A workshop-based electric power control system and a control method thereof

A power control system and workshop technology, applied in the workshop-based power control system and its control field, can solve problems such as time delay, electrician inspection trouble, factory loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of a workshop-based power control system and its control method according to the present invention will be described in detail below in conjunction with the accompanying drawings.

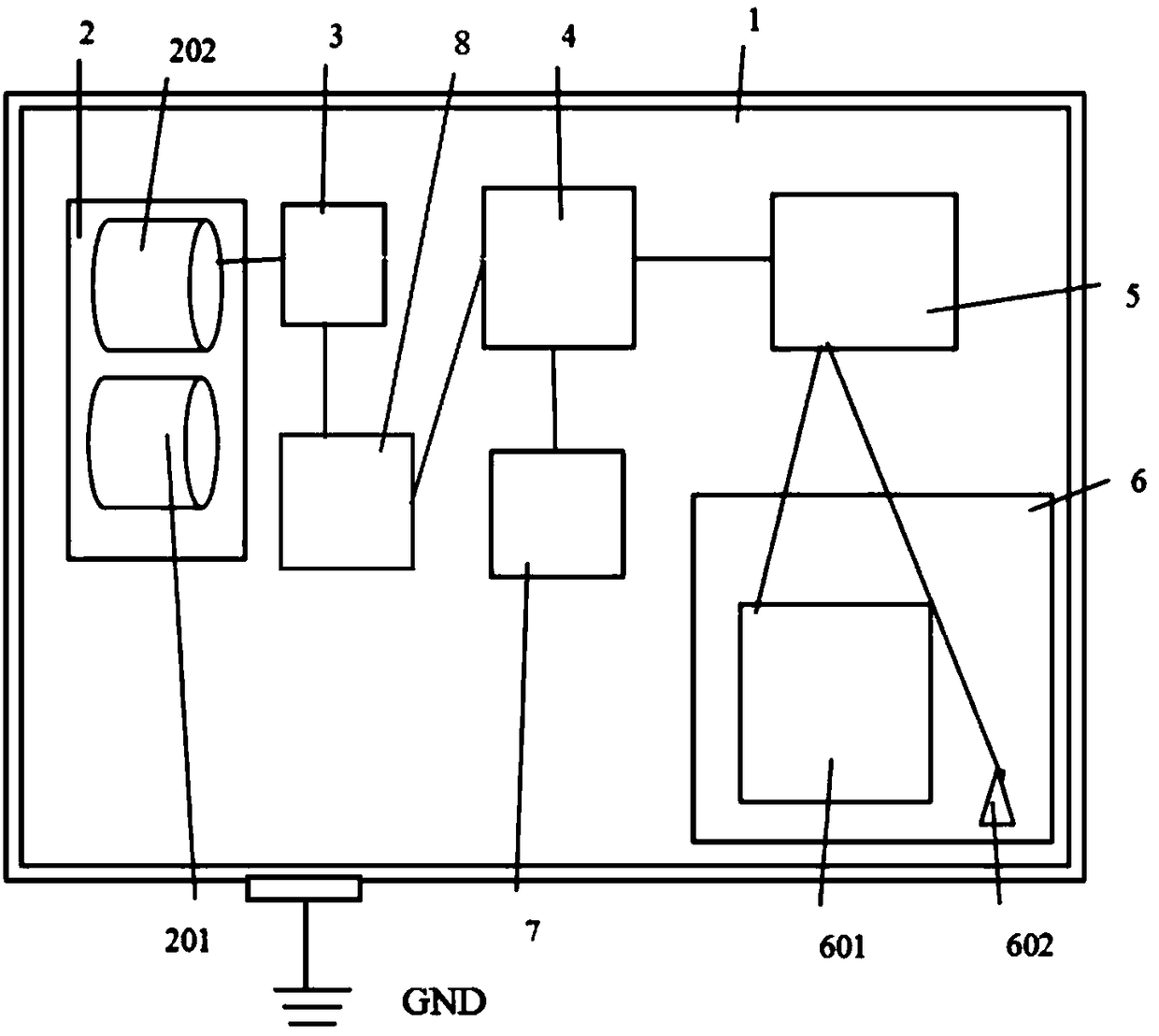

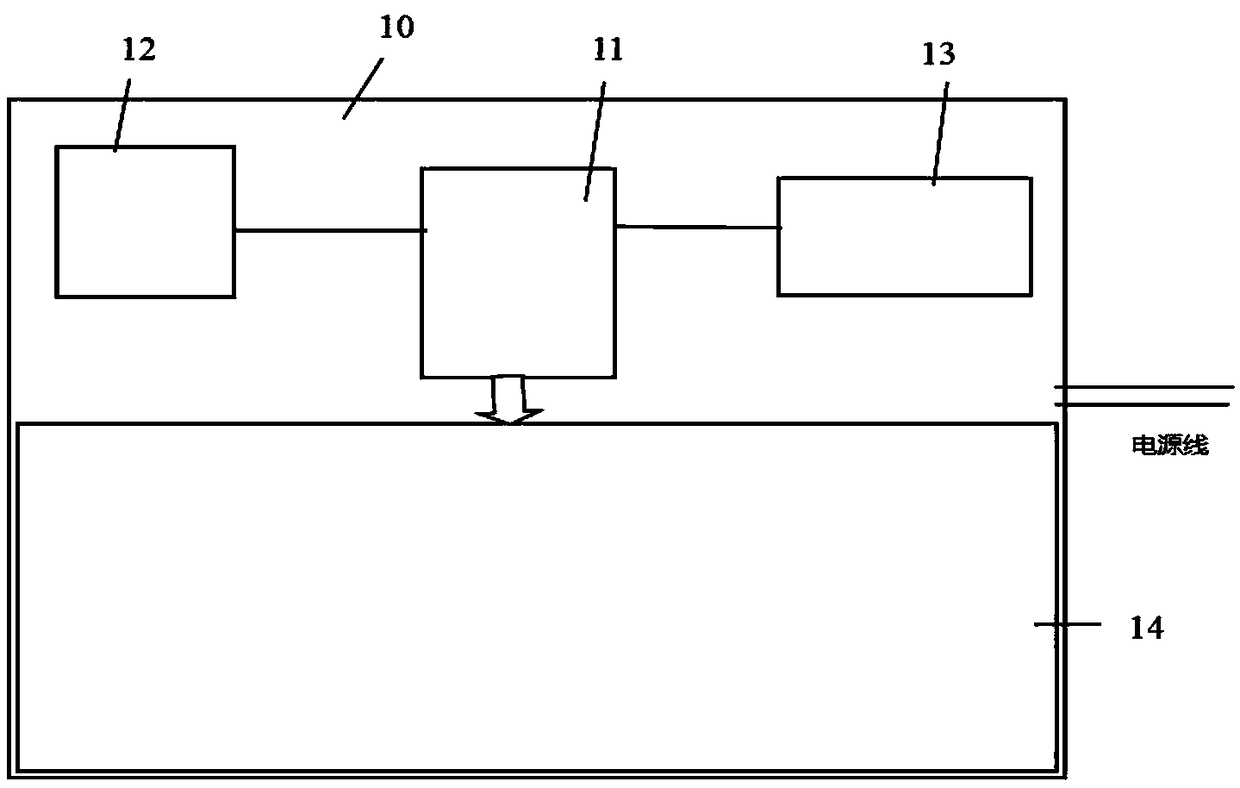

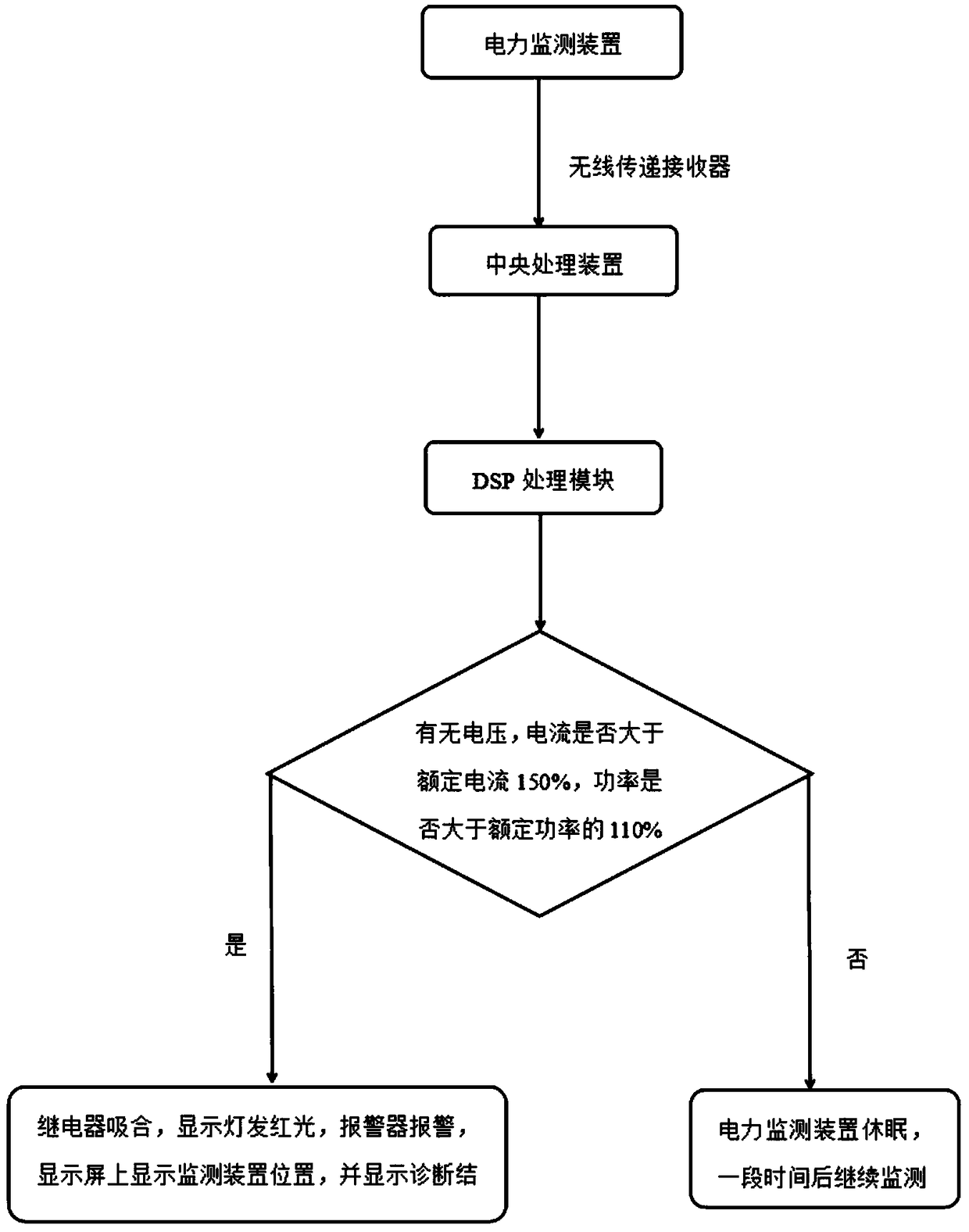

[0026] Such as figure 1 with figure 2 As shown, the workshop-based power control system of the present invention includes a plurality of power monitoring devices and at least one central processing device, wherein the power monitoring device includes an electromagnetic induction coil group 2, a first wireless transfer receiver 4, a grounding module 9, and a controller Module 6, GPS locator 7, DA converter 5, AD converter 8 and filter analysis circuit 3, described electromagnetic induction group 2 comprises first electromagnetic induction coil 201 and second electromagnetic induction coil 202, and described first electric The magnetic induction coil 201 is a helical electromagnetic induction coil used to be wound on the electrical power cord, the second electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com