Lead-acid battery electrolyte mixing device

A lead-acid battery and electrolyte technology, applied in lead-acid batteries, transfer electrolyte devices, secondary batteries, etc., can solve problems affecting battery life, inaccurate open circuit voltage, and potential differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

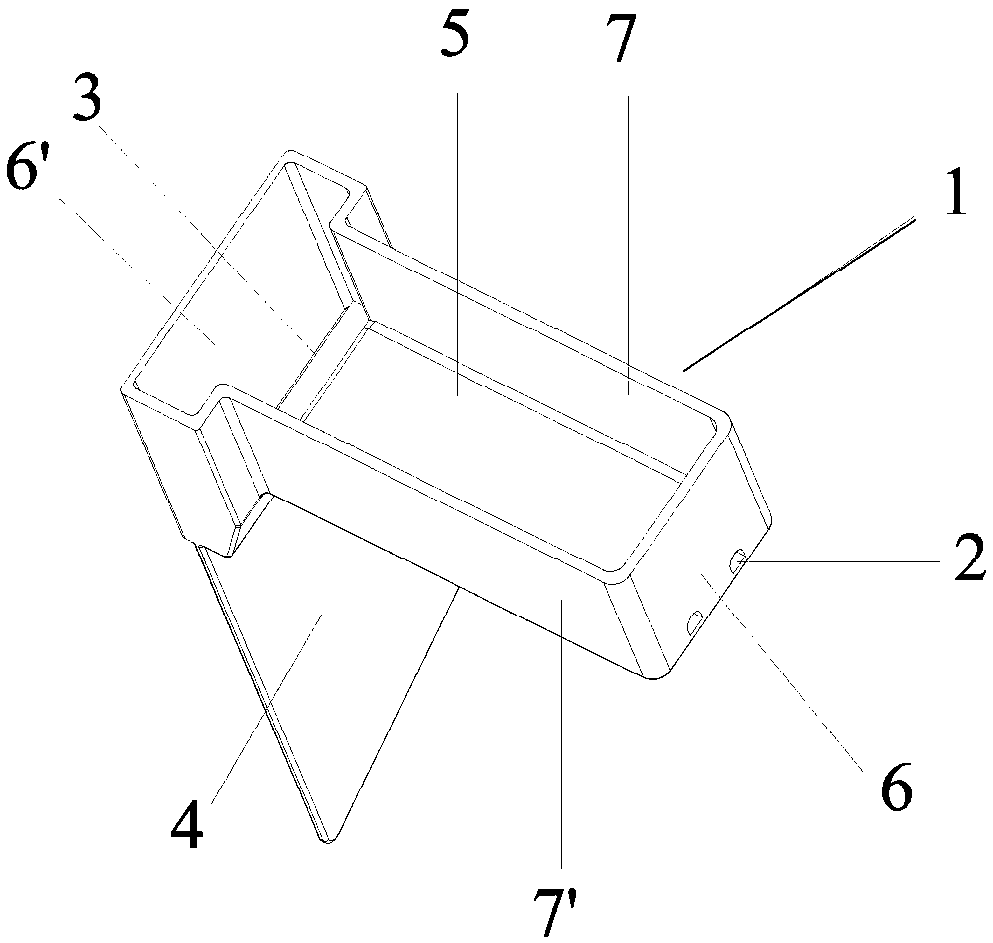

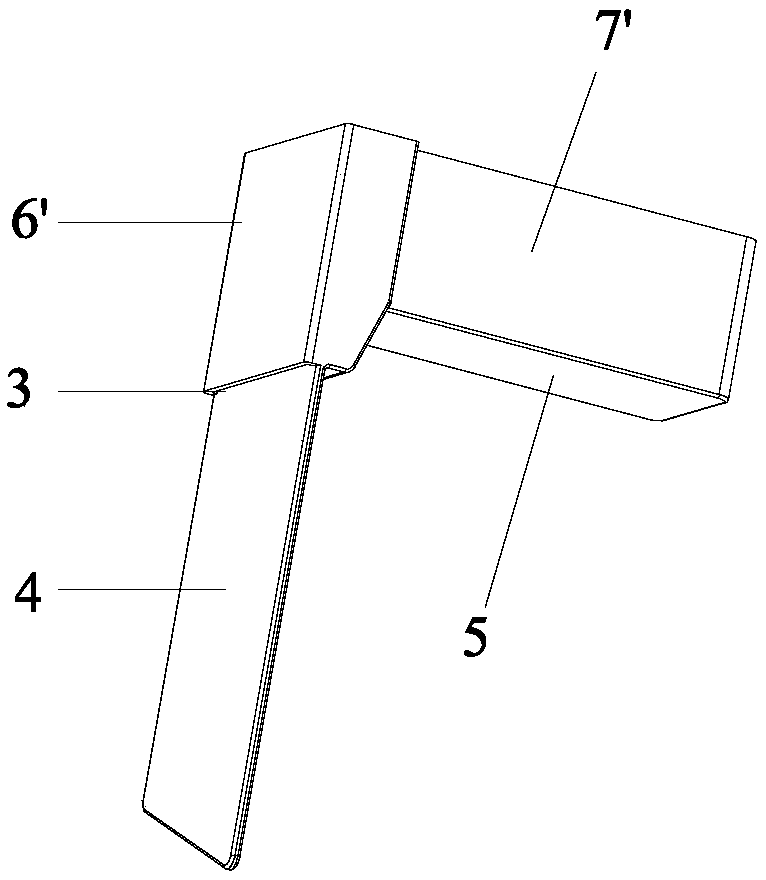

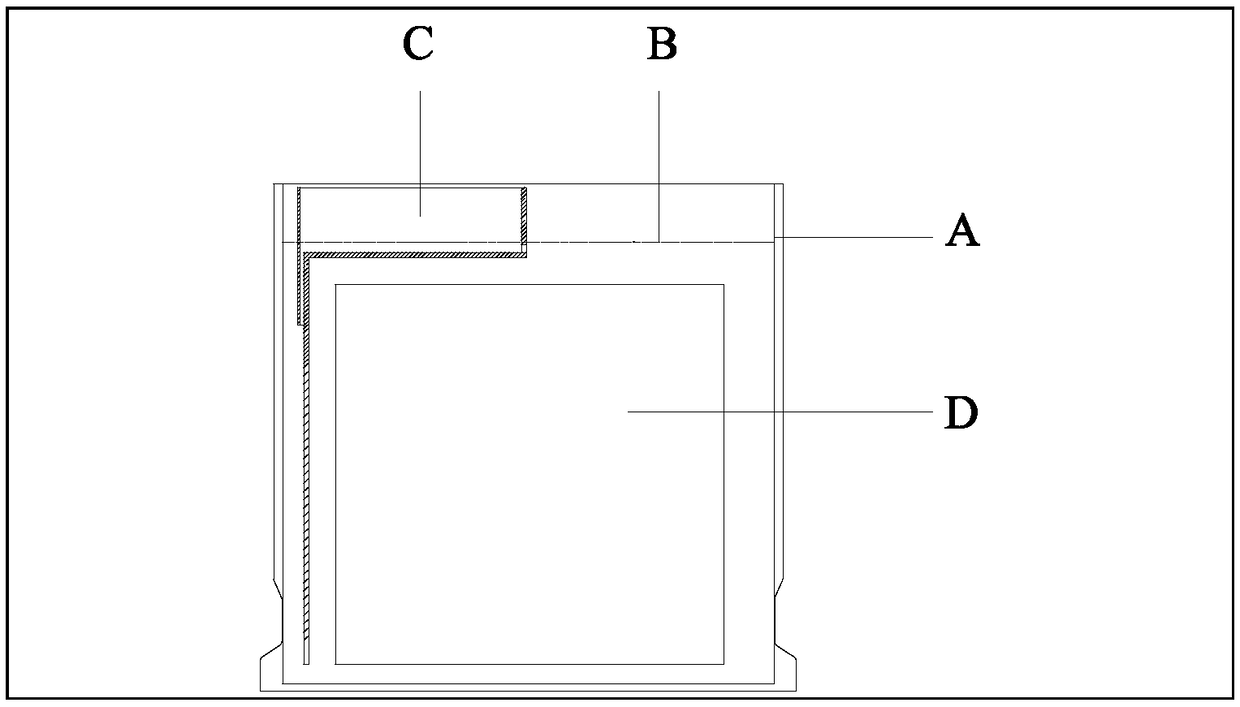

[0031] figure 1Shown is an exemplary, typical lead-acid battery electrolyte mixing device of the present invention. Its basic structure includes storage tank 1 , inlet 2 , outlet 3 and deflector 4 . The storage tank 1 is enclosed by a bottom wall 5, two opposite long side walls 7, 7' and two opposite short side walls 6, 6', the inflow port 2 is located on the first short side wall 6, and the outflow port 3 Located at the position of the bottom wall 5 close to the second short side wall 6 ′, the deflector 4 extends from the lower surface of the bottom wall 5 parallel to the second short side wall 6 ′, so that the outlet 3 is located on the second short side wall 6 ' and deflector 4 between. The area of the outflow port 3 is designed to be larger than the area of the inflow port 2 .

[0032] Such as figure 1 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com