Control method of low-power solenoid valve with position state monitoring

A control method and solenoid valve technology, applied in the field of solenoid valves, can solve problems such as high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A control method of a low-power solenoid valve with position state monitoring of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

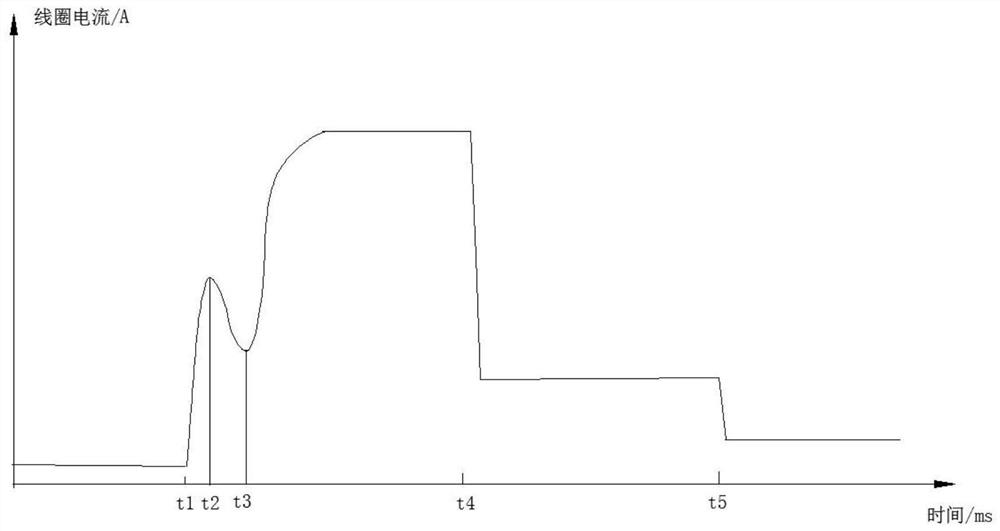

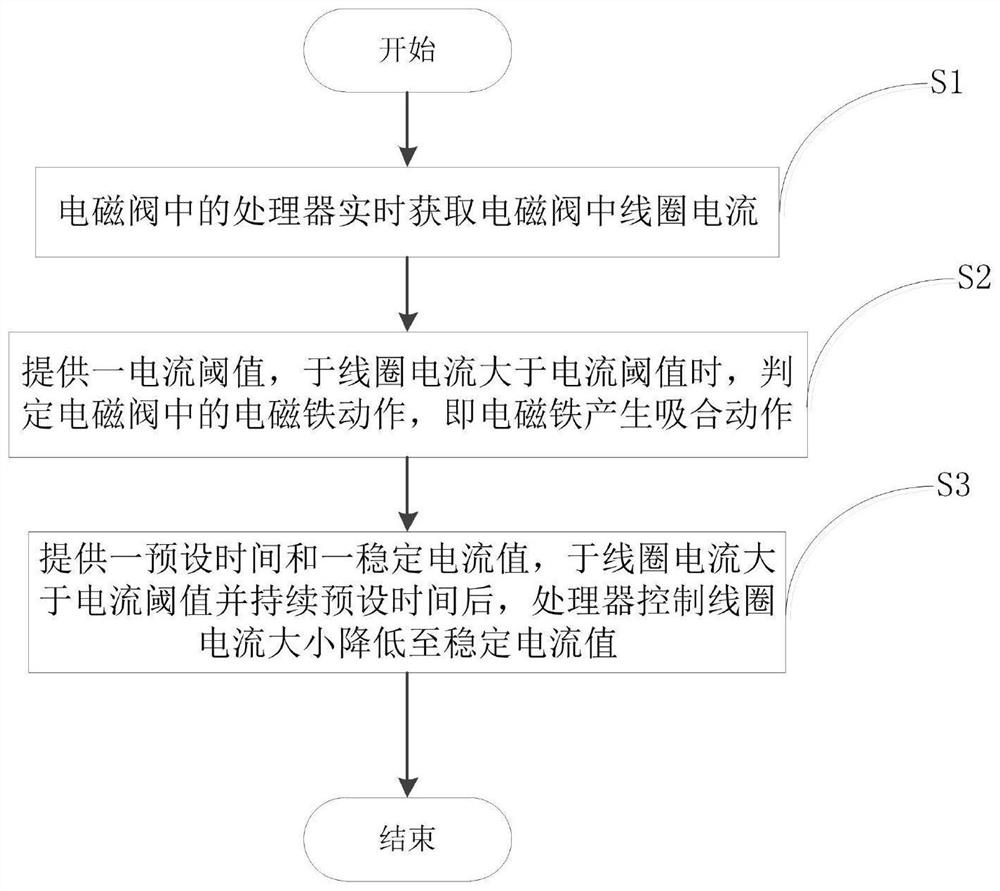

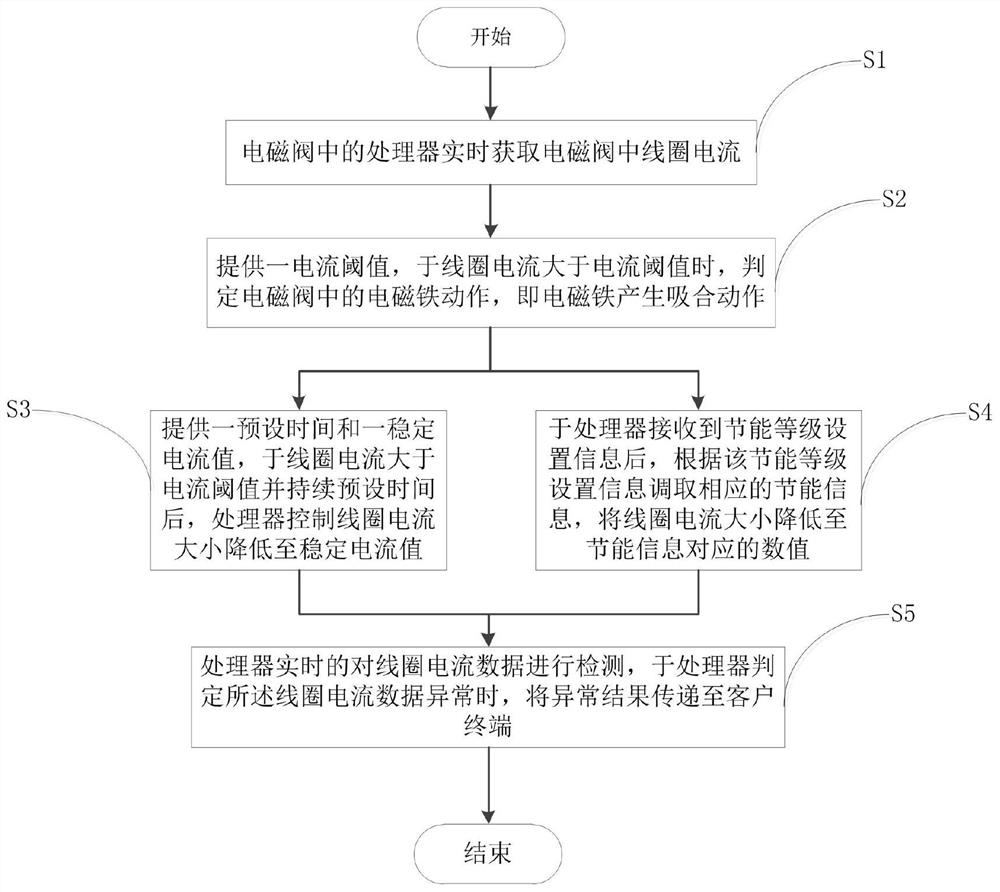

[0028] Such as figure 1 with figure 2 As shown, a control method of a low-power solenoid valve with position status monitoring, comprising steps:

[0029] S1. The processor in the solenoid valve obtains the coil current in the solenoid valve in real time;

[0030] S2, providing a current threshold, when the coil current is greater than the current threshold, it is determined that the electromagnet in the solenoid valve acts, that is, the electromagnet generates a pull-in action;

[0031] S3. Provide a preset time and a stable current value. After the coil current is greater than the current threshold for a preset time, the processor controls the coil current to decrease to the stable current value.

[0032] Specifically, in the control method of the above-mentioned low-po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com