Implementation method of automatic checking for apparent quality of digital and analog signals

An apparent quality, automatic inspection technology, applied in office automation, data processing applications, electrical digital data processing and other directions, can solve the problems of many inspection items, long inspection cycle, inspection quality impact, etc., to achieve simple development and maintenance, suitable for The effect of broad scope, data management and simple organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

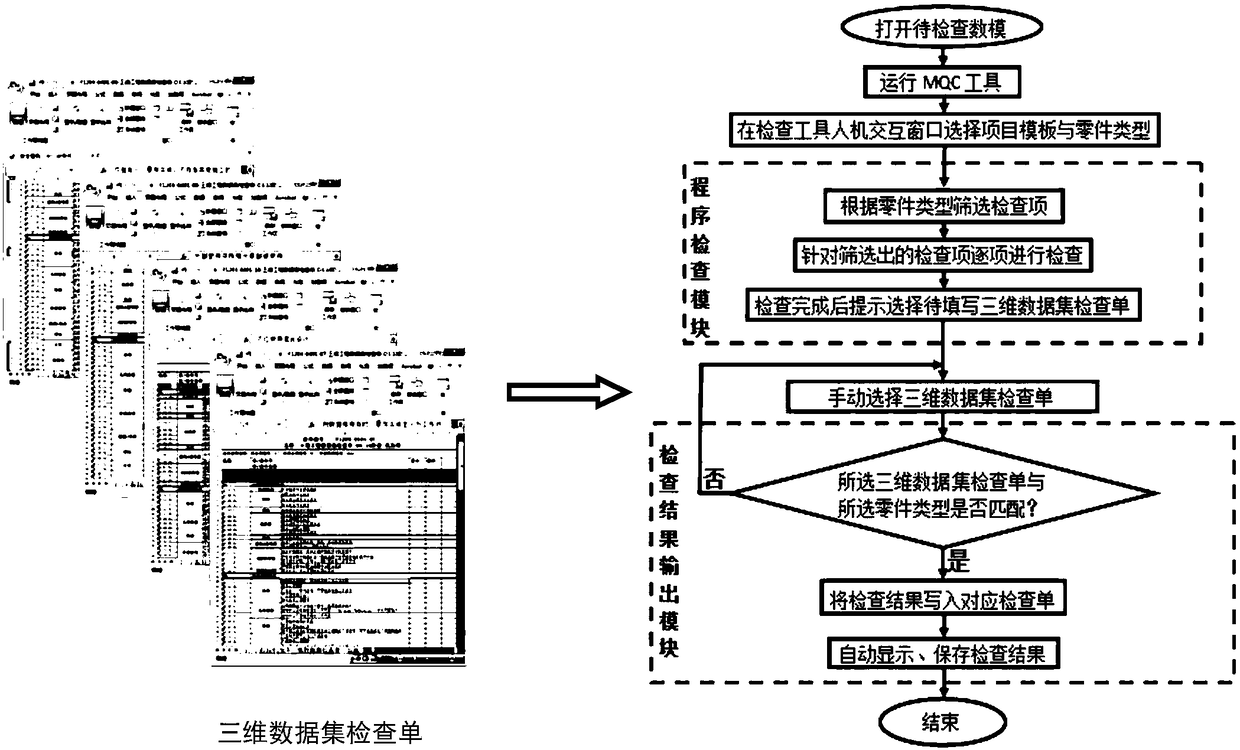

[0039] An implementation method for automatically checking the apparent quality of digital models of parts, using the secondary interface provided by CATIA software, developing an automatic inspection tool based on VB program, and modularizing the appearance quality inspection according to the selected project template and part type content and execute the inspection program, and manage the results of the apparent quality inspection of the digital model of the part through the standard data set checklist.

