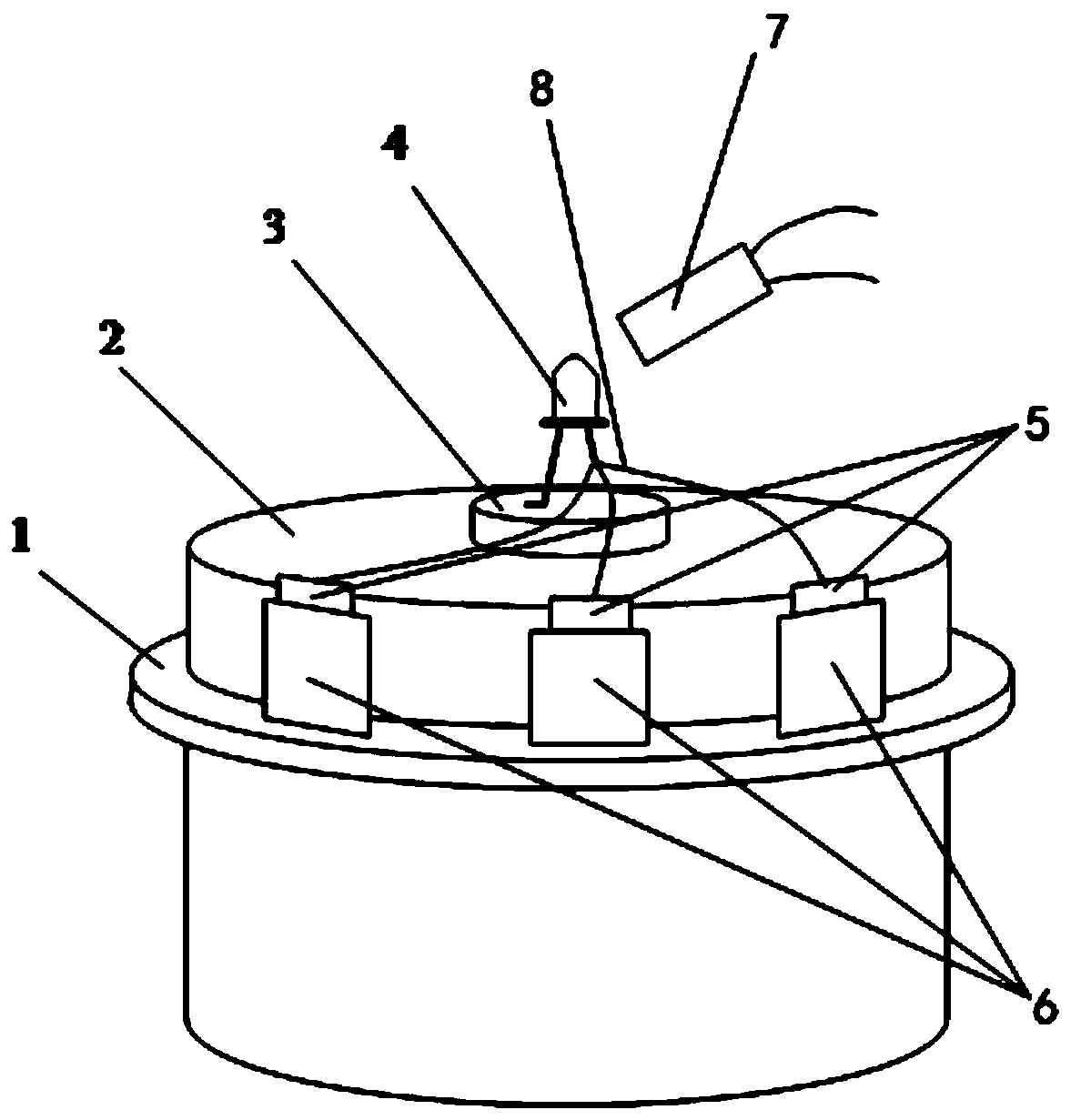

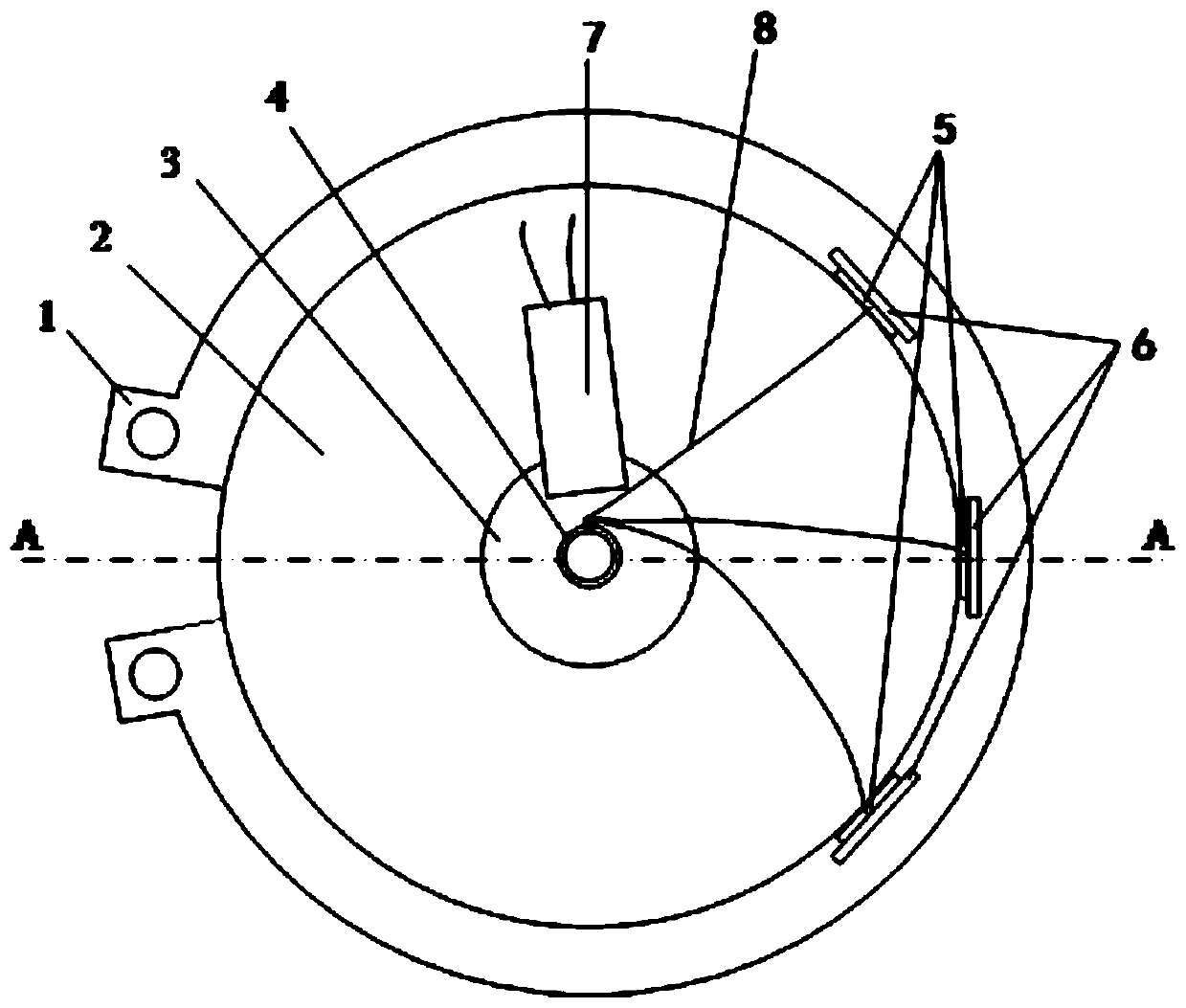

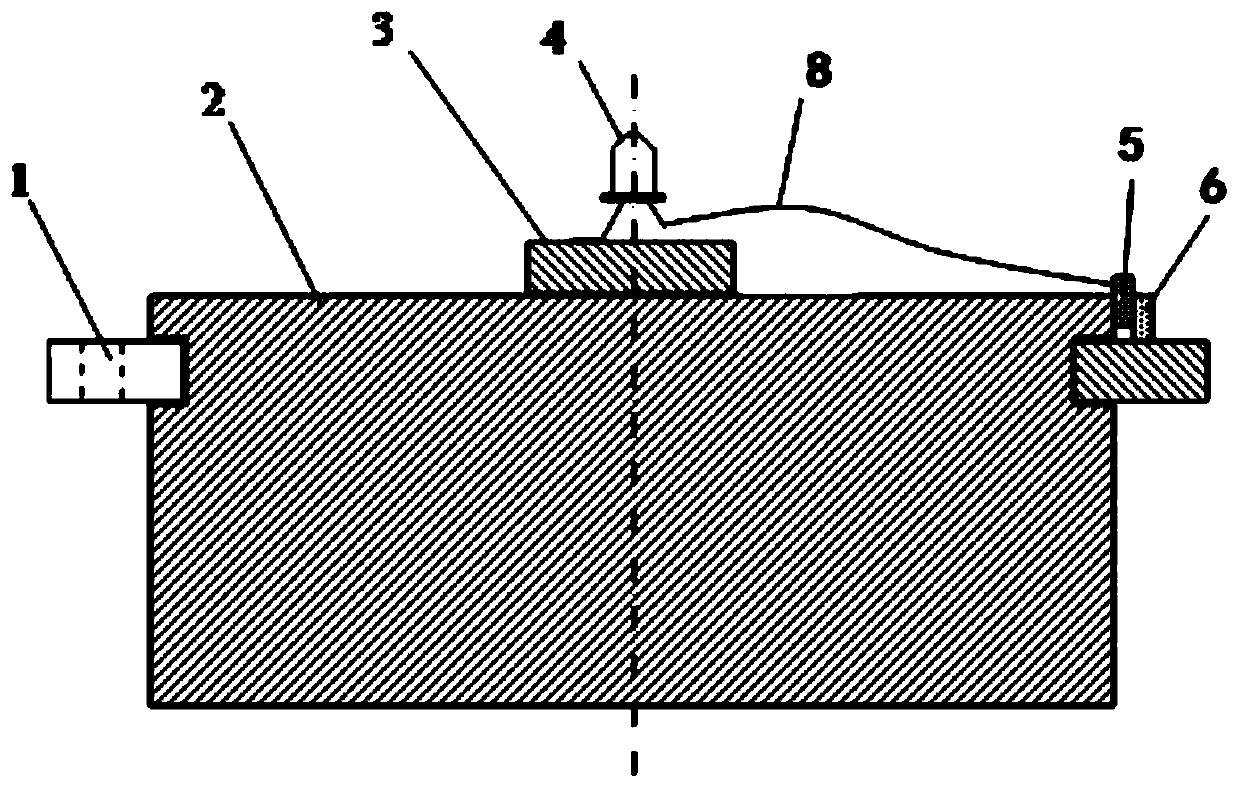

A contact state monitoring device between a shaft retaining ring and a shaft groove

A shaft retaining ring and contact state technology, which is applied in the field of contact state monitoring devices between the shaft retaining ring and the shaft groove, can solve the problems that it is difficult to monitor the contact state of the shaft retaining ring and the shaft groove, and achieve strong implementability and low occupation cost. The effect of small space and small quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] In this embodiment, based on the monitoring device for the contact state between the shaft retaining ring and the shaft groove in Embodiment 1, the monitoring experiment of the contact state between the Φ60mm and Φ100mm shaft retaining ring and the shaft groove is carried out.

[0044] When using the Φ60mm shaft retaining ring 1, install the Φ60mm shaft retaining ring 1 on the shaft 2 with a diameter of 60mm, the diameter of the shaft groove is 57mm, and then install the monitoring device on the shaft 2 and the shaft retaining ring 1. When the rotation speed of the shaft 2 reaches 7920RPM, the light-emitting diode 4 goes out, and the output switching value of the photosensitive module 7 jumps from low level to high level, indicating that the contact state between the shaft retaining ring 1 and the shaft groove changes, and the shaft retaining ring 1 and the Looseness occurs between shaft grooves. Reduce the shaft rotation speed again, and the contact state between the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com