Automatically controlled ingredient weighing production line

A production line and weighing device technology, applied in the direction of non-electric variable control, program control, sequence/logic controller program control, etc., can solve the problems of large error, low efficiency, unstable weighing effect, etc., to achieve Realize data-based management, improve accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

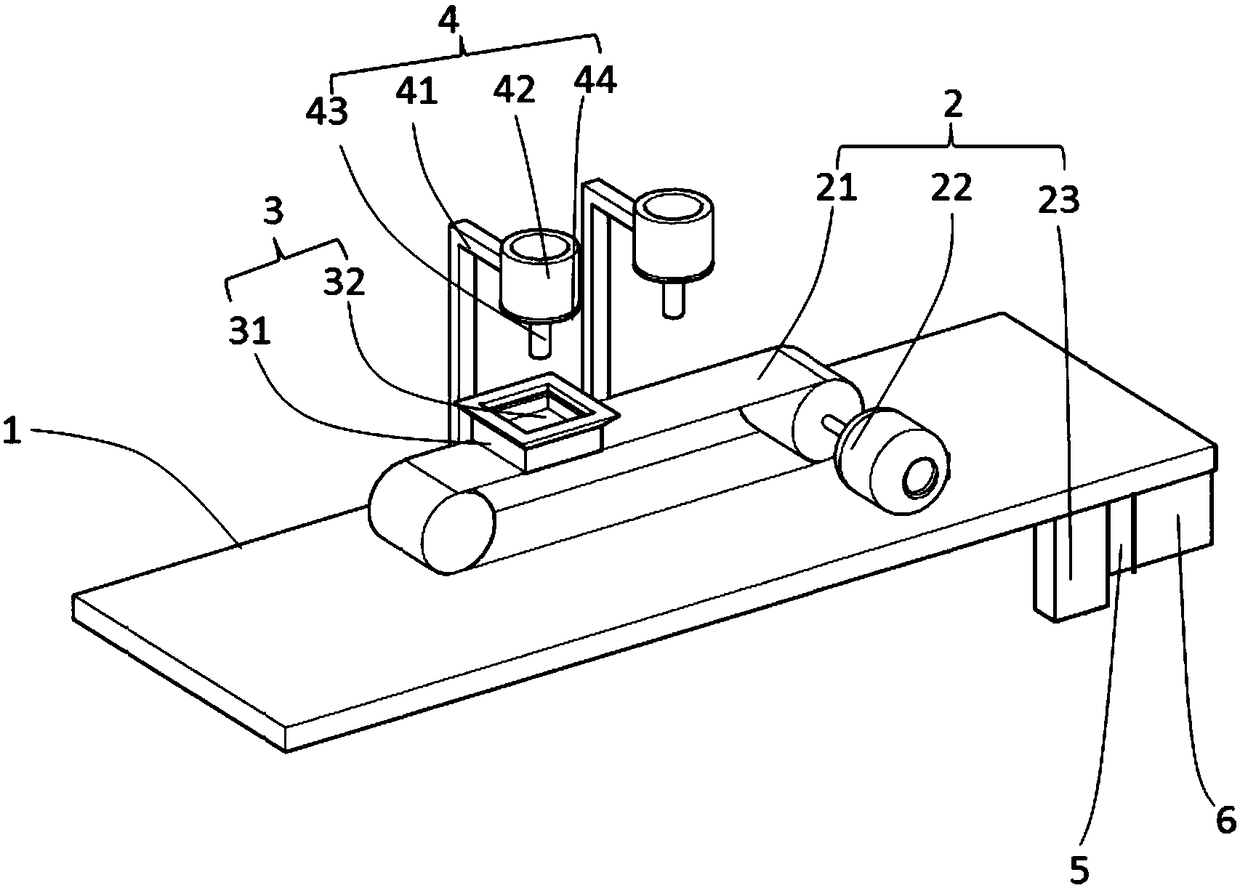

[0015] Embodiment 1: refer to Figure 1-3 , an automatically controlled batching and weighing production line, including a workbench 1, a conveying device 2, a weighing device 3, at least two feeding devices 4, a programmable controller 5, and a control panel 6;

