Fat pig breeding feed trough capable of automatically discharging materials and water by feeler lever

A technology of automatic feeding and touching of rods, which is applied in animal feeding devices, animal drinking devices, applications, etc., can solve the problems of slow manual action, low work efficiency, and large time gap, so as to improve the quality of breeding and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

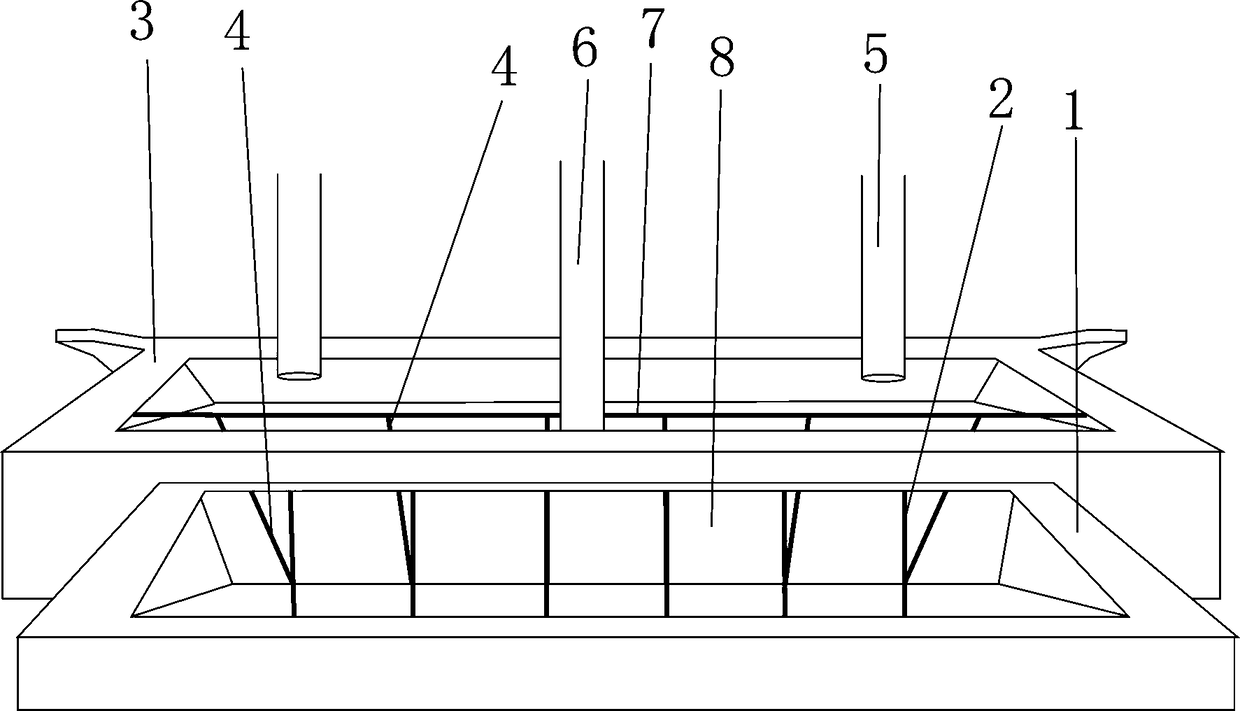

[0010] according to figure 1 As shown in the present invention, the contact bar automatically feeds and feeds the feeding tank for feeding fat pigs. There are many railings 2 in the feeding tank 1. Between the two railings 2 is a feeding port 8 for a fat pig. The food tank 1 is connected behind Feeding trough 3, feeding chute 3 is provided with automatic water discharge pipe 5, automatic feeding pipe 6, automatic feeding pipe 6 is connected with automatic feeding large contact rod 7, automatic feeding large contact rod 7 is connected with some automatic feeding small contact rods 4. The end of the automatic feeding small touch rod 4 is close to the partition rail 2, and the sources of the automatic feeding pipe 5 and the automatic feeding pipe 6 are connected to the automatic water source and the automatic feeding equipment.

[0011] How to use: After the automatic water source and automatic feeding equipment are started, the edible water and dry feed will automatically enter ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap