High-concentration ore pulp concentration detection device and method

A pulp concentration and detection device technology, which is applied in the detection field, can solve the problems of radioactivity, large error, and inaccurate measurement of the nuclear concentration meter, and achieve the effects of shortening the waiting time, realizing accurate detection, and alleviating deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

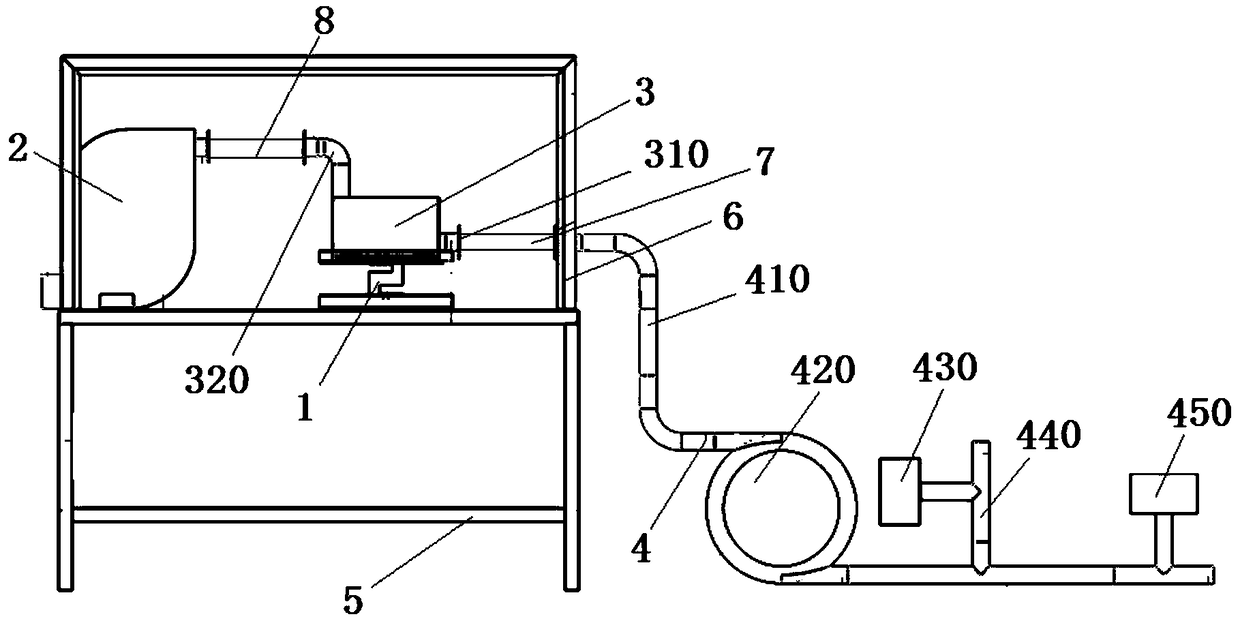

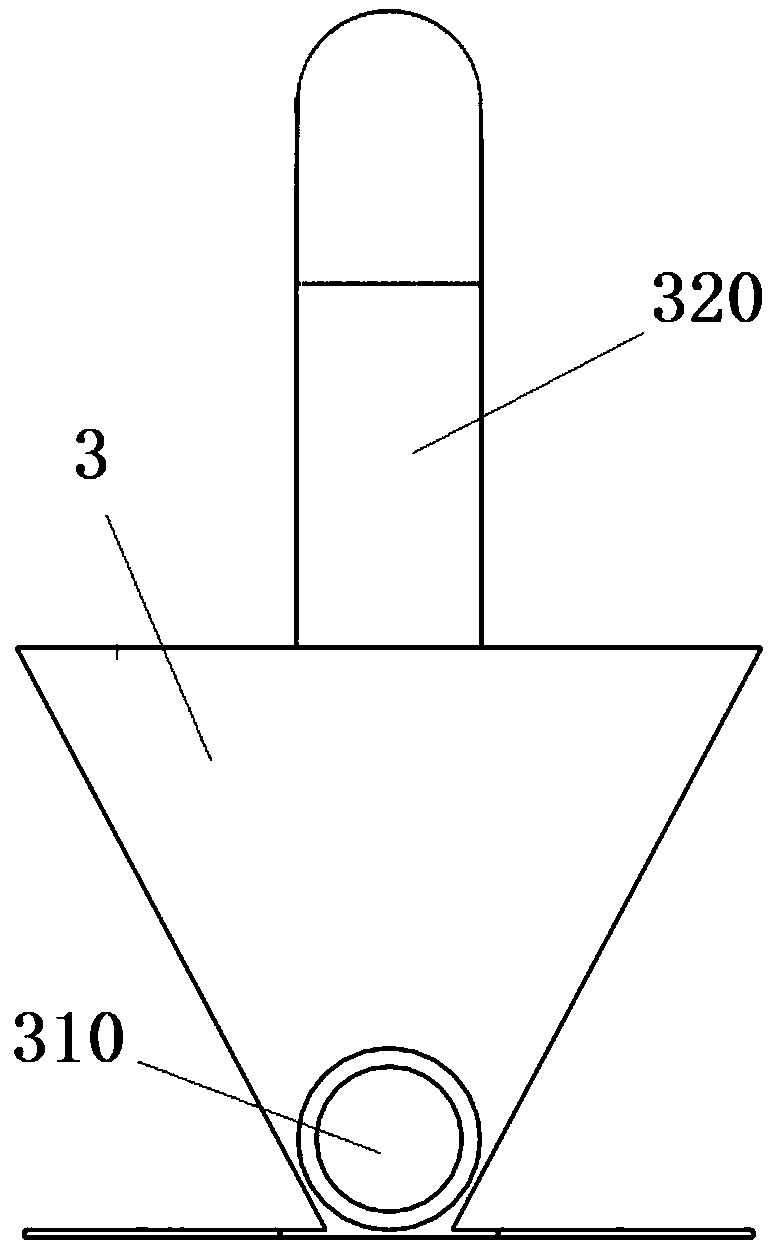

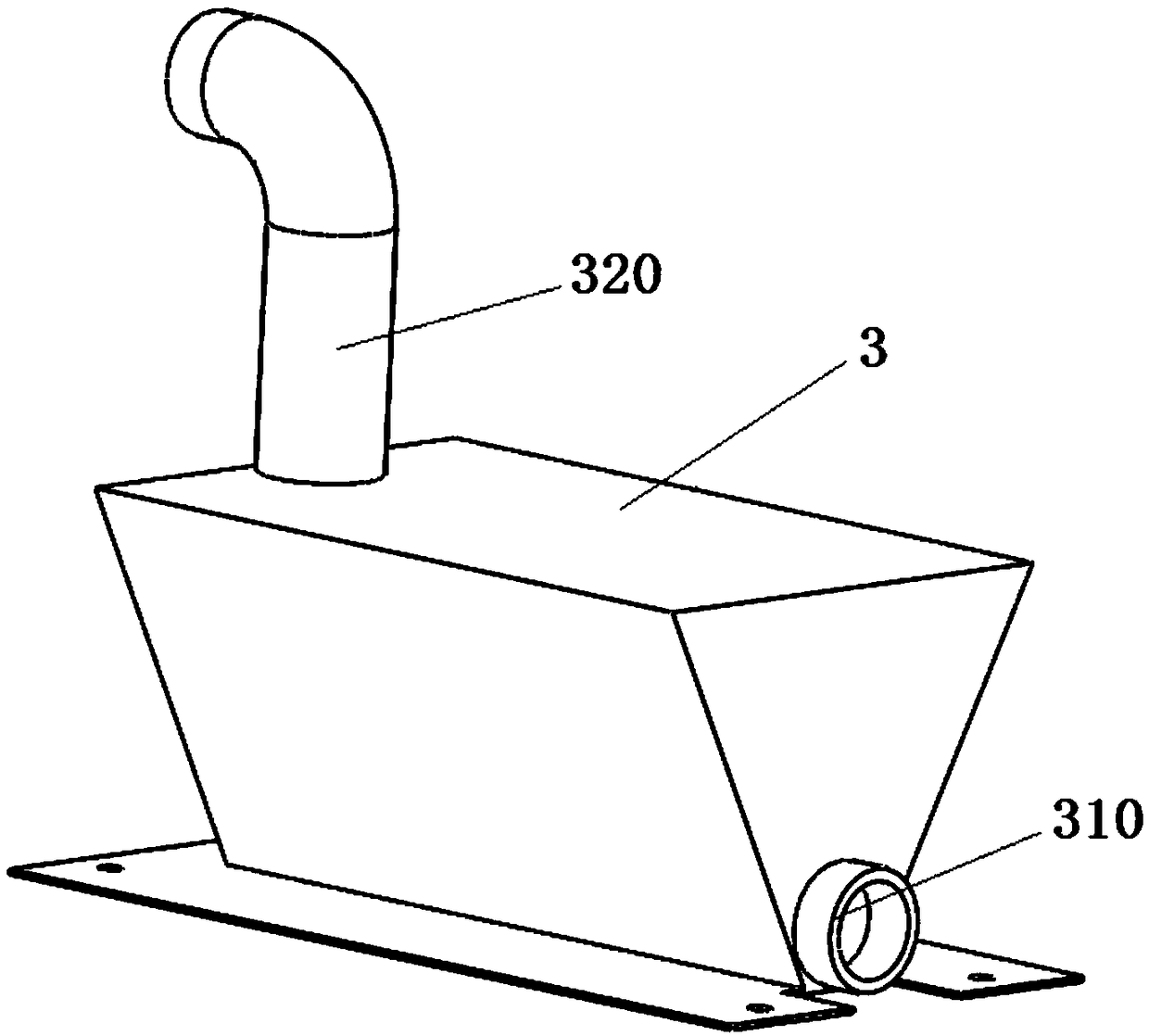

[0031] Such as figure 1 , figure 2 , image 3 As shown, a high-concentration pulp concentration detection device includes a weighing unit 1, a host, a pulp storage box 3, a pulp diversion box 2, and a pulp pumping assembly 4. The pulp storage box 3 has a structure with a wide top and a narrow bottom. The side wall of the storage box 3 is provided with a feed port 310 near the bottom, the width of the bottom of the pulp storage box 3 is slightly larger than the diameter of the feed port 310, and the discharge port 320 of the pulp storage box 3 is connected through the second hose 8 Connect the feed end of the pulp diversion box 2, the second hose 8 is made of silica gel, the outlet 320 of the pulp storage box 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com