Rotating shaft bearing structure and motor

A technology of axial bearing and rotating shaft, applied in the field of rotating shaft bearing structure and motor, can solve the problems of rotating shaft collision, affecting the normal operation of the motor, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

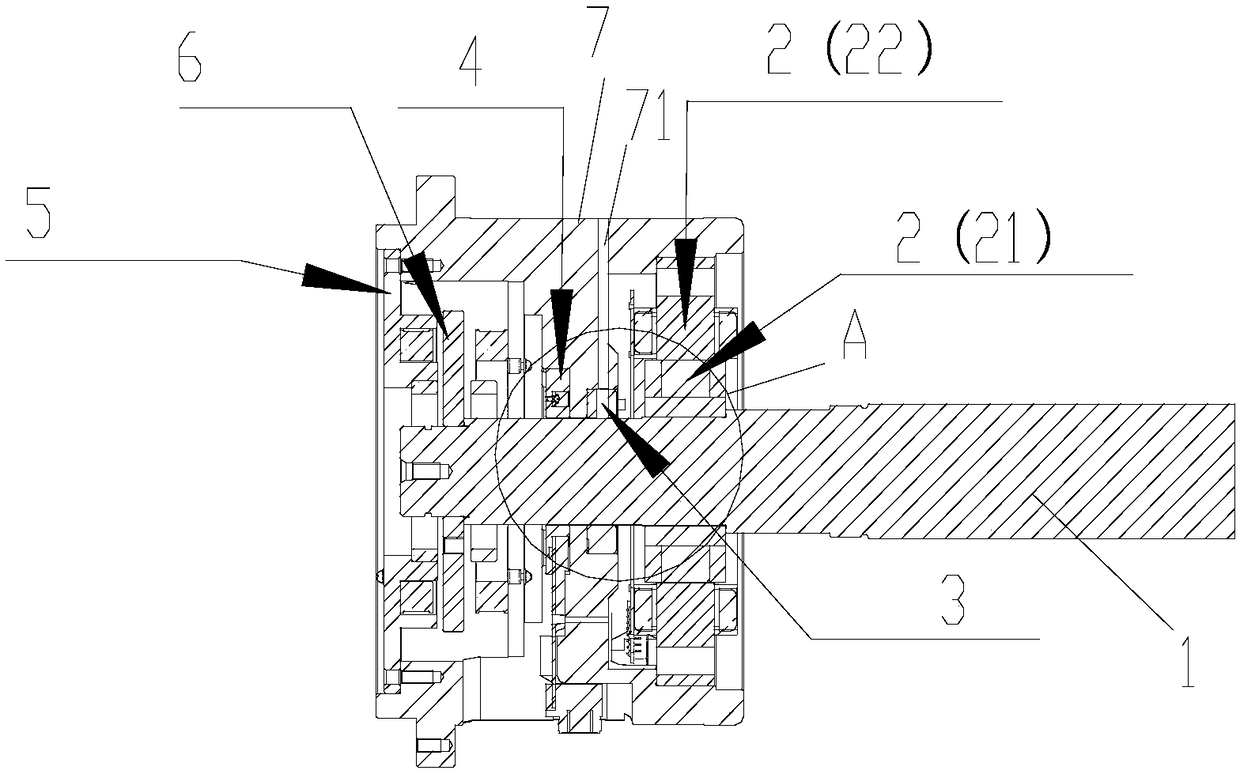

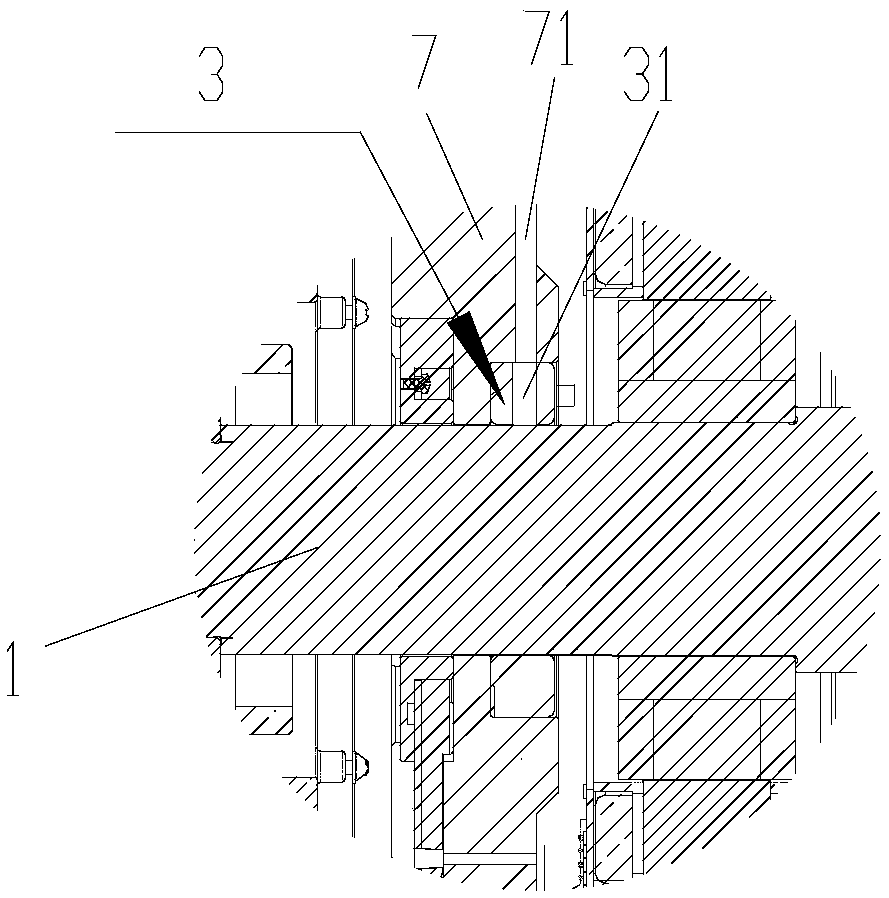

[0036] Such as Figure 1-3 As shown, the present invention provides a rotating shaft bearing structure, which includes:

[0037] Spindle 1;

[0038] The magnetic suspension radial bearing 2 is sleeved on the rotating shaft 1;

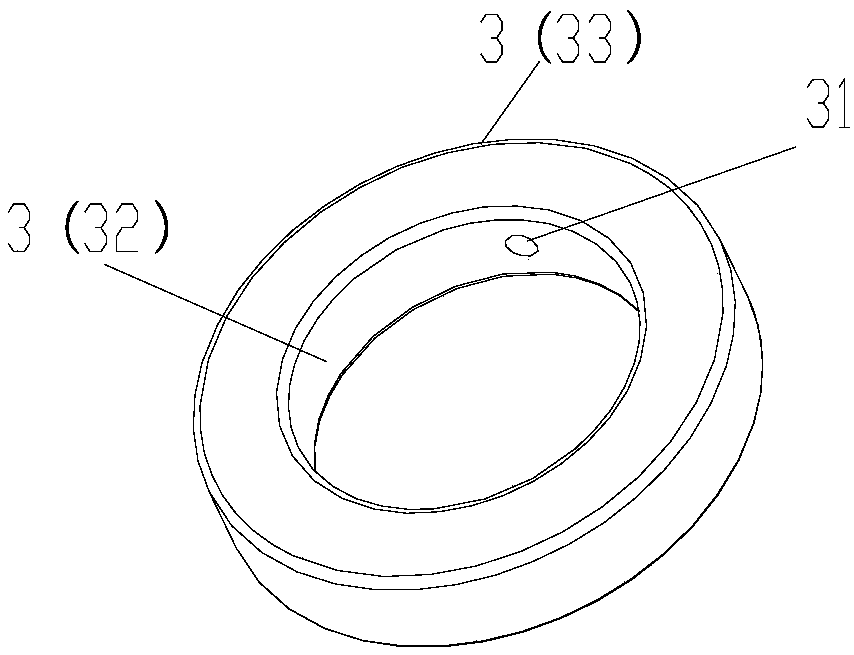

[0039] The static pressure bearing 3 is sleeved on the rotating shaft 1, and the static pressure bearing 3 and the magnetic levitation radial bearing 2 are located at different positions in the axial direction of the rotating shaft 1, and the static pressure bearing 3 A vent hole 31 is provided, one end of the vent hole 31 communicates with the radially inner wall of the hydrostatic bearing, and the other end of the vent hole 31 communicates with the radially outer wall of the hydrostatic bearing 3, so as to be able to The outside of the hydrostatic bearing 3 passes gas with a certain pressure to the gap between the radially inner wall of the hydrostatic bearing 3 and the rotating shaft 1 .

[0040] In the present invention, air holes are provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com