Fixed pressing block and air conditioning unit

A groove and body technology, applied in the field of fixed pressure blocks and air-conditioning units, can solve the problems of cumbersome installation of fixed pressure blocks, and achieve the effect of convenient and fast switching process, ensuring aesthetics, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

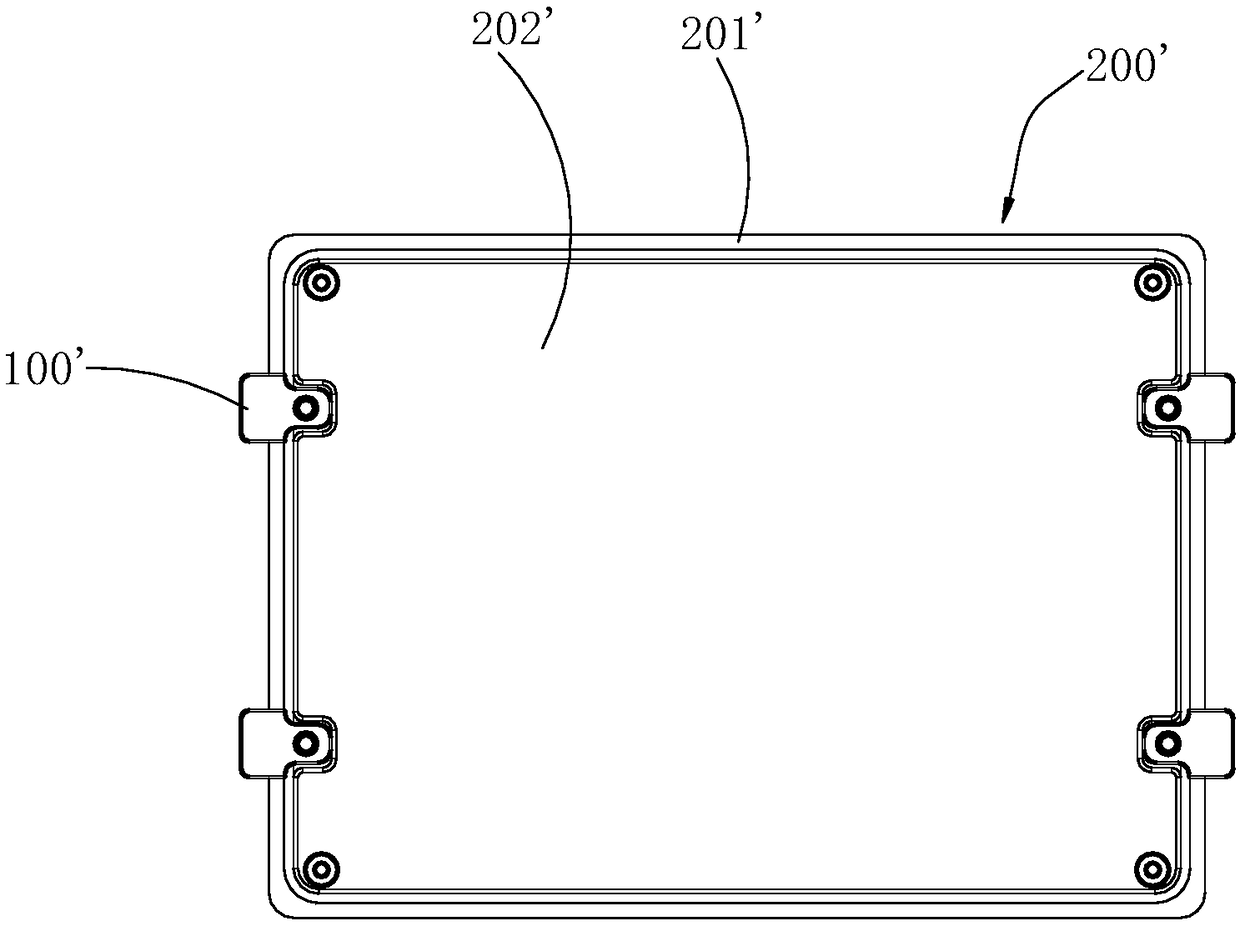

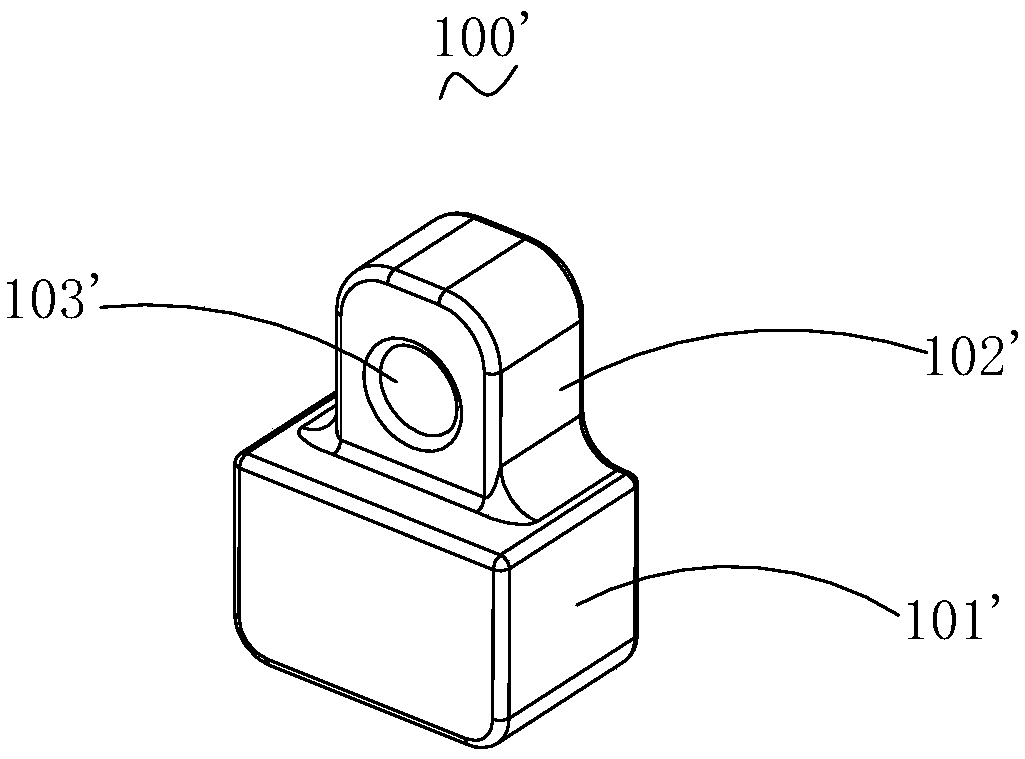

