Lightweight fastening type opening mesh separator

A fastening type separator technology, which is applied in the field of main components, can solve the problems of complex structure, high production and operation costs, and high quality of the circular fixed disk of the separator, and achieve good fixing effect, long service life and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

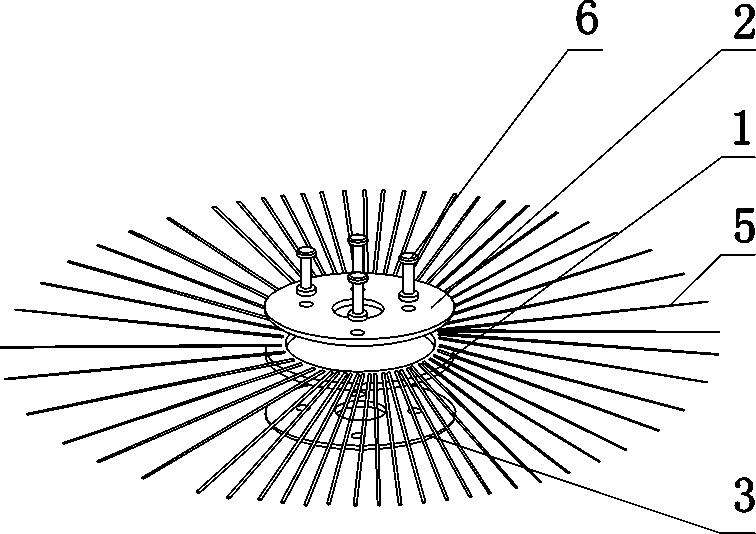

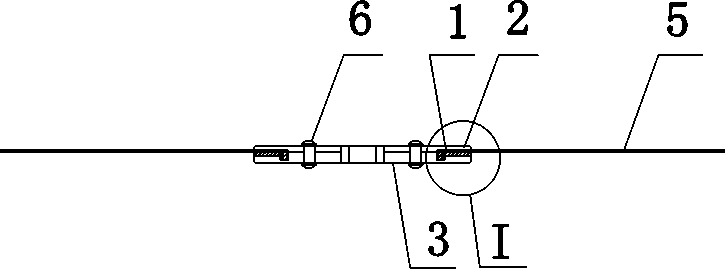

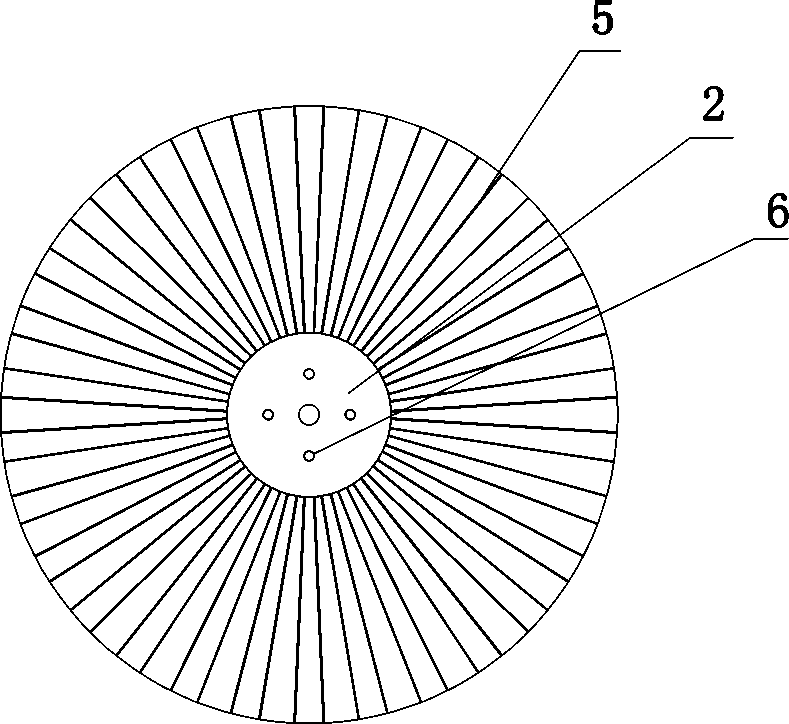

[0023] see Figure 1-7 , a light fastening type open mesh separator of the present embodiment has a circular fixed plate 1, and the top surface and the bottom surface of the circular fixed plate 1 are respectively provided with an upper gland 2 and a lower gland 3 , the circular fixed disk 1 is provided with a plurality of axial through holes 4 along the outer edge, every two through holes 4 form a group, and a U-shaped metal rod 5 is interspersed in each group of through holes 4, and the U-shaped metal rod 5 The two ends of the rod 5 penetrate through one end of a group of through holes 4 at the same time, and after passing through the bottom, they are bent to fit with the surface of the circular fixed disk 1 to form a radial network arrangement. The upper and lower glands 2 and 3 adopt The screw 6 is integrally connected with the circular fixed plate 1, wherein the upper gland 2 compresses and fixes the U-shaped metal rod 5.

[0024] In this embodiment, the U-shaped metal r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com