LED packaging glue anti-sedimentation storage device

A technology for LED packaging and storage devices, which is used in transportation and packaging, mixer accessories, mixers, etc., which can solve the problem of easy glue leakage at the assembly of the stirring impeller, easy precipitation and even curing of LED glue, and limitations of applicability and practicability, etc. problems, to achieve the effect of good use stability, reasonable structure setting and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

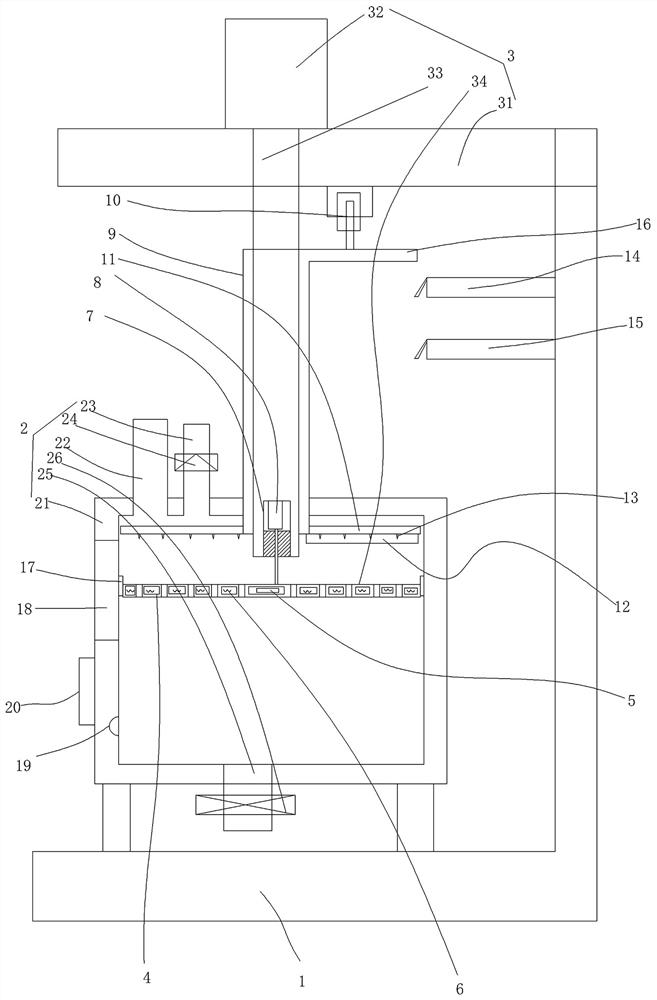

[0016] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0017] See figure 1 , an LED packaging glue anti-sedimentation storage device, including a base 1, a storage structure 2 arranged on the base 1 and an anti-sedimentation structure 3 arranged on the storage structure 2, the storage structure 2 includes a storage box 21 A liquid inlet channel 22 and an exhaust channel 23 are arranged on the top of the storage box 21, a one-way air valve 24 is arranged in the exhaust channel 23, and a liquid outlet channel is arranged at the bottom of the storage box 21 25. A control valve 26 is provided on the liquid outlet channel 25, and the anti-sedimentation structure 3 includes a lifting bracket 31, and a lifting cylinder 32 is arranged on the lifting bracket 31, and at the center of the top wall of the storage box 21 A lifting hole 3 is provided, and a guide rod 33 is fixed on the piston shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com