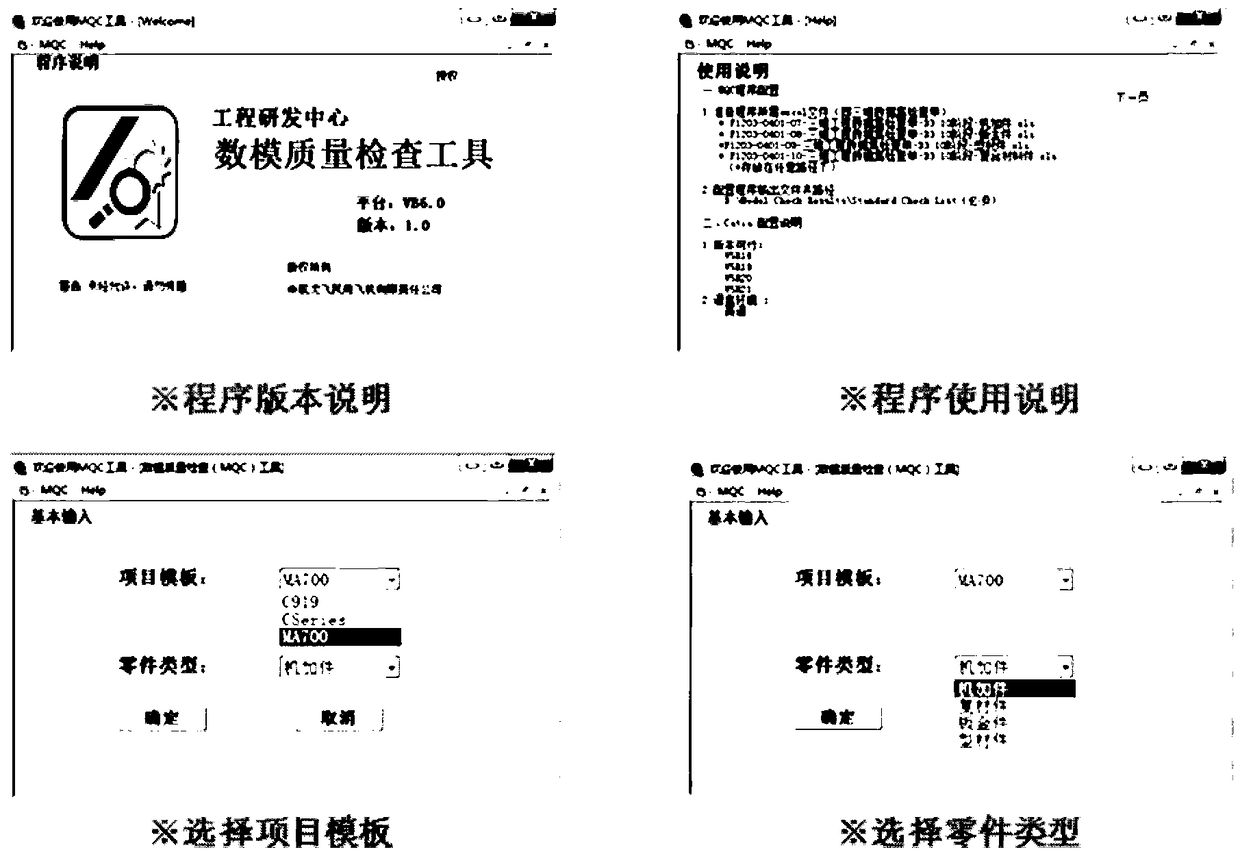

[0040] The automatic inspection tool includes a client and a browser. The client is a basic input menu. The browser end is a three-dimensional dataset checklist. The automatic inspection tool for the apparent quality of the digital model of the part is independent of CATIA software and will not be limited by the CATIA version. It consists of a client, a program inspection module and an inspection output module.

[0041] The client is used to define the basic input require...

example 2

[0049] open first Figure 4 Corresponding to the digital model of the part to be inspected; then start the apparent quality automatic inspection tool, configure the basic input menu, select the project template and part type, and click OK to run the apparent quality inspection program. The tool starts to check the apparent quality of the part, completes 50 checks and gives the time required for the check. Finally, the tool prompts the user to select the 3D dataset checklist corresponding to the part type as the check result output file.

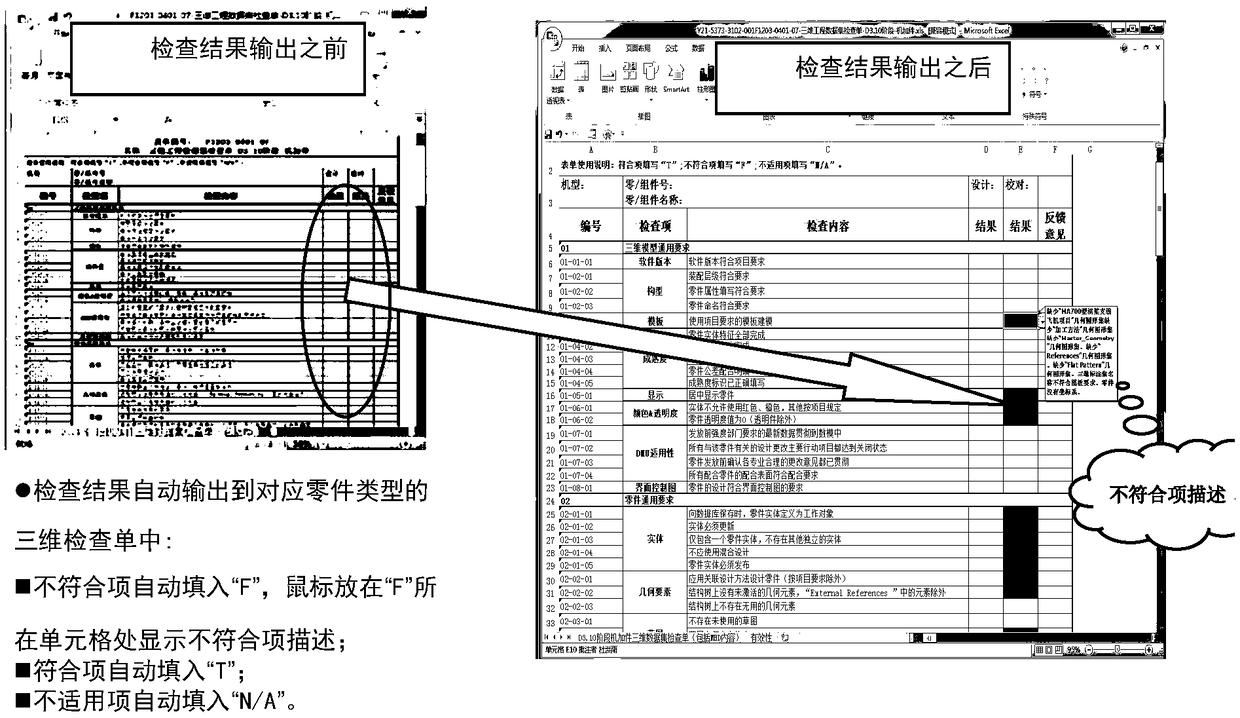

[0050] Such as Figure 5As shown in , the apparent quality inspection results are output to the 3D data set check list corresponding to the part, and the inspection results related to the apparent quality are automatically marked, and the cause of the error is analyzed, and combined with the results of other non-apparent quality inspection items ( Such as functionality, tolerance matching requirements, etc.), which can quickly reflect the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com