One-way valve

A one-way valve, one-way technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of damaging the intake pipe valve, producing ash mixture, and not being able to rebound in time, so as to improve the rebound speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments shown in the drawings.

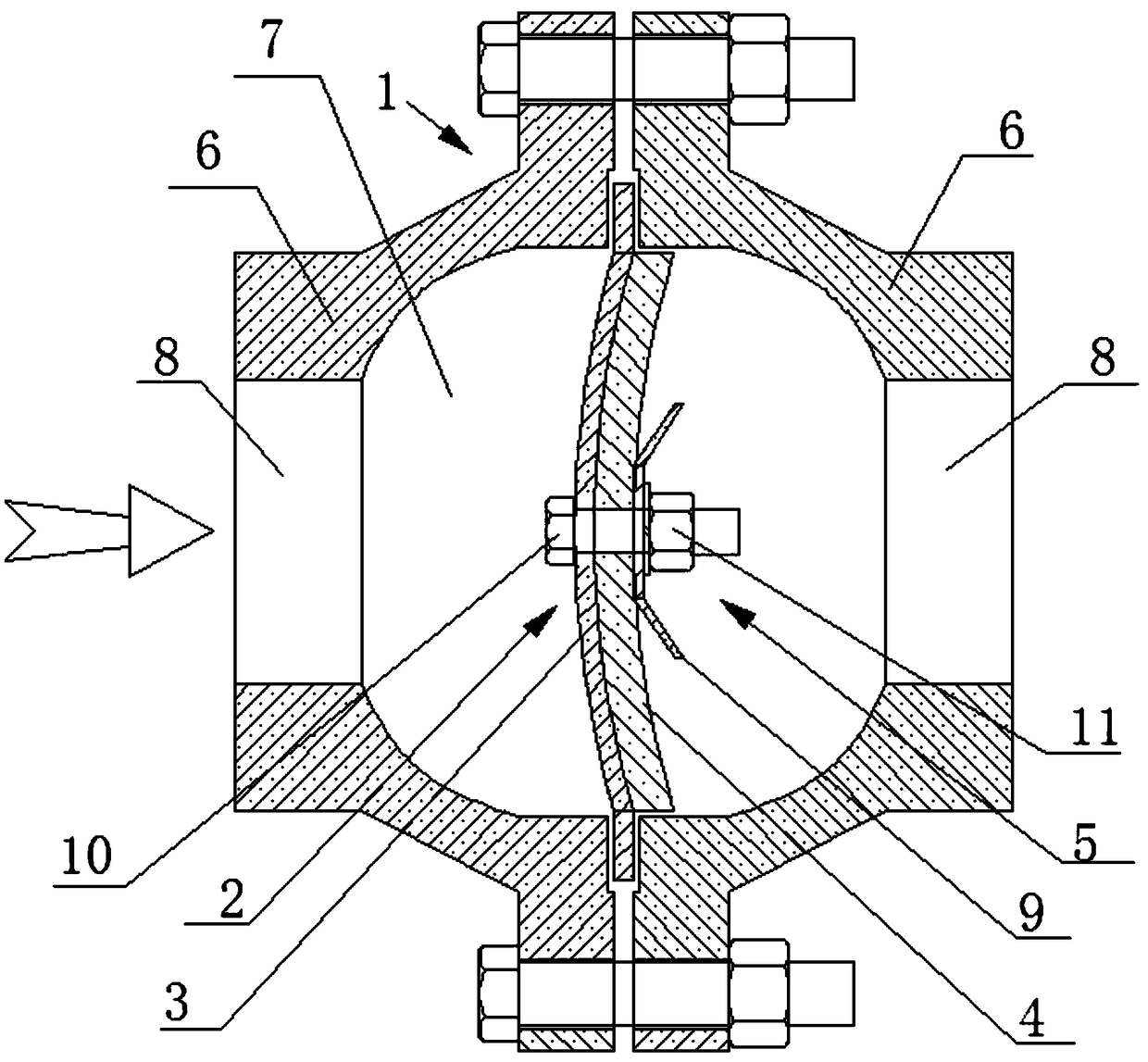

[0013] Such as figure 1 As shown, the one-way valve includes a valve body 1, a one-way bendable valve plate 2 installed in the valve body 1, and the valve plate 2 includes an air inlet orifice plate 3 tightly connected to the inner side wall of the valve body 1. , The rubber ring 4, which can be bent in one direction, is connected to the air inlet orifice plate 3. When no gas enters the valve body 1, the rubber ring 4 is closely attached to the valve body 1. 1 When the air inlet enters, a gap is formed between the bending of the rubber ring 4 and the valve body 1. The rubber ring 4 and the air inlet hole plate 3 are fixedly connected by a bolt assembly 5. The valve body 1 is composed of two symmetrical shells 6, and the joint surface of the two shells 6 is perpendicular to the axis of the valve body 1. The inner cavity of the valve body 1 is composed of a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com