LED lighting fixture for home plant factory

A technology of LED lighting and LED chips, applied in lighting devices, lighting and heating equipment, gardening tools/equipment, etc., can solve the problems of dazzling light and difficult to reach the number of red and blue particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The design method will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

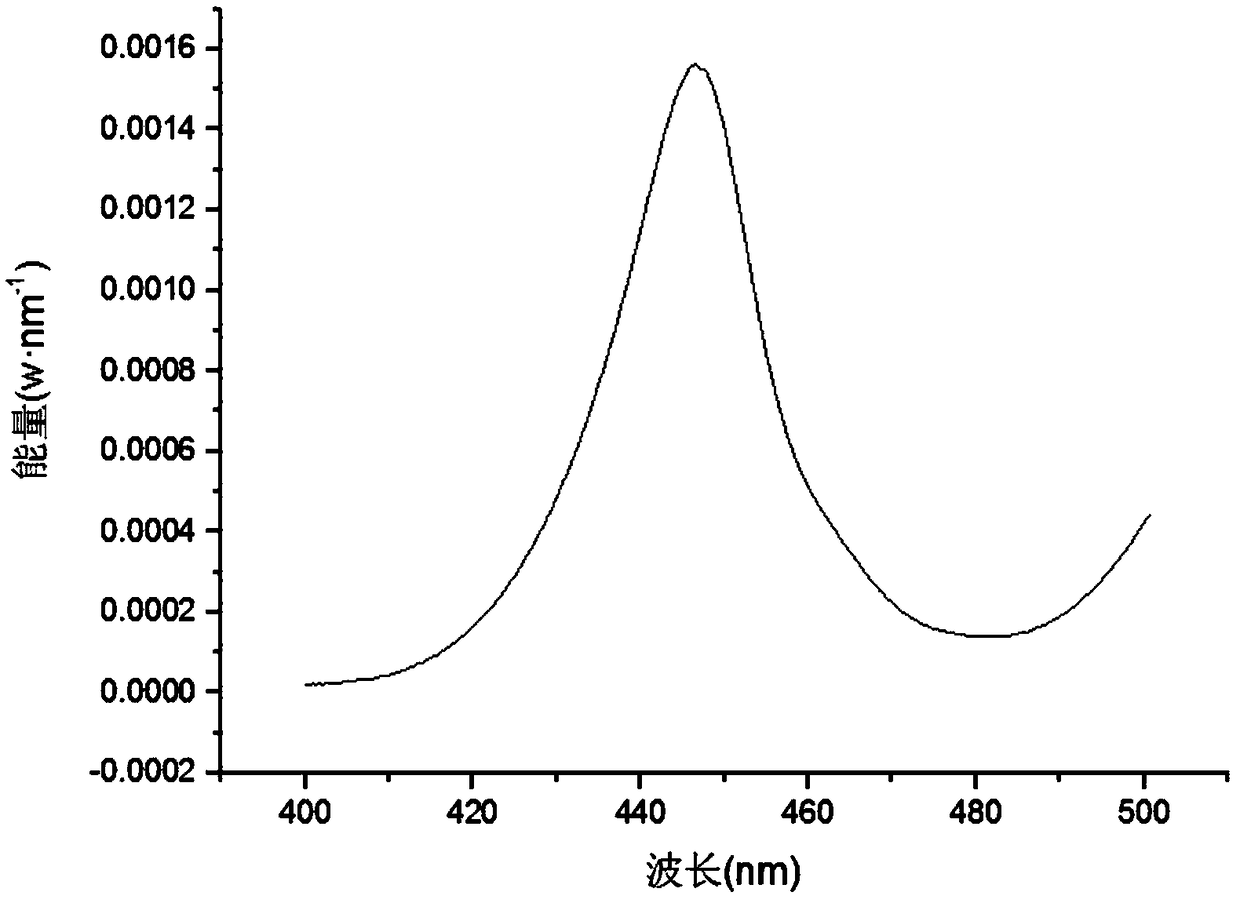

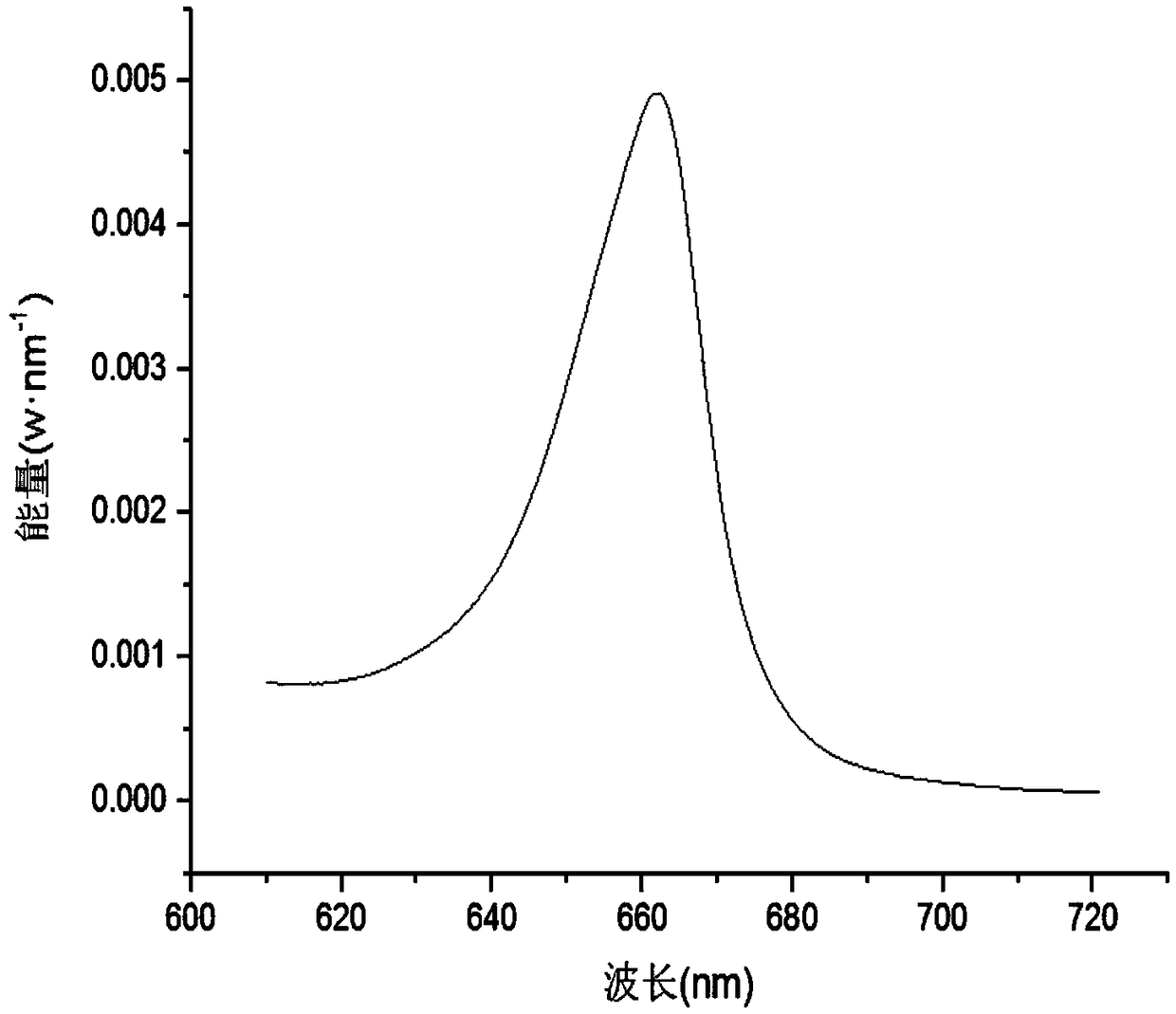

