Quadruple heat exchange system for energy conservation, emission reduction and white smoke elimination of flue gases

A technology for energy saving, emission reduction, and heat exchange system, which is applied to heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of unsatisfactory tail gas de-whitening effect, low desulfurization efficiency, and large water consumption, etc., to achieve Improve the effect of treatment, reduce the temperature of flue gas, and reduce the effect of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

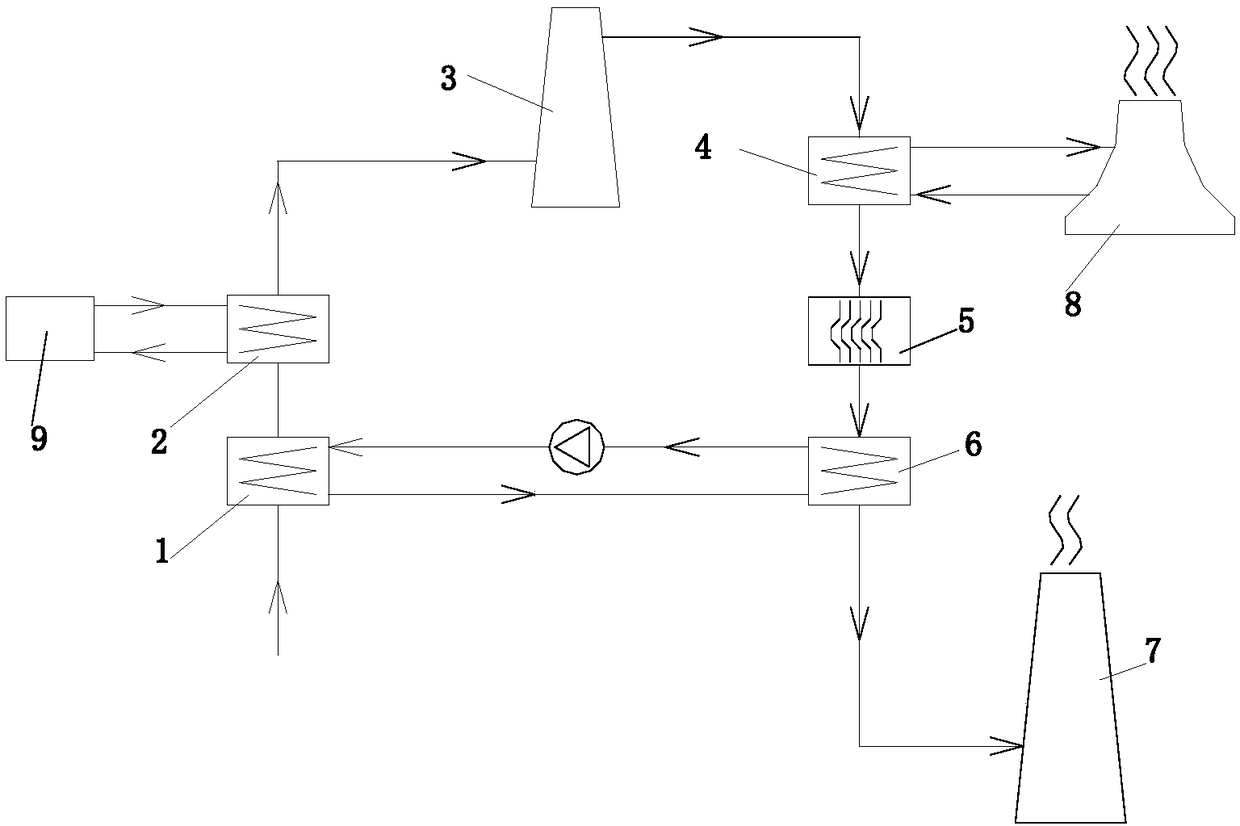

[0019] Example. A quadruple heat exchange system for flue gas energy saving, emission reduction and white elimination, which is composed of Figure 1 to Figure 5 As shown, it includes a front flue gas cooler 1, a water and flue gas heat exchanger 2, a desulfurization tower 3, a condenser 4, a demister 5, a rear flue gas reheater 6 and a chimney 7 connected in sequence; The condenser 4 is connected to a cooling tower 8 through a circulation pipeline; the front flue gas cooler 1 and the rear flue gas reheater 6 are connected through a circulation pipeline.

