Multi-shaft-hole automatic aligning method based on laser tracker

A laser tracker and shaft hole technology, which is used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the research on multi-axis hole alignment of large parts and components has not been published, and the automatic assembly of large parts is still in the research stage , has not yet been practical and other problems, to achieve the effect of high-precision automatic alignment, stable and efficient assembly operations, and make up for the lack of absolute motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

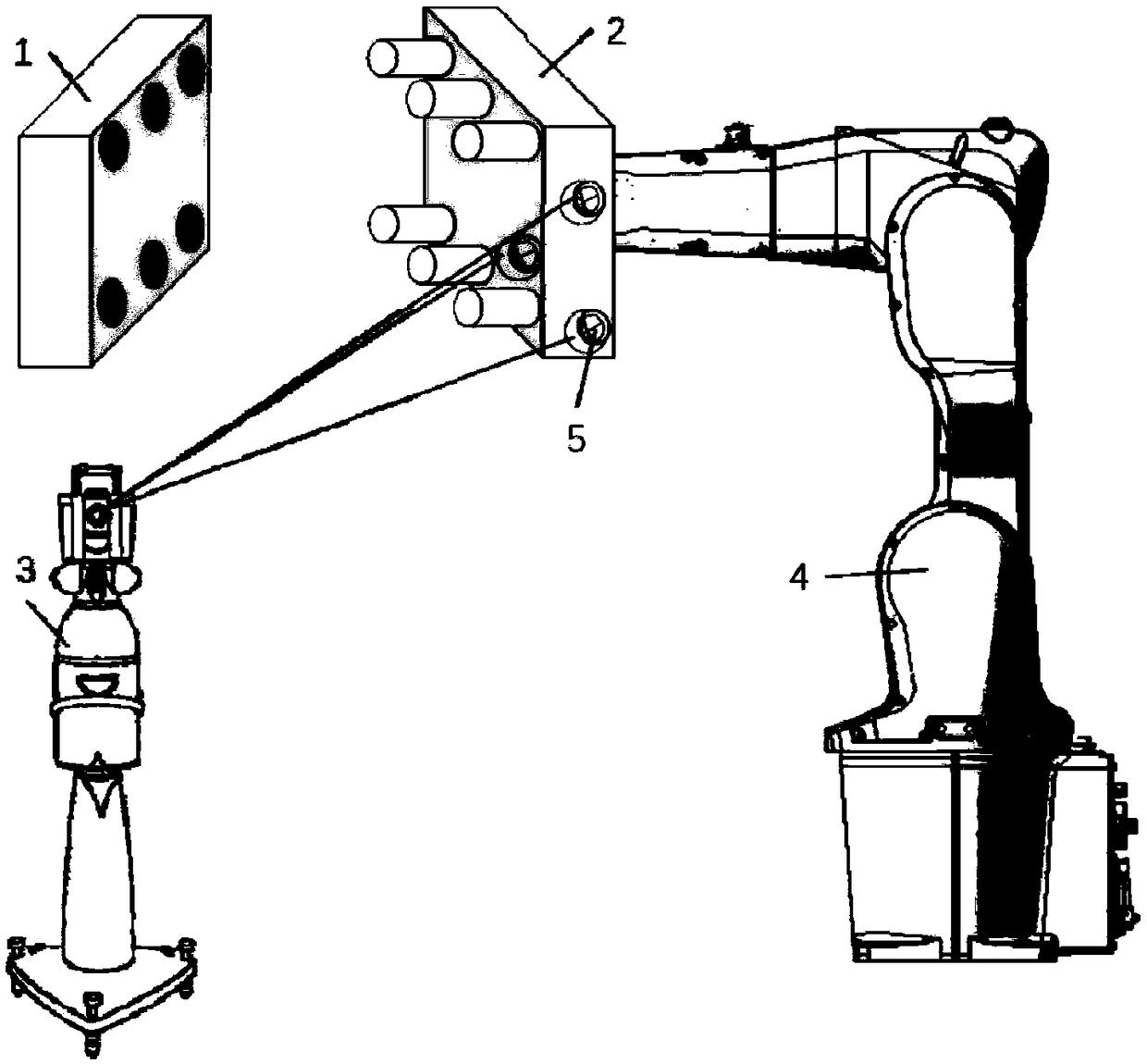

[0052] The present invention proposes an automatic alignment method for multi-axis holes based on a laser tracker. The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0053] The present invention proposes an automatic alignment method for multi-axis holes based on a laser tracker. The overall process is as follows figure 1 shown, including the following steps:

[0054] 1) Building an automatic multi-axis hole alignment system; the multi-axis hole automatic alignment system includes: a laser tracker, a mechanical arm and a computer. The laser tracker and the mechanical arm are respectively connected to the computer by wire or wirelessly. Among them, the laser tracker and the computer can be of any type, and the mechanical arm can be greater than six degrees of freedom.

[0055] The laser tracker is used in conjunction with a reflective target ball or a T-Prob to measure the parts with holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com