An easy-to-align parts installation machine

A part installation and installation machine technology, applied in metal processing machinery parts, feeding devices, manufacturing tools, etc., can solve the problems of inaccurate positioning, time-consuming manual installation, worker fatigue, etc., to increase accuracy and convenience. performance, improve operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

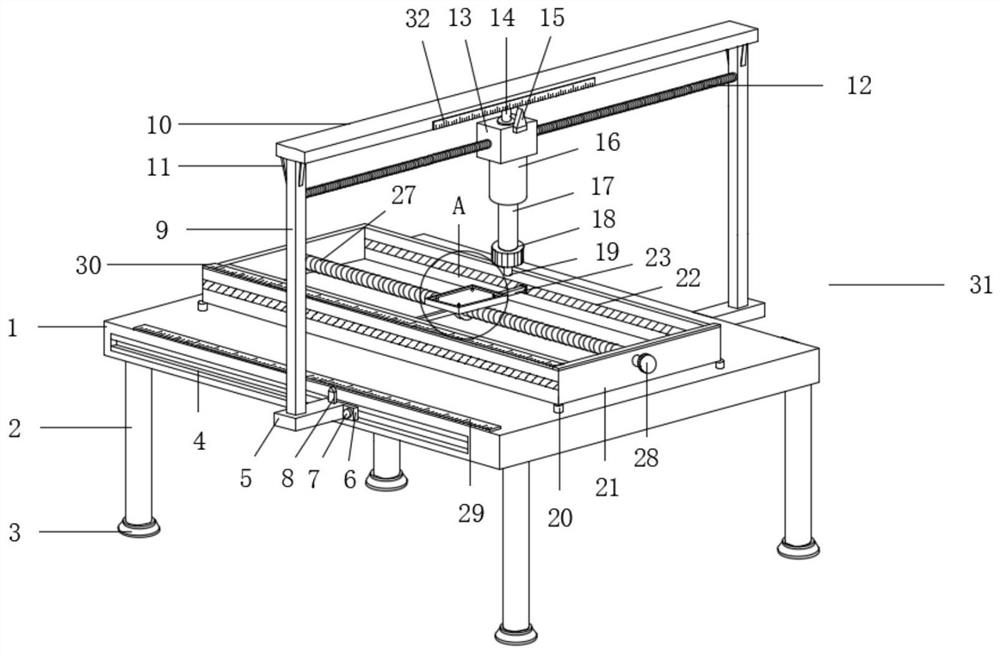

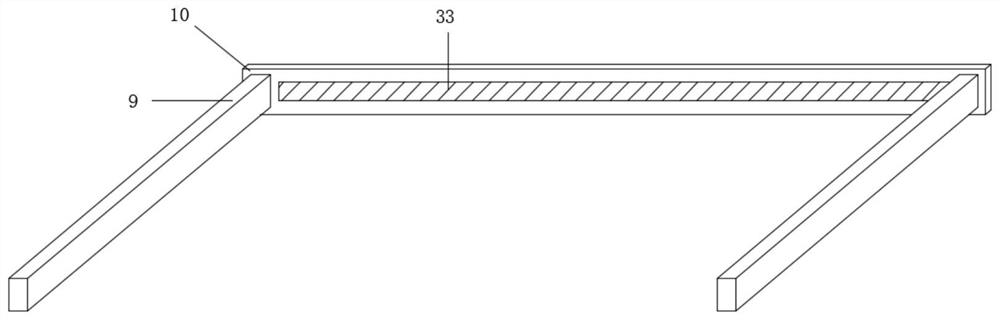

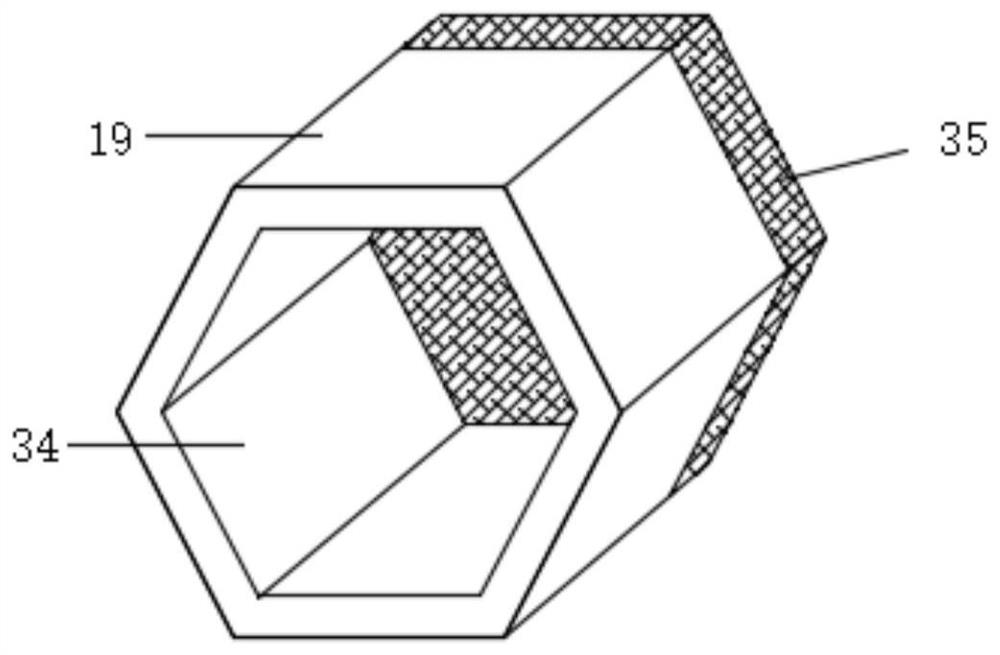

[0020] like Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a machine for mounting parts convenient for alignment, including a part mounting work surface 1, a screw motor 13 and a device body 31, and several fixed supports are uniformly arranged around the bottom of the device body 31 Leg mounting base 3, the upper ends of the fixed leg mounting base 3 are fixedly connected to the work surface fixed leg 2, and the end of the work surface fixed leg 2 away from the fixed leg mounting base 3 is fixedly connected to the part installation work surface 1. No. 1 side chute 4 is provided on both sides of the part installation work surface 1, and a side chute slider is provided inside the No. 1 side chute 4, and the No. 1 side chute 4 passes through the side chute The slide block is slidably connected with a chute support plate 5, and the chute support plate 5 can move freely on the No. 1 side body chute 4, and one side of the chute support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com