Application of printing and dyeing sewage treatment equipment

A technology for processing equipment, printing and dyeing sewage, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. The effect of reducing waste, reducing pollution and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

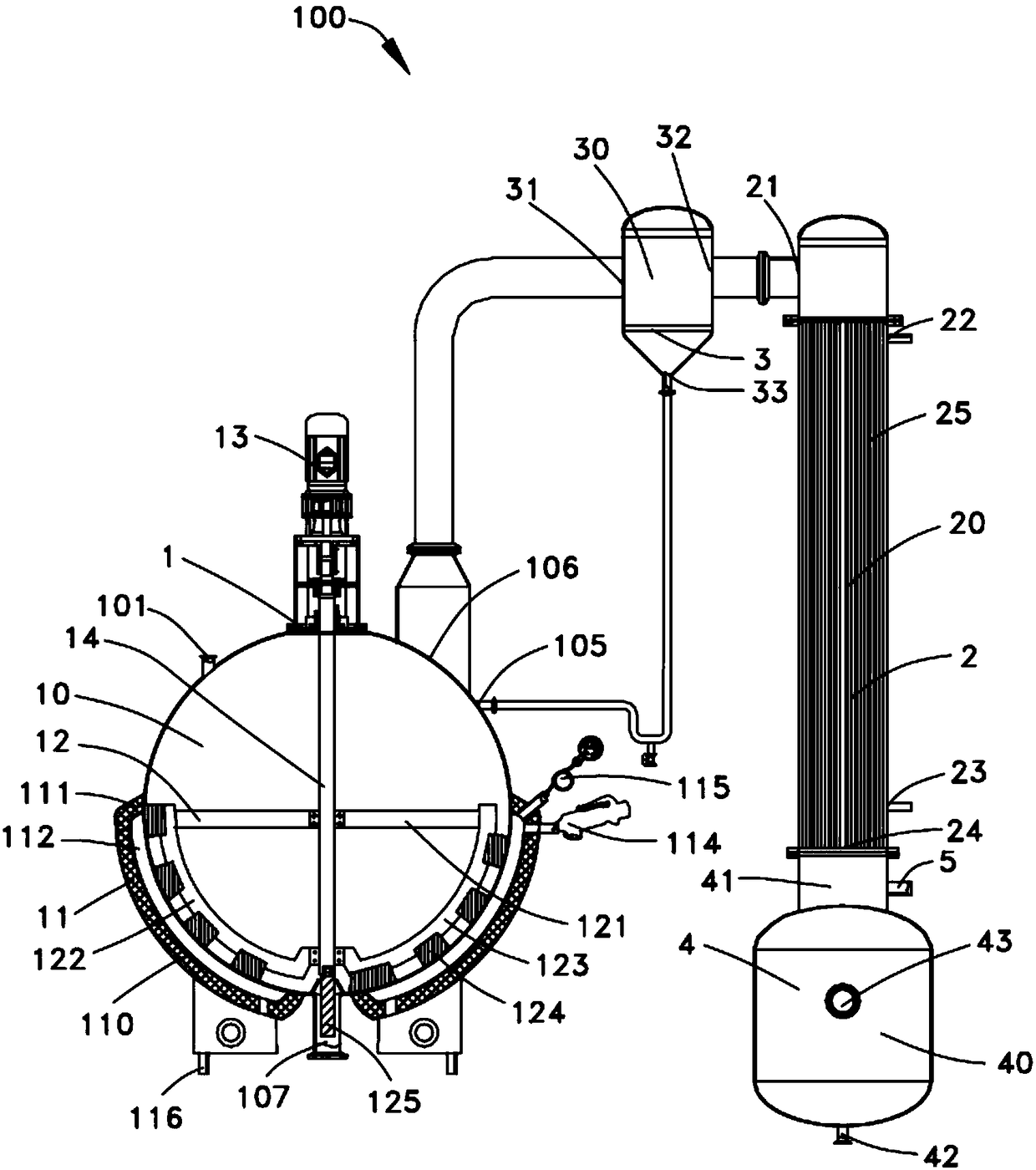

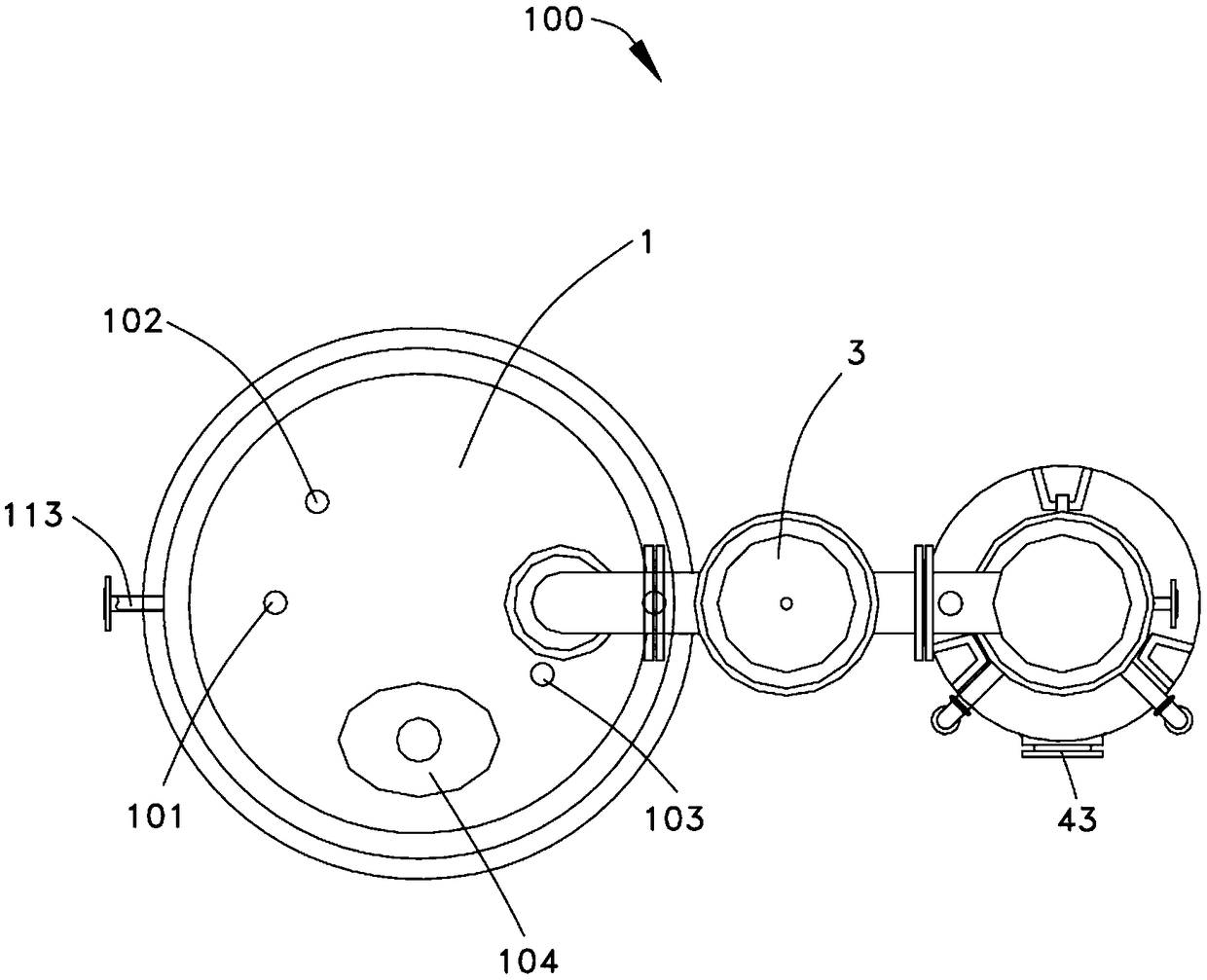

[0019] ginseng figure 1 As shown, the present invention discloses a printing and dyeing sewage treatment equipment 100, which is used to separate the ink and water from the sewage generated by printing and dyeing, which includes an evaporating device 1, a condensing device 2, connected between the evaporating device 1 and the condensing device 2 The vapor-liquid separation device 3 between them, the liquid collecting device 4 connected with the condensing device 2 and the vacuum pump 5 arranged between the condensing device 2 and the liquid collecting device 4 . In the following description, the direction perpendicular to the ground is taken as the up and down direction, and the end away from the ground is agreed to be the upper end. Space-related terms such as "upper", "lower", "top", "bottom", "middle", etc. can be used here Used to describe the positional relationship between components to simplify the description of the positional relationship between one component and ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com