Sock shaping system

A sock and setting machine technology, applied in the direction of setting/stretching ring fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of limited internal space, stacking of brackets, inconvenience, etc. The effect of styling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

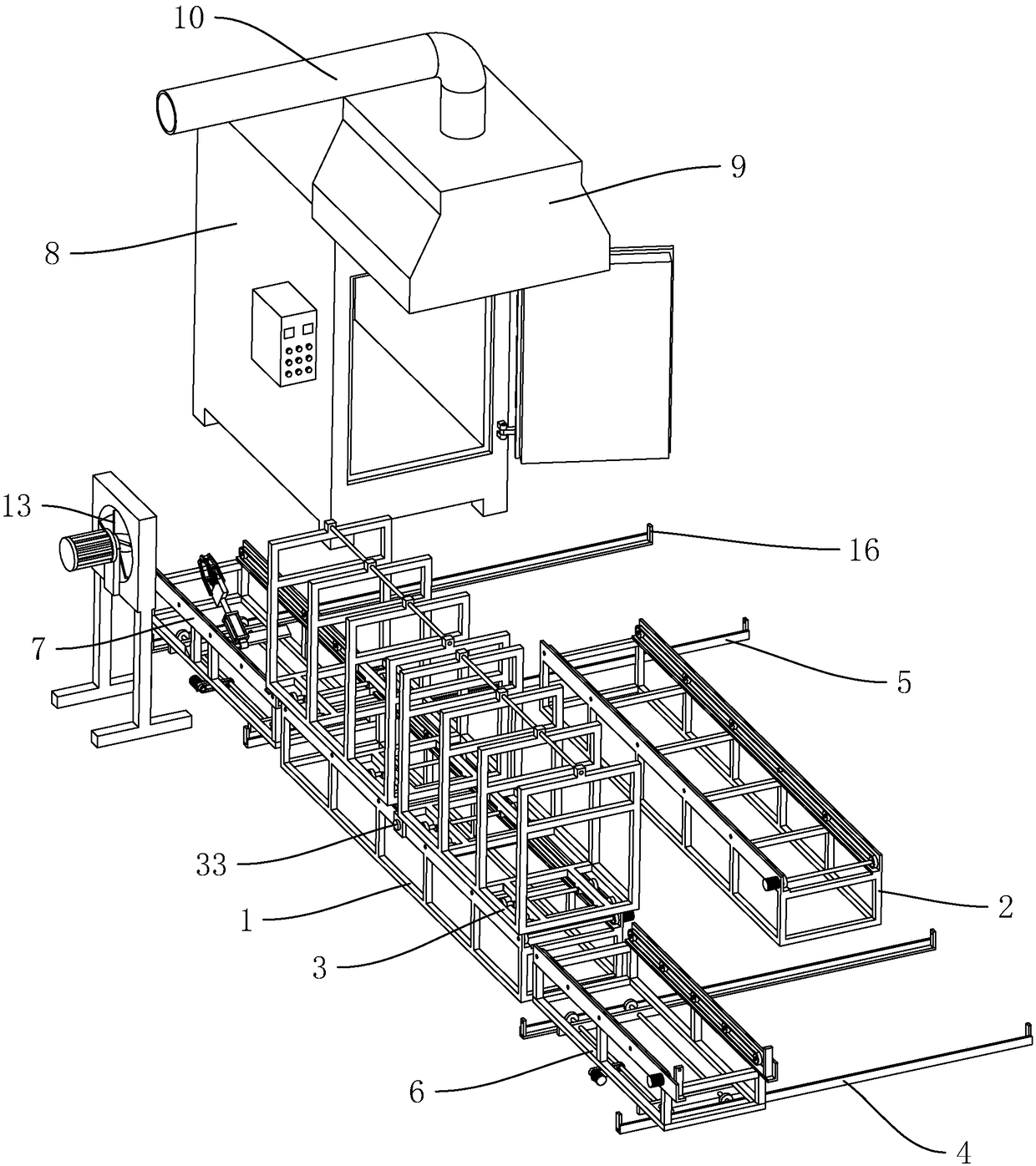

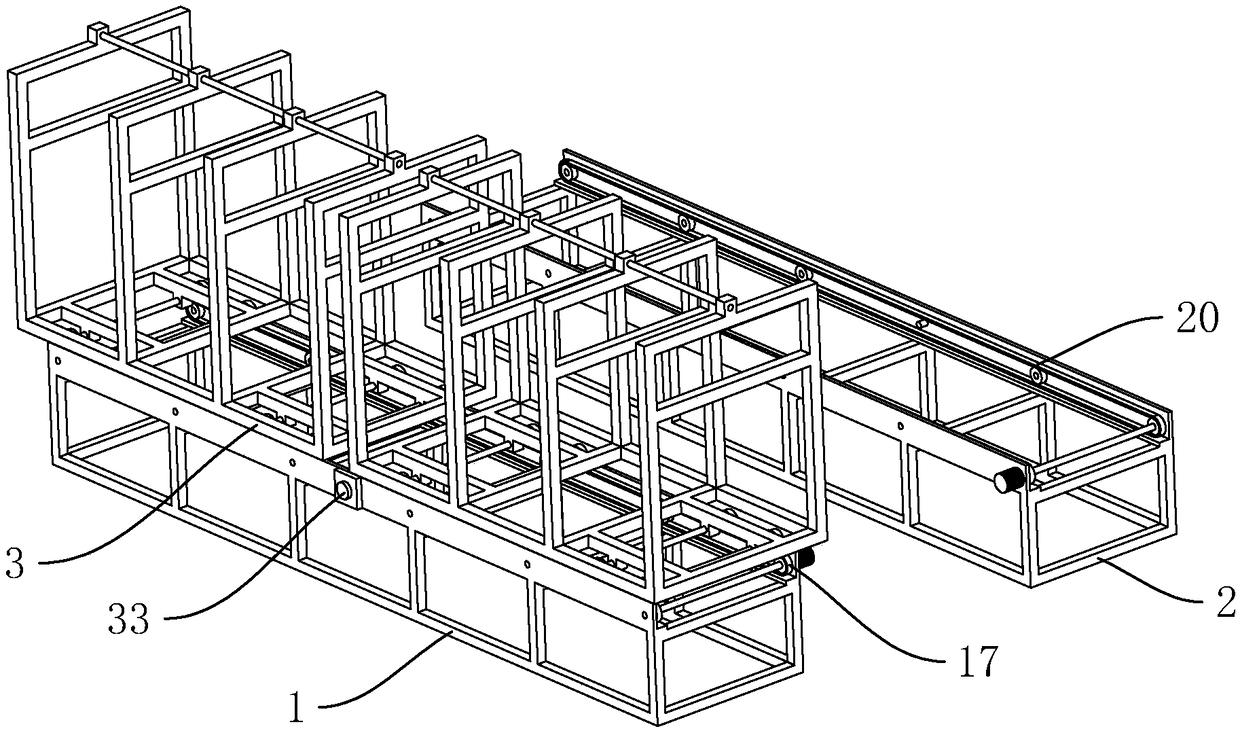

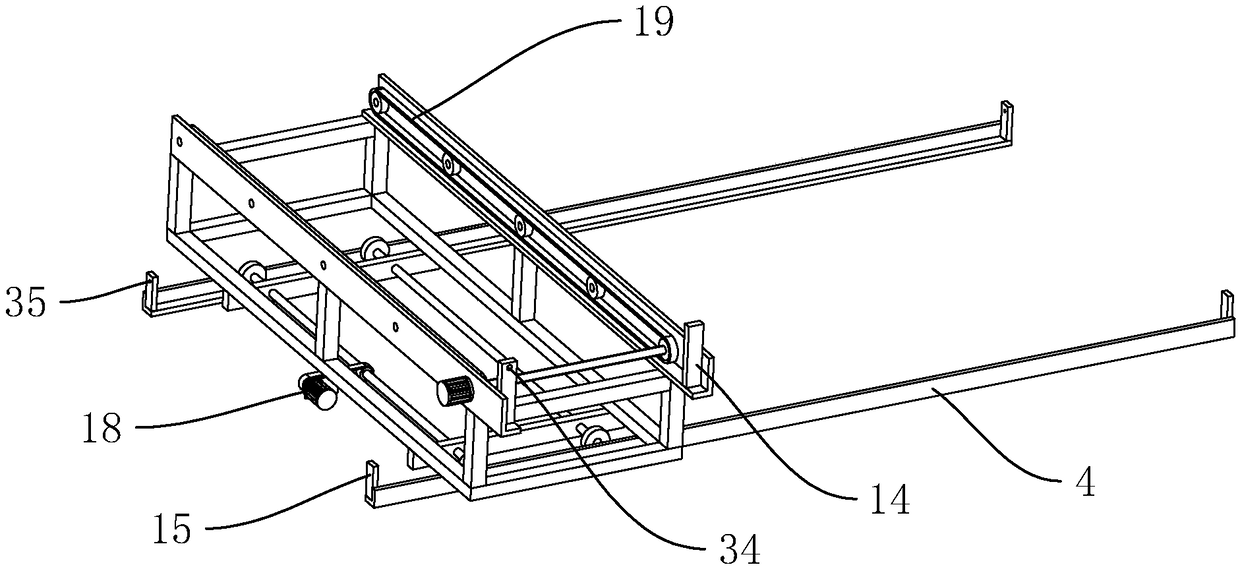

[0030] to combine figure 1 and figure 2 As shown, a sock setting system includes a first longitudinal rail 1 and a second longitudinal rail 2 of equal length and arranged side by side, the first longitudinal rail 1 and the second longitudinal rail 2 are arranged longitudinally, and the first longitudinal rail 1 is provided with There are a plurality of moving frames 3, and a plurality of rollers are arranged on the moving frames 3, so that the moving frames 3 can be conveniently moved along the first longitudinal rail 1. Also be provided with a control button 33 on the first vertical rail 1, and the left shift conveyor belt 17 that transmits to the left is provided on the first longitudinal rail 1, the roller of mobile frame 3 is supported on the left shift conveyor belt 17 and is subjected to the first vertical rail 1. Limit guide for rail 1. On the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com