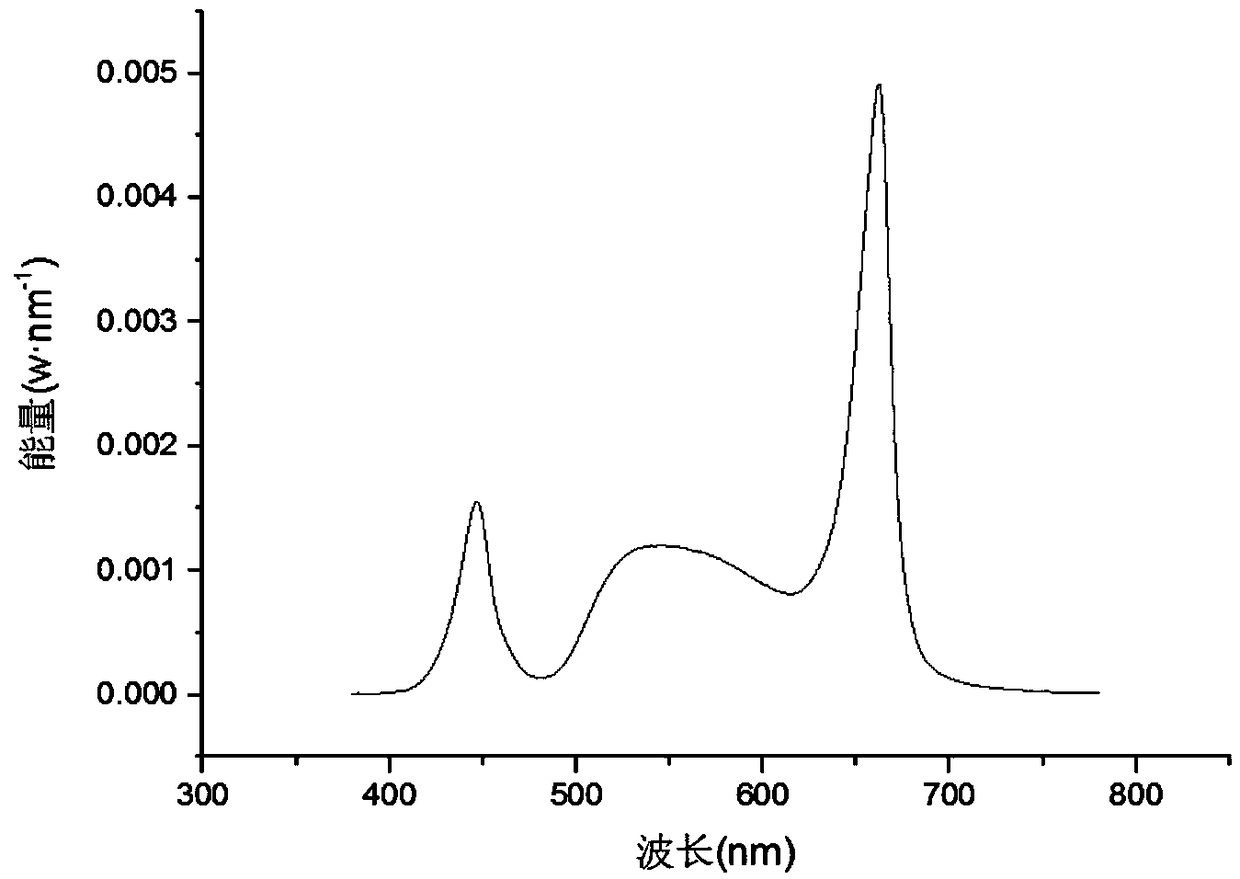

[0013] An LED lighting fixture for a family plant factory provided by the present invention includes: a lamp board, on which a first LED chip composed of a red LED chip and a blue LED chip in series is arranged on the lamp board, and a red LED chip and a blue LED chip A second LED chip composed of blue LED chips connected in parallel (the two chips have independent positive and negative pins); the first LED chip and the second LED chip are excited to produce white light acceptable to human eyes, and the generated The ratio of the number of red and blue photons is 9:1.

[0014] In a preferred embodiment of the present application, the spectral structure generated by the lamp is adjusted according to the ratio of the phosphor, so that when the red LED chip in the second LED chip passes the maximum rated current, the red The ratio of the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com