[0020] The water and flue gas heat exchanger 2 is connected to a desalinated water tank 9 through a circulation pipeline.

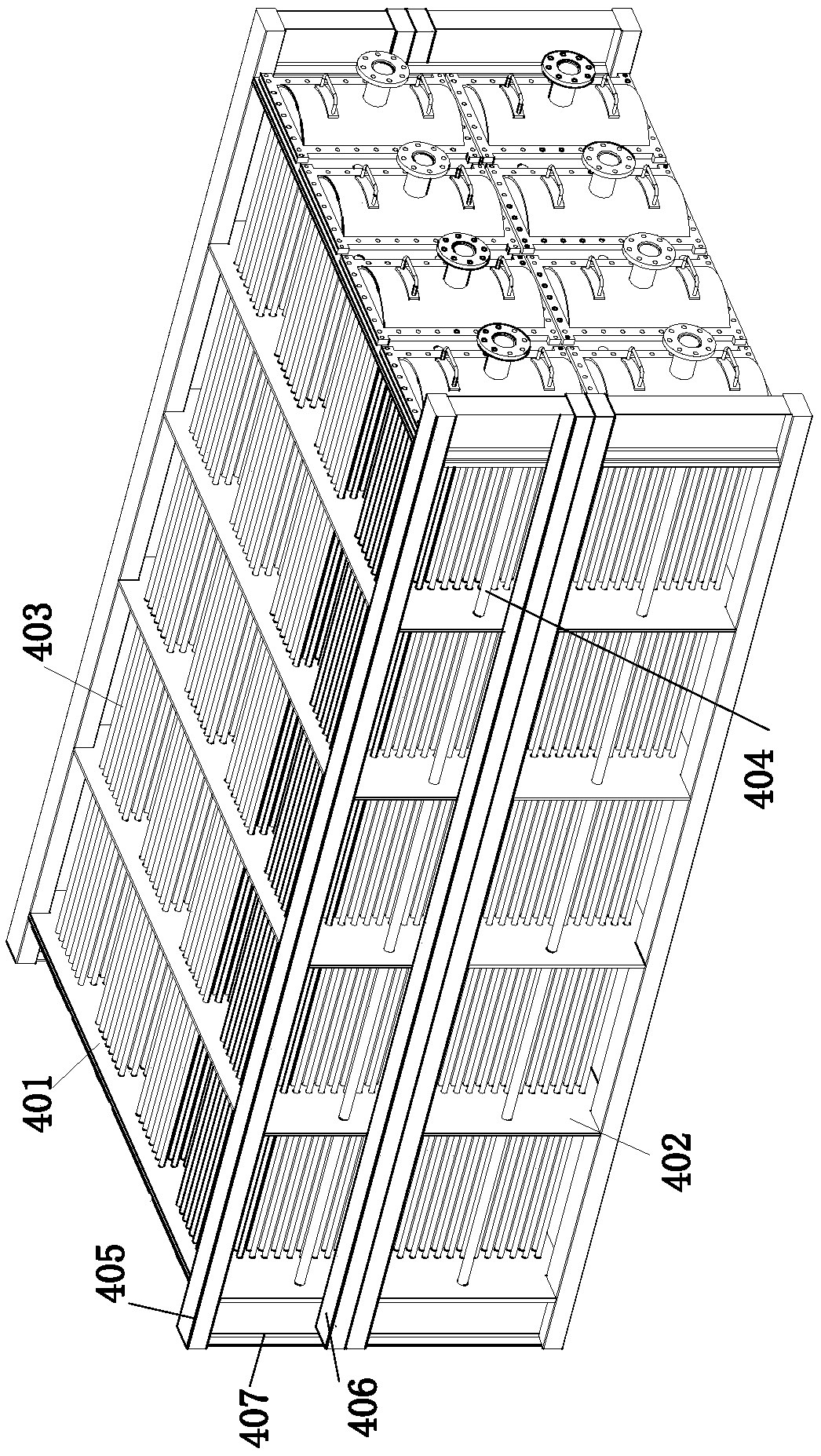

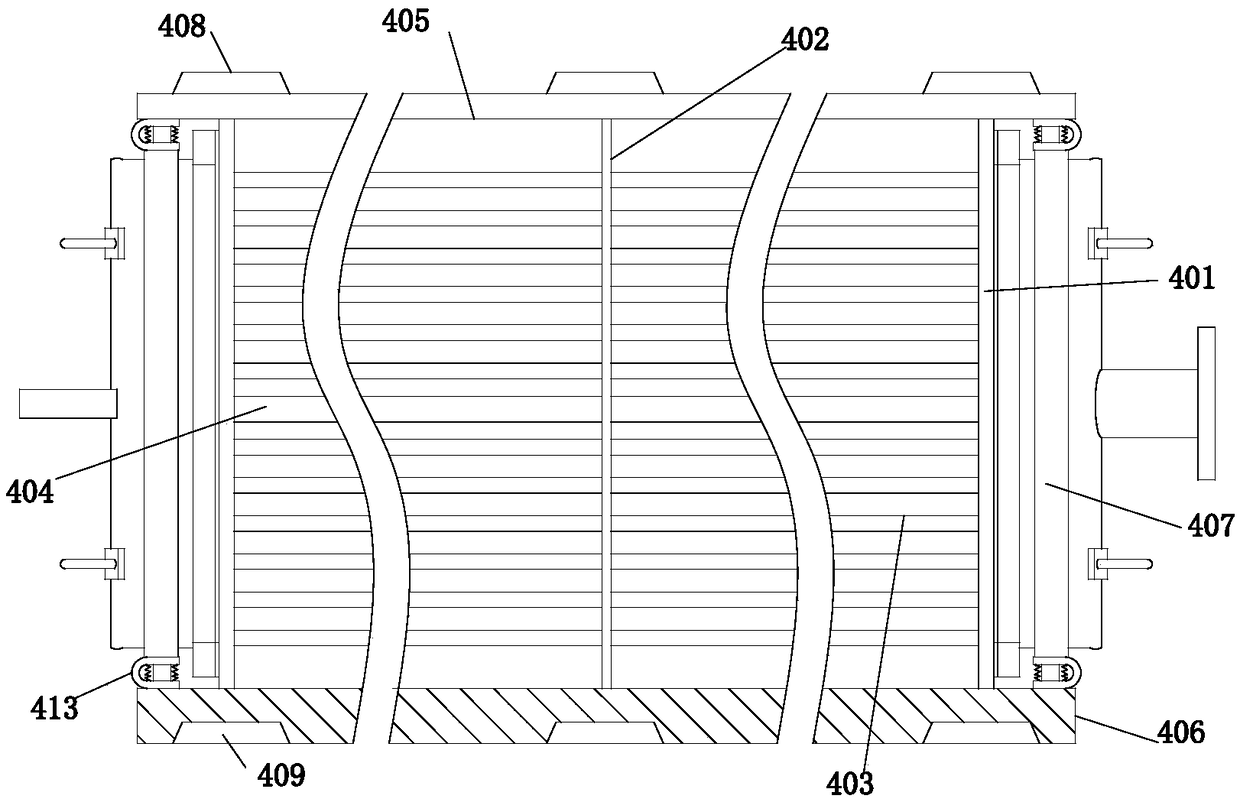

[0021] The condenser 4 includes a plurality of heat exchanger modules stacked up and down; the heat exchanger module incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com