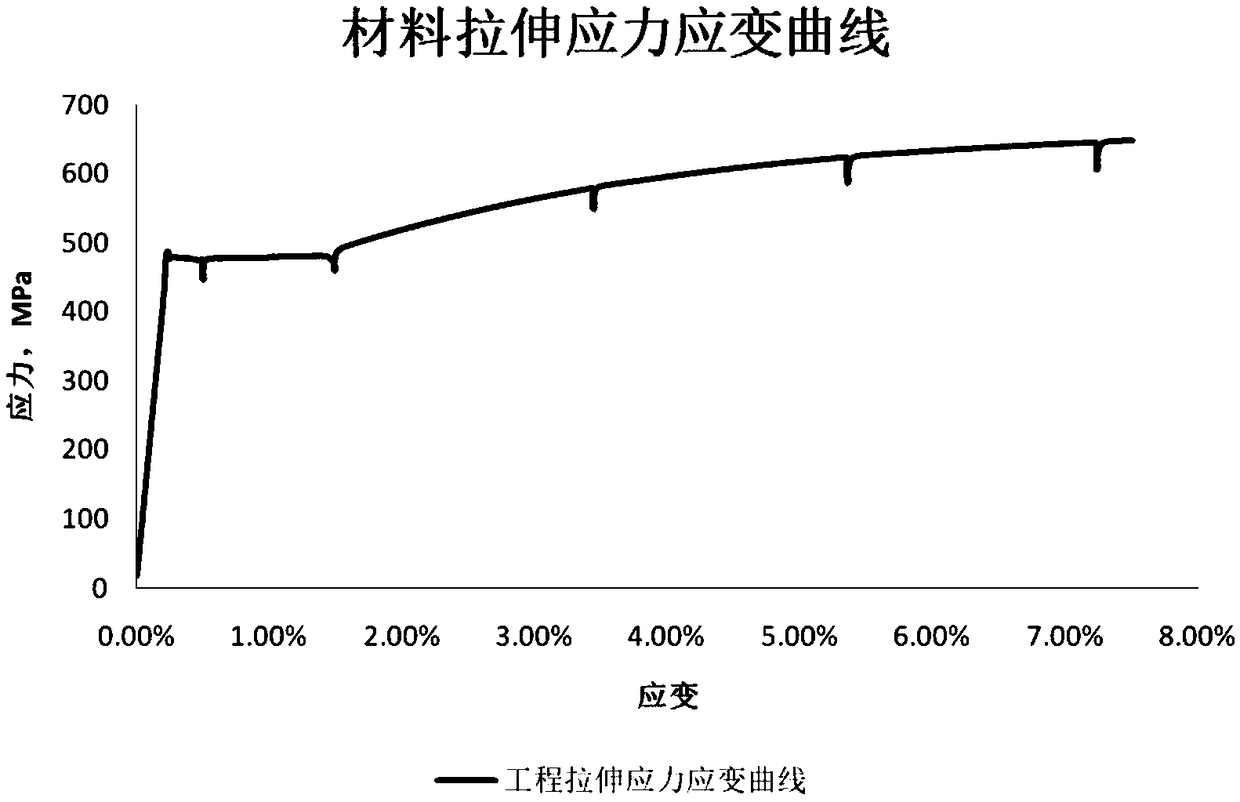

Method used for obtaining stress-strain curve of metal materials at static tensile states

A stress-strain curve, metal material technology, applied in the direction of analyzing materials, applying stable tension/pressure to test material strength, measuring devices, etc., can solve the problem of high cost of experiment time, inability to effectively simulate long-term force use, and inability to obtain Material tensile curve and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

