Nb-containing ferritic stainless steel sheet and manufacturing method therefor

A manufacturing method, stainless steel technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as lack of teaching, and achieve the effect of improved swelling resistance and high press workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

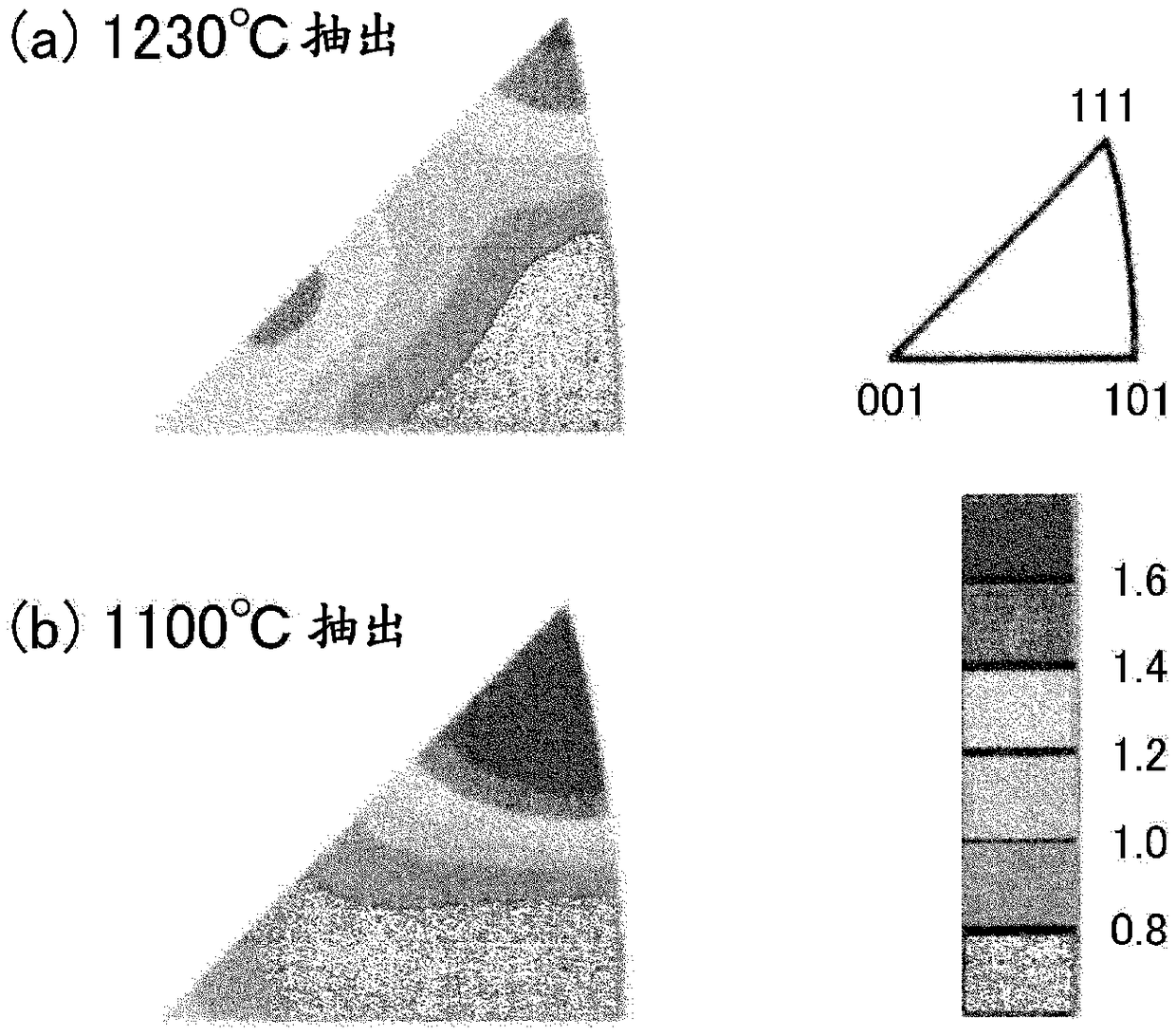

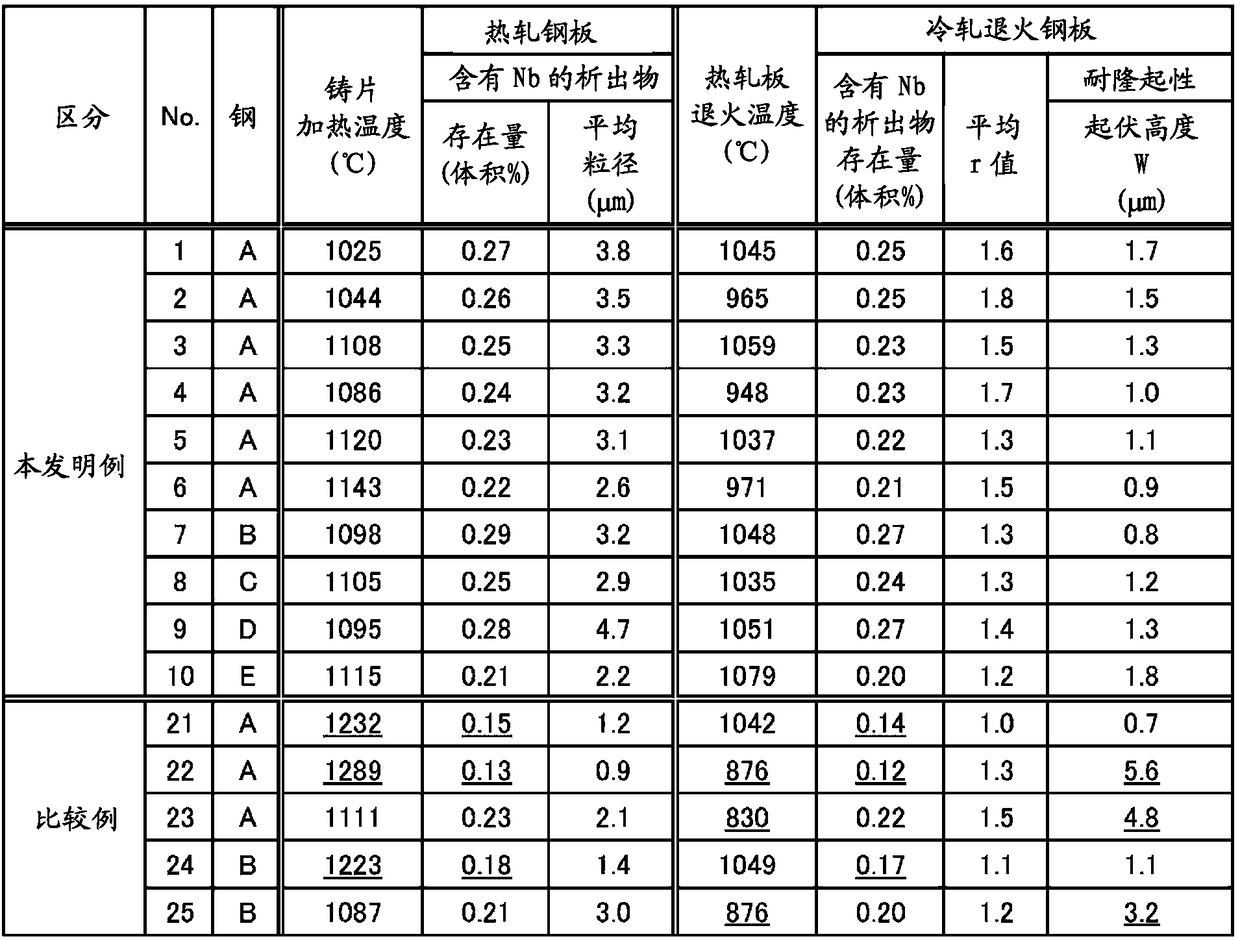

[0069] Steels having the chemical compositions shown in Table 1 were melted by a conventional method to obtain cast slabs (continuously cast slabs). Each slab was heated at the slab heating temperature shown in Table 2 for 120 minutes, extracted, and hot-rolled to form a hot-rolled steel sheet with a thickness of 4.5 mm. The rolling temperature in the final pass of hot rolling is 650 to 700°C, and the coiling temperature is in the range of 500 to 650°C.

[0070] [Table 1]

[0071] Table 1

[0072]

[0073] Samples were taken from each hot-rolled steel sheet, and the amount of Nb-containing precipitates was determined by the electrolytic extraction method according to the above-mentioned "Method for determining the amount of Nb-containing precipitates". In addition, for each hot-rolled steel sheet, a cross-section (L cross-section) parallel to the rolling direction and the plate thickness direction was observed by SEM using Hitachi S-4000. "Precipitation method" to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com