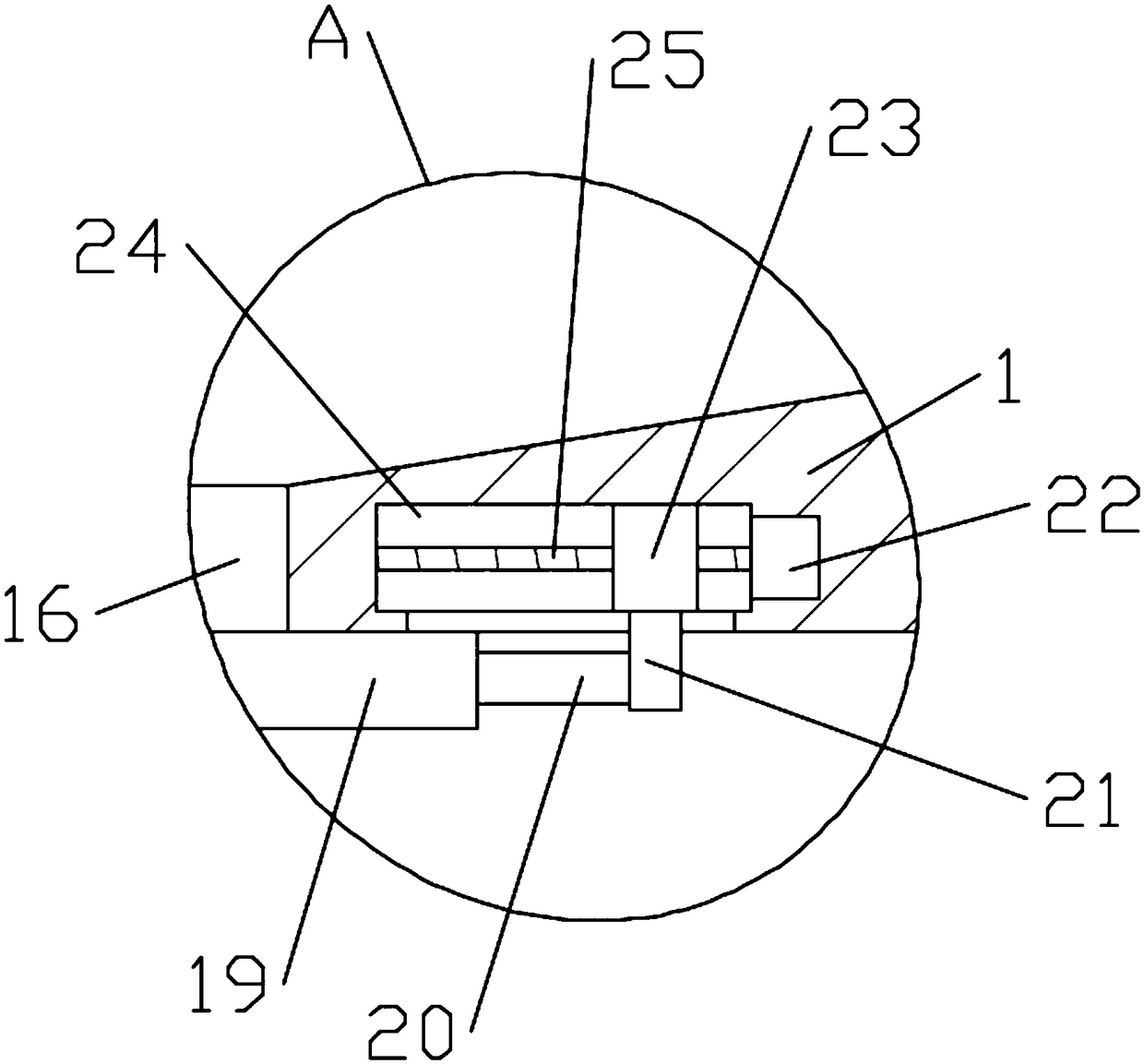

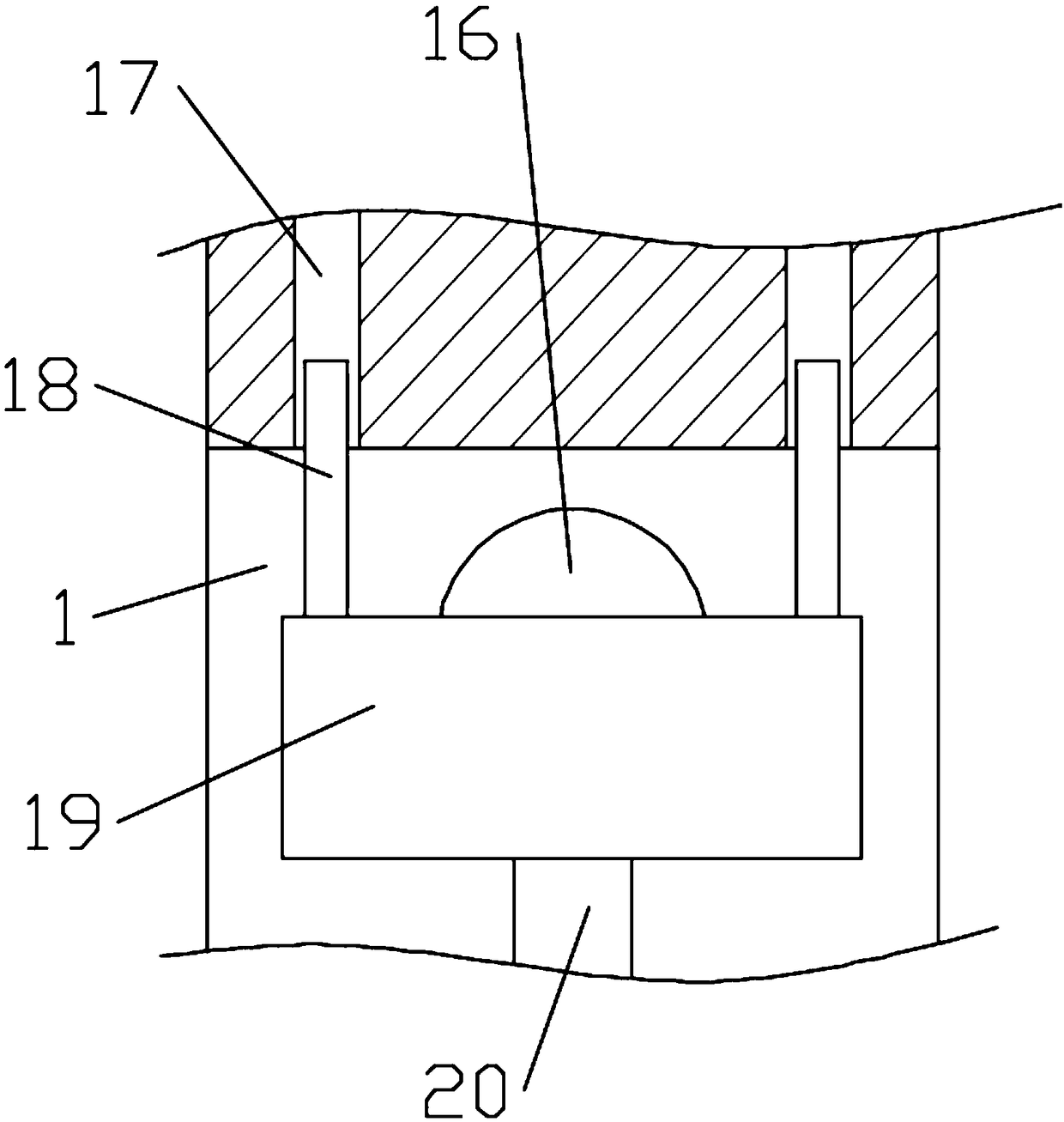

[0020] see Figure 1~3 , in the embodiment of the present invention, an automatic feeding device for chicken breeding, comprising a box body 1, a partition plate 2 is fixedly arranged inside the box body 1, and the upper surface of the partition plate 2 is arranged at an inclination with the middle low and the two ends high, The middle part of the dividing plate 2 is provided with a blanking channel 12, and a rotating rod 9 is penetrated in the discharging channel 12, and the top of the rotating rod 9 is rotated through the top plate of the casing 1, and the upper part of the rotating rod 9 A support rod 10 is fixedly installed on the outer ring, and the bottom end of the support rod 10 is fixedly connected with a stirring rod 11 matched with the inclined surface of the upper surface of the partition plate 2, and a spiral blade 13 is arranged on the rotating rod 9 inside the spiral blade 13. The stirring motor 5 that is used to drive the rotating rod 9 to rotate is fixedly ins...

Embodiment 2

[0025] Different from Embodiment 1, the rotating rod 9 adopts a hollow tube, and a hot air blower 7 is fixedly installed on the top plate of the box body 1, and the air outlet end of the hot air blower 7 is connected with a vent pipe 6, and the other end of the vent pipe 6 is connected to the air pipe 6. The tops of the rotating rods 9 are rotatably connected by a rotary joint 8, and the bottom end of the rotating rods 9 in the casing 1 is fixedly equipped with an exhaust pipe 14. The exhaust pipe 14 adopts a hollow pipe, and the inner part of the exhaust pipe 14 The cavity communicates with the lower inner cavity of the rotating rod 9. Further, the lower surface of the exhaust pipe 14 is equidistantly provided with a number of blowing ports 15 for discharging the air in the exhaust pipe 14. In this embodiment, the heat The hot air that blower fan 7 produces is injected in the rotating bar 9 through vent pipe 6, and then the hot air in rotating bar 9 is discharged by blowing po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com