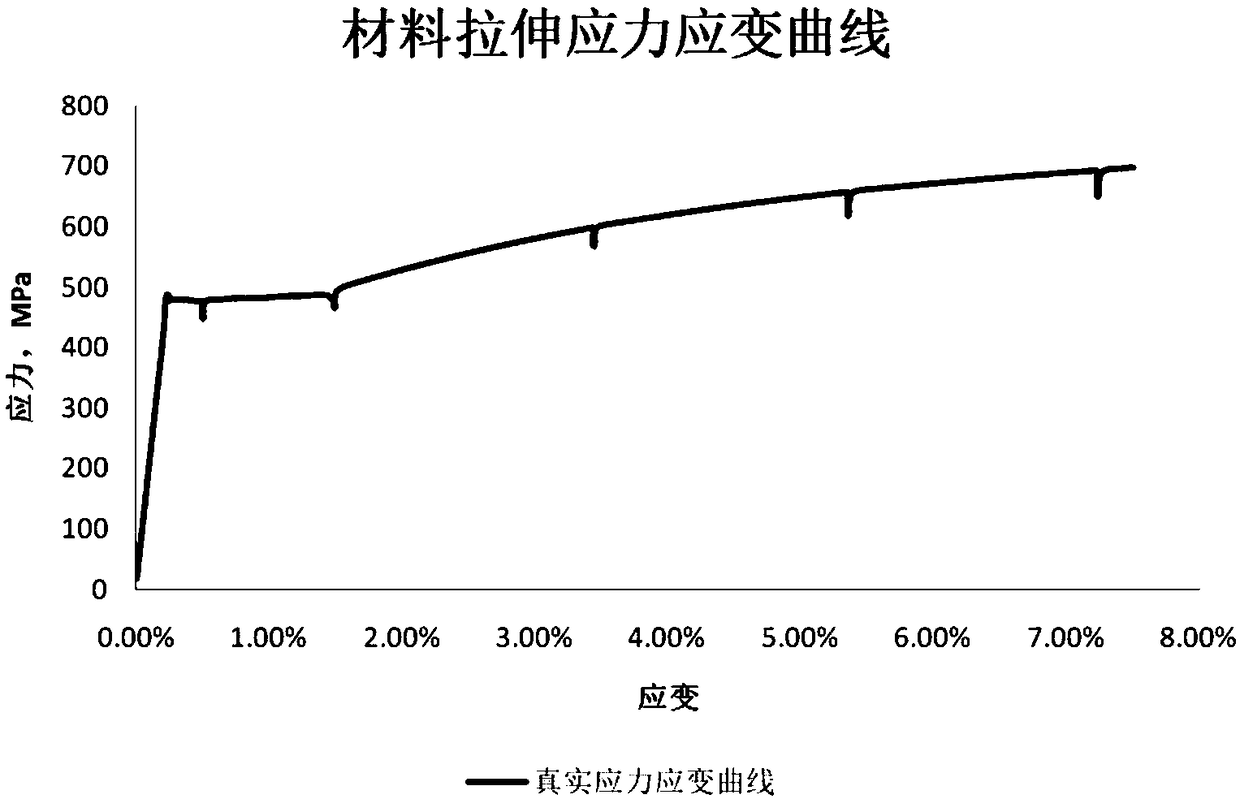

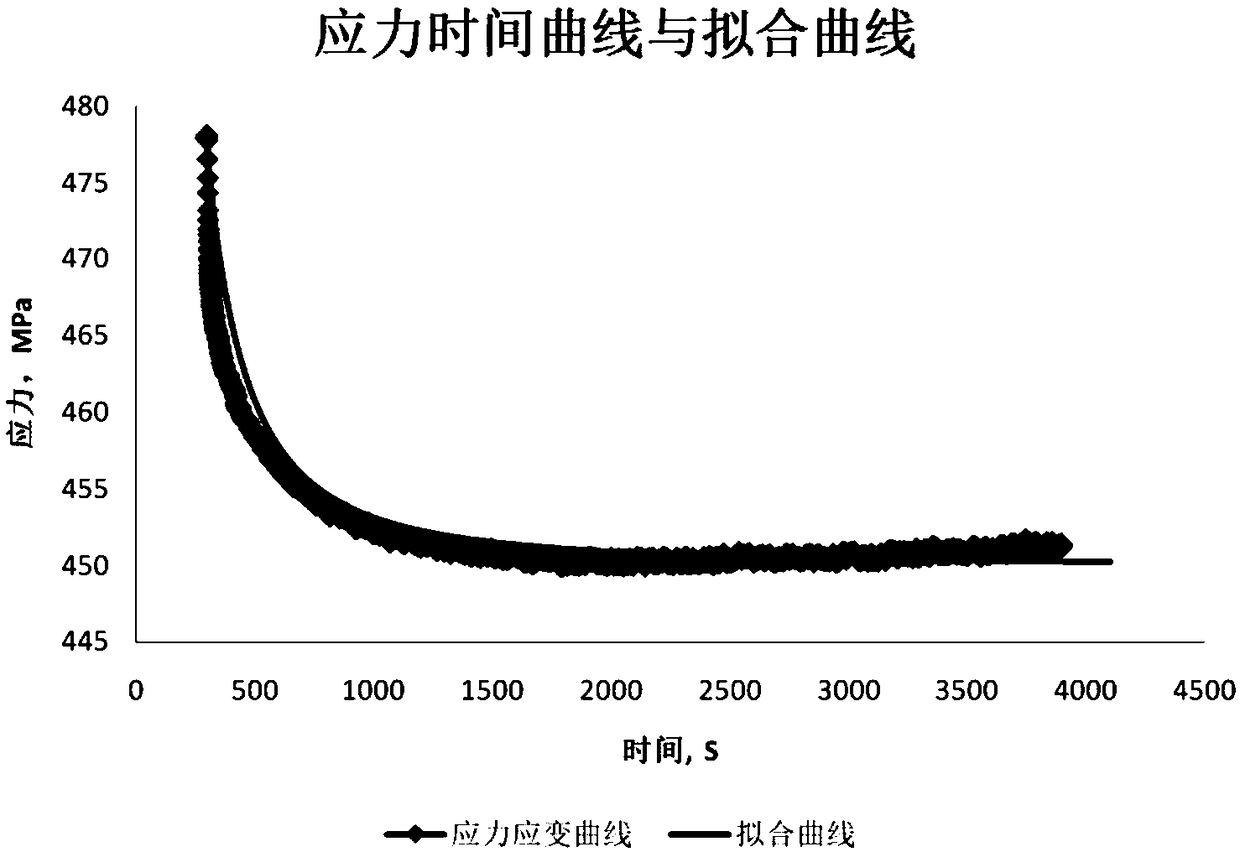

[0054] Such as Figure 4 is the true stress-strain curve of the tensile sample at a strain of 1.5%, using the formula σ 真实 = σ 最终 +a*exp(-t / b)+c*exp(-t / d) performs data fitting on the real stress-strain data obtained from the test, and the following results are obtained:

[0055] σ 最终 =461.76, a=-548.89, b=671.92, c=8653.88, d=671.81

[0056] σ 真实 =461.76-548.89*exp(-t / 671.92)+8653.88*exp(-t / 671.81)

[0057] Fitting curves such as Figure 4 As shown, according to the formula obtained from the fitting solution in the previous step, the time t is brought into infinity, and the obtained

[0058] σ s = σ 最终 =464.76MPa

Embodiment 2

[0060] Such as Figure 5 is the true stress-strain curve of the tensile sample at a strain of 3.5%, using the formula σ 真实 = σ 最终 +a*exp(-t / b)+c*exp(-t / d) performs data fitting on the real stress-strain data obtained from the test, and the following results are obtained:

[0061] σ 最终 =552.36, a=1.01e 5 , b=1015.81, c=8.92e 78 , d=51.91

[0062] σ 真实 =552.36+1.01e 5 *exp(-t / 1015.81)+8.92e 78 *exp(-t / 51.91)

[0063] Fitting curves such as Figure 4 As shown, according to the formula obtained from the fitting solution in the previous step, the time t is brought into infinity, and the obtained

[0064] σ s = σ 最终 =552.36MPa

Embodiment 3

[0066] Such as Image 6 is the true stress-strain curve of the tensile sample at 5.5% strain, using the formula σ 真实 = σ 最终 +a*exp(-t / b)+c*exp(-t / d) performs data fitting on the real stress-strain data obtained from the test, and the following results are obtained:

[0067] σ 最终 =618.91, a=1.75e 5 , b=1492.81, c=3.12e 29 , d=215.55

[0068] σ 真实 =651.98+1.75e 5 *exp(-t / 1492.81)+3.12e 29 *exp(-t / 215.55)

[0069] Fitting curves such as Figure 4 As shown, according to the formula obtained from the fitting solution in the previous step, the time t is brought into infinity, and the obtained

[0070] σ s = σ 最终 =618.91MPa

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com