Degreasing apparatus for industrial wastewater treatment

A technology for industrial waste water and waste water ponds, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problem of poor degreasing effect, adjusting the height of degreasing belt, and unable to adjust degreasing With problems such as falling height, to achieve the effect of convenient operation, good degreasing effect and best degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

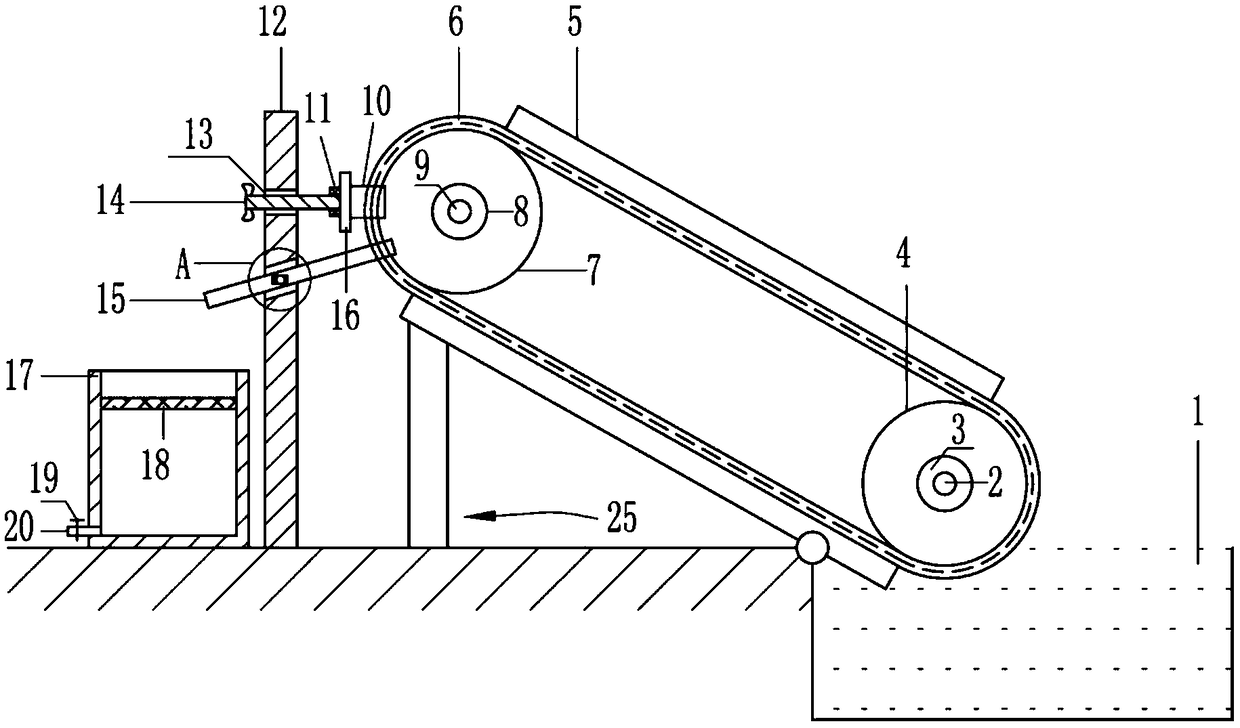

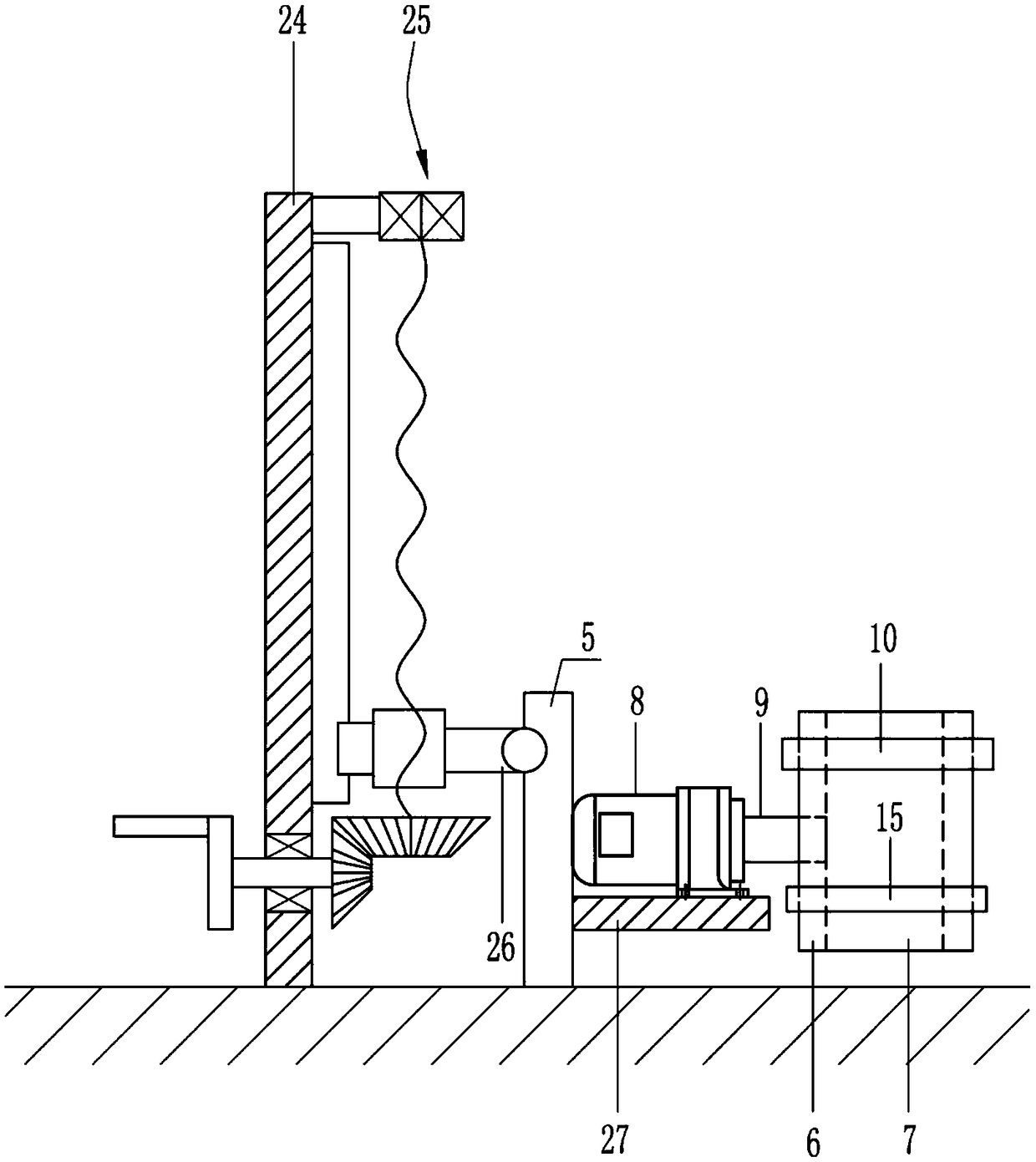

[0032] A degreasing device for industrial wastewater treatment, such as Figure 1-14As shown, it includes a waste water tank 1, a first rotating shaft 2, a first bearing seat 3, a first guide wheel 4, a lifting plate 5, an oil removal belt 6, a second guide wheel 7, a motor 8, a second rotating shaft 9, a scraper Sheet 10, second bearing seat 11, first mounting plate 12, first butterfly bolt 14, collecting bucket 15, connecting plate 16, collecting frame 17, mesh plate 18, valve 19, outlet pipe 20, second butterfly Bolt 23, second mounting plate 24, lifting mechanism 25, connecting rod 26 and third mounting plate 27; one end of lifting plate 5 is hinged with waste water pool 1; second mounting plate 24 is fixed on the ground along the vertical direction, and is positioned at The rear side of the plate 5; the lifting mechanism 25 is fixedly connected to the second mounting plate 24; one end of the connecting rod 26 is fixedly connected to the output end of the lifting mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com