Special lifting appliance for engine cylinder

A technology for engines and cylinders, which is applied in the field of special spreaders for engine cylinders, can solve problems such as insufficient safety, achieve the effect of not being easy to decouple and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

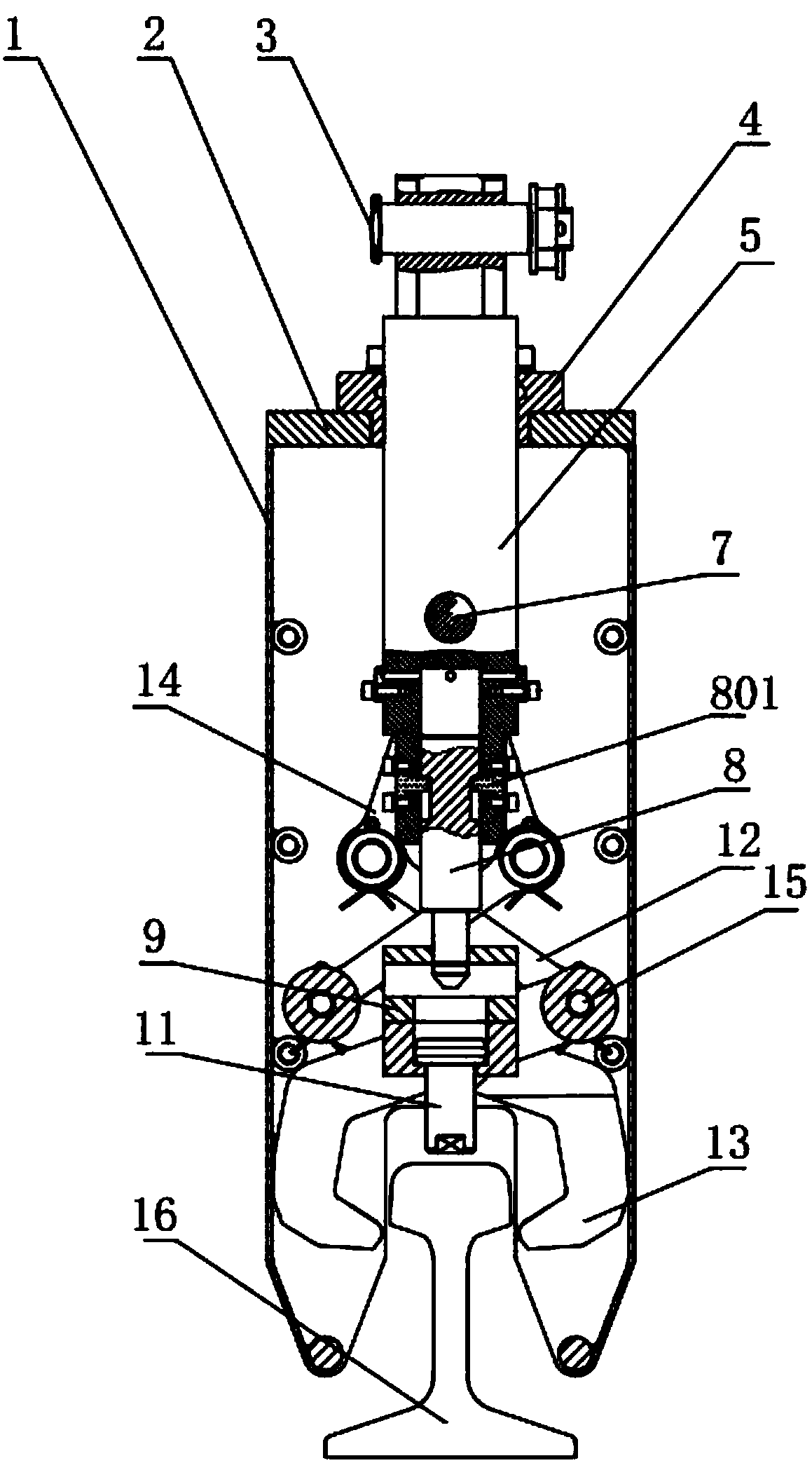

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] Such as figure 1 , 2 , Shown in 3,5, the outside of the present invention is casing, is made up of guide plate 6, casing side cover plate 1, casing upper cover plate 2. The upper part of the guide plate 6 is provided with a guide groove 601, and its bottom is designed with a V-shaped opening. Preferably, the included angle of the V-shaped opening is 45°.

[0029] Another example figure 1 , 2 , 3, the upper cover plate 2 of the box has a main shaft hole, the main shaft 5 is installed in the main shaft hole through the main shaft sleeve 4, the main body of the main shaft 5 extends into the inside of the box, and can The main shaft sleeve 4 is free to move. The upper part of the main shaft 5 is provided with an opening, and the guide shaft 7 is installed on the main shaft 5 through the opening. Both sides of the guide shaft 7 extend i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com