Work machine and rice planting machine

A working machine and engine technology, which is applied in the direction of machines/engines, agriculture, transplanting machinery, etc., can solve the problems of low maintainability, obstruction of shielding parts, etc., and achieve the effect of improving maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

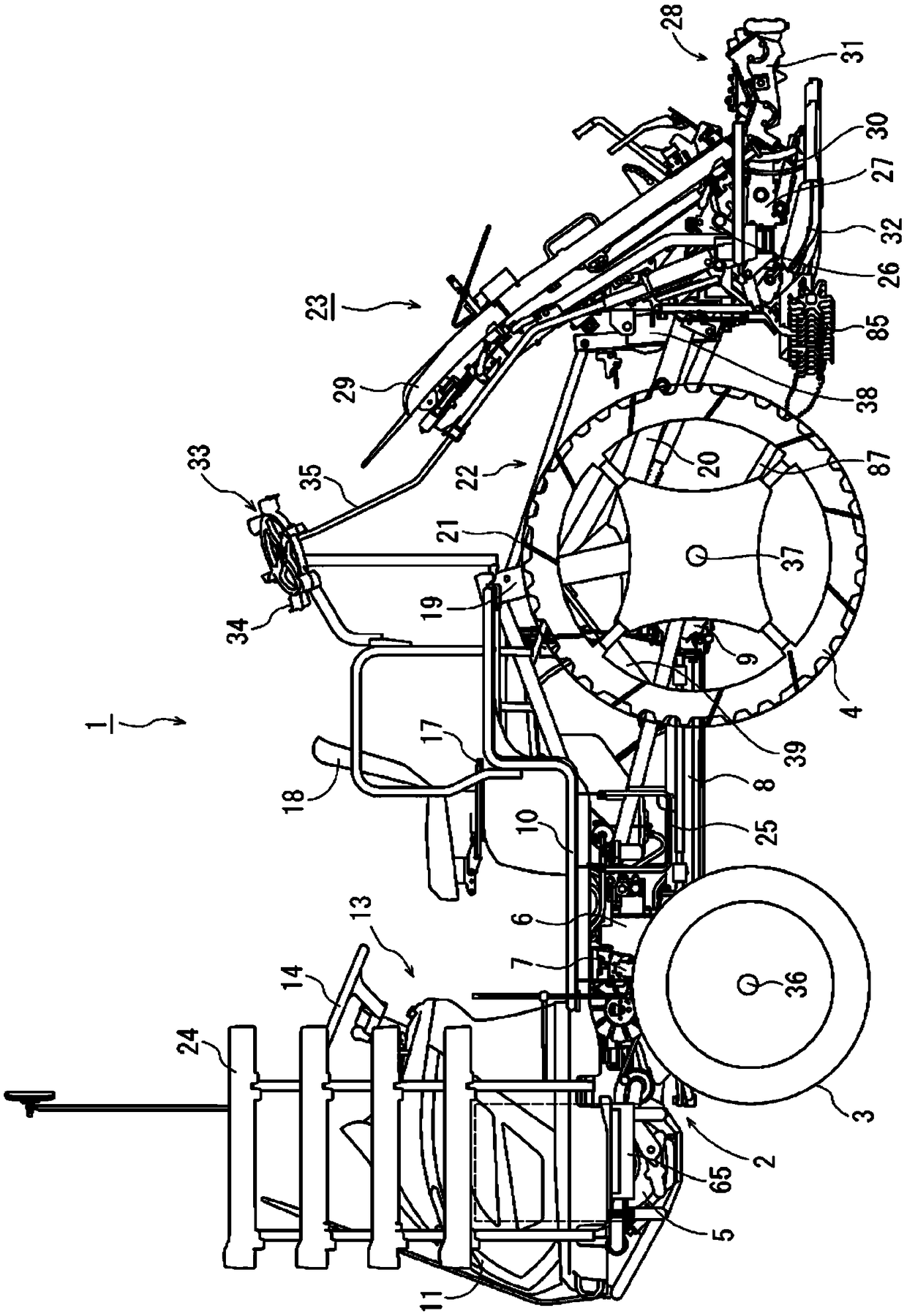

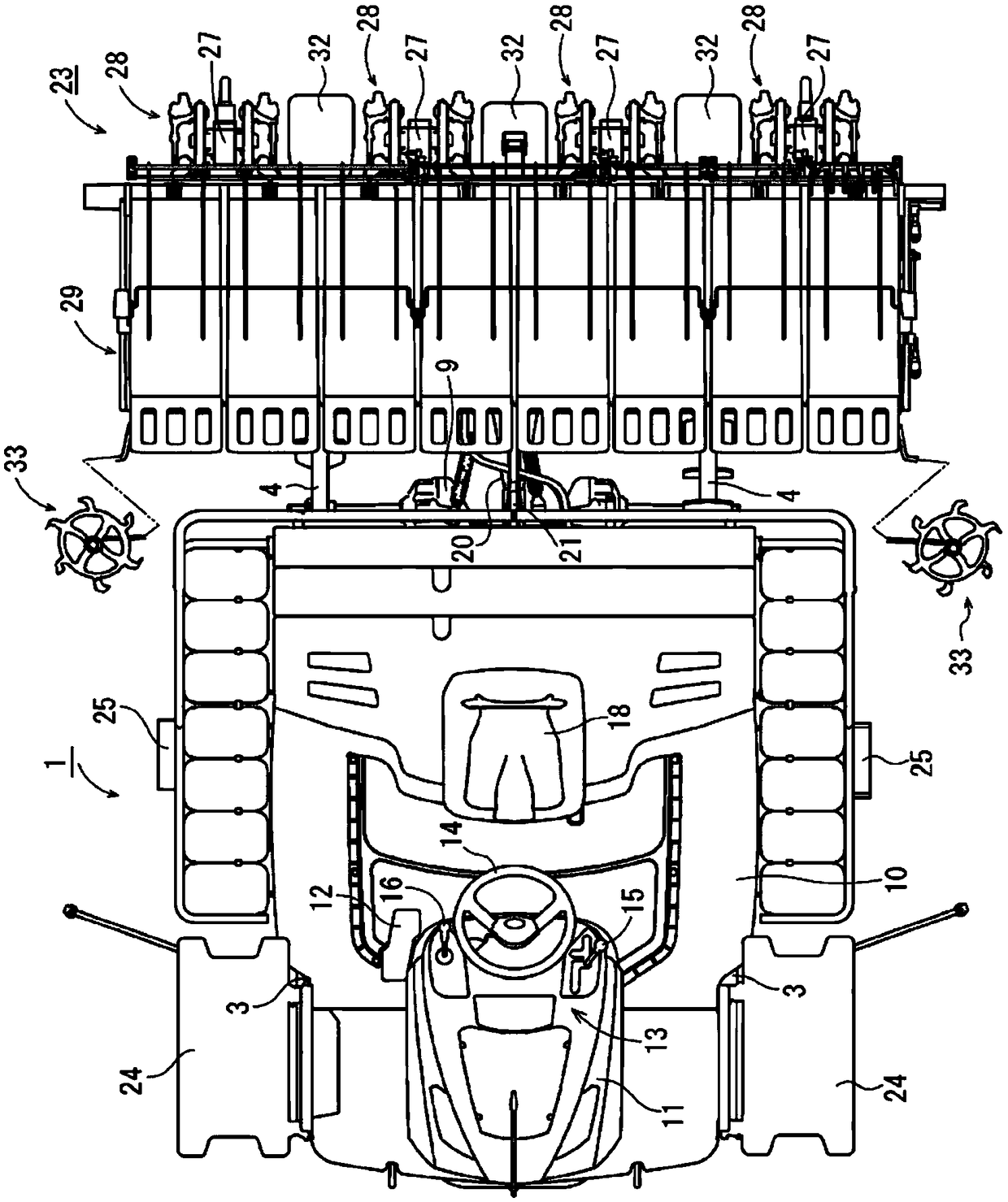

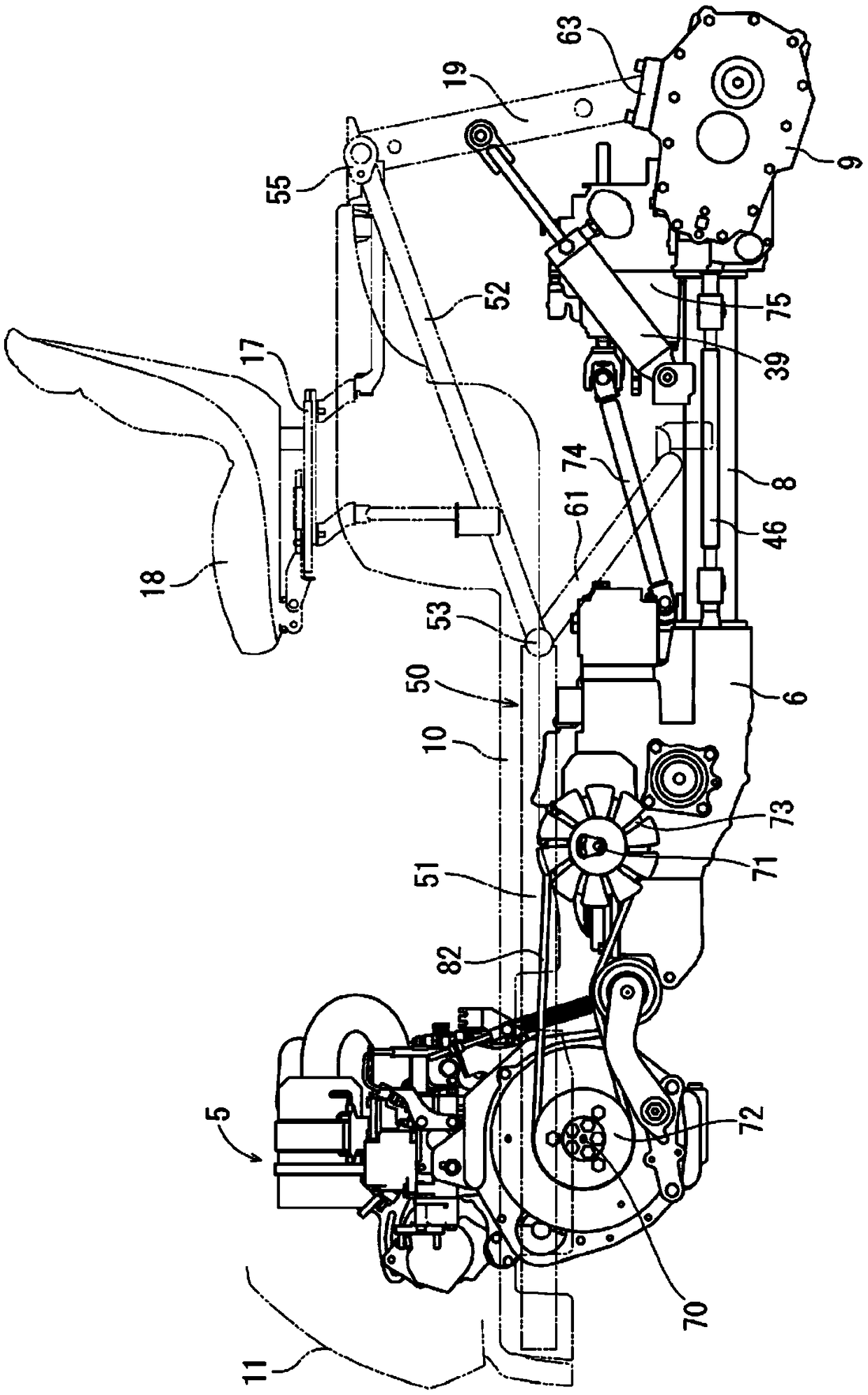

[0035] Hereinafter, it demonstrates based on drawing in the case of applying the embodiment which actualized this invention to the 8-row rice transplanting type riding-type rice transplanter 1 (it abbreviates as rice transplanter 1 hereafter) as a work machine. In addition, in the following description, the left side where the traveling direction of the traveling body 2 is located is simply referred to as the left side, and the right side where the traveling direction is located is simply referred to as the right side.

[0036] First, refer to figure 1 and figure 2 The outline|summary of the rice transplanter 1 is demonstrated. The rice transplanter 1 of embodiment has the traveling body 2 as a traveling part, and this traveling body 2 is supported by the left-right paired front wheel 3 and the left-right paired rear wheel 4 similarly. An engine 5 is mounted on the front portion of the traveling body 2 . By transmitting power from the engine 5 to the rear gearbox 6 to driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com