A system and method for detecting oxygen content and nitrogen oxide concentration in coke oven flue gas

A technology for flue gas oxygen content and nitrogen oxides, which is used in the analysis of gas mixtures, measurement devices, and liquid/vacuum measurement for liquid tightness. , the tightness of the coke oven cannot be reflected in time, etc., to reduce the labor intensity, reduce the operating cost of the coke oven, and facilitate the overall control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

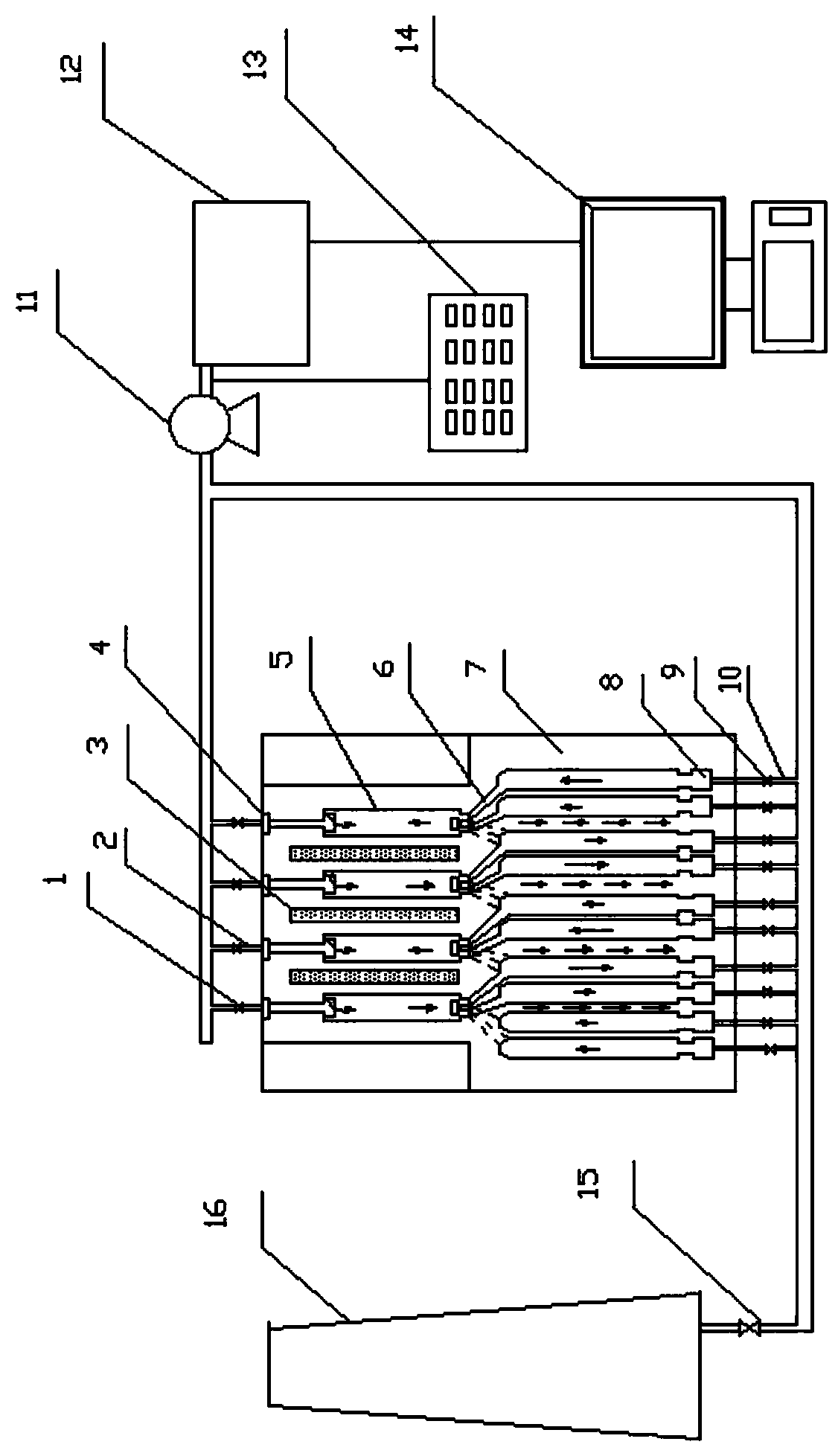

[0024] See figure 1 , is a schematic structural diagram of the detection system of the present invention. A coke oven flue gas oxygen content and nitrogen oxide concentration detection system according to the present invention includes a fire hole sampling tube 2, a small flue sampling tube 10, an air extraction pump 11, a flue gas analysis device 12 and a data storage system 14 , the sampling tube 2 for viewing the fire hole is arranged on a certain selected fire viewing hole 4 in each combustion chamber of the coke oven, and the small flue sampling tube 10 is arranged on the small flue 8 at the bottom of each combustion chamber; the sampling tube for viewing the fire hole 2 communicate with the small flue sampling pipe 10 through sampling pipes, the sampling pipes are respectively connected with the air extraction pump 11 and the chimney 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com