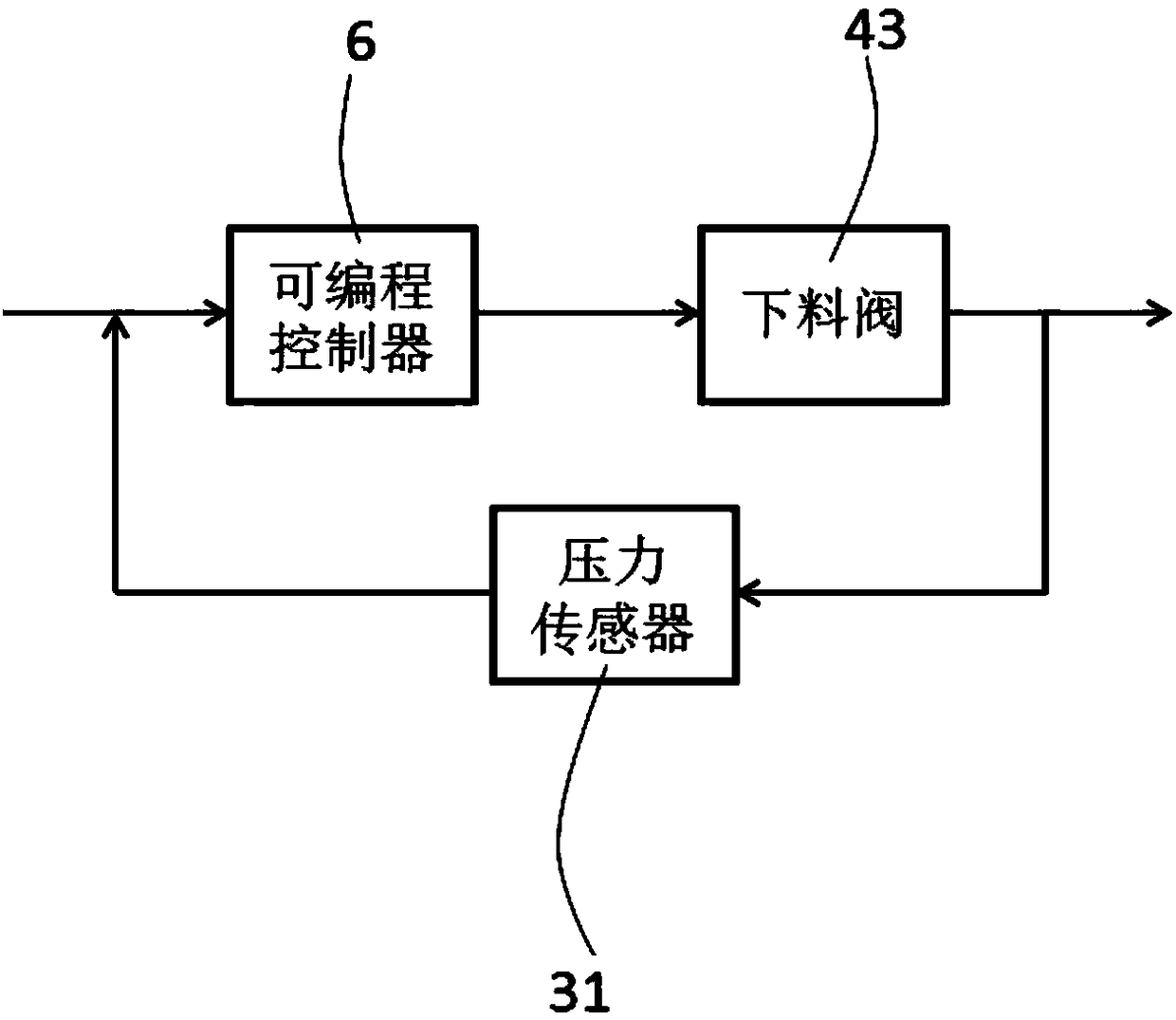

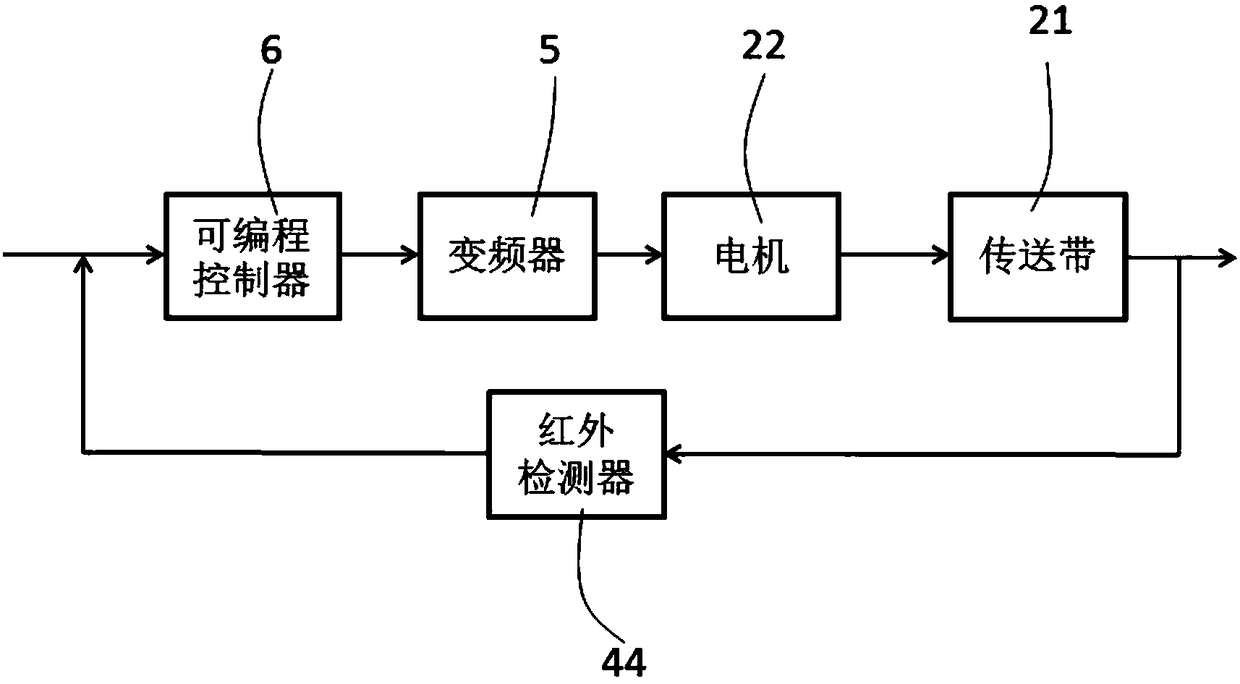

[0016] Conveying device 2, weighing device 3, unloading device 4, programmable controller 5, control panel 6 are fixed on the workbench 1, and conveying device 2 comprises conveyor belt 21, motor 22 and frequency converter 23, and weighing device 3 comprises scale The feeding cart 32 and the pressure sensor 31 , the feeding device 4 includes a bracket 41 , a feeding tank 42 , a feeding valve 43 and an infrared position detector 44 .

[0017] The weighing device 3 is arranged on the conveyor belt, the conveyor belt 21 is connected to the motor 22, the motor 22 is electrically connected to the frequency converter 23, the frequency converter 23 is electrically connected to the analog output interface of the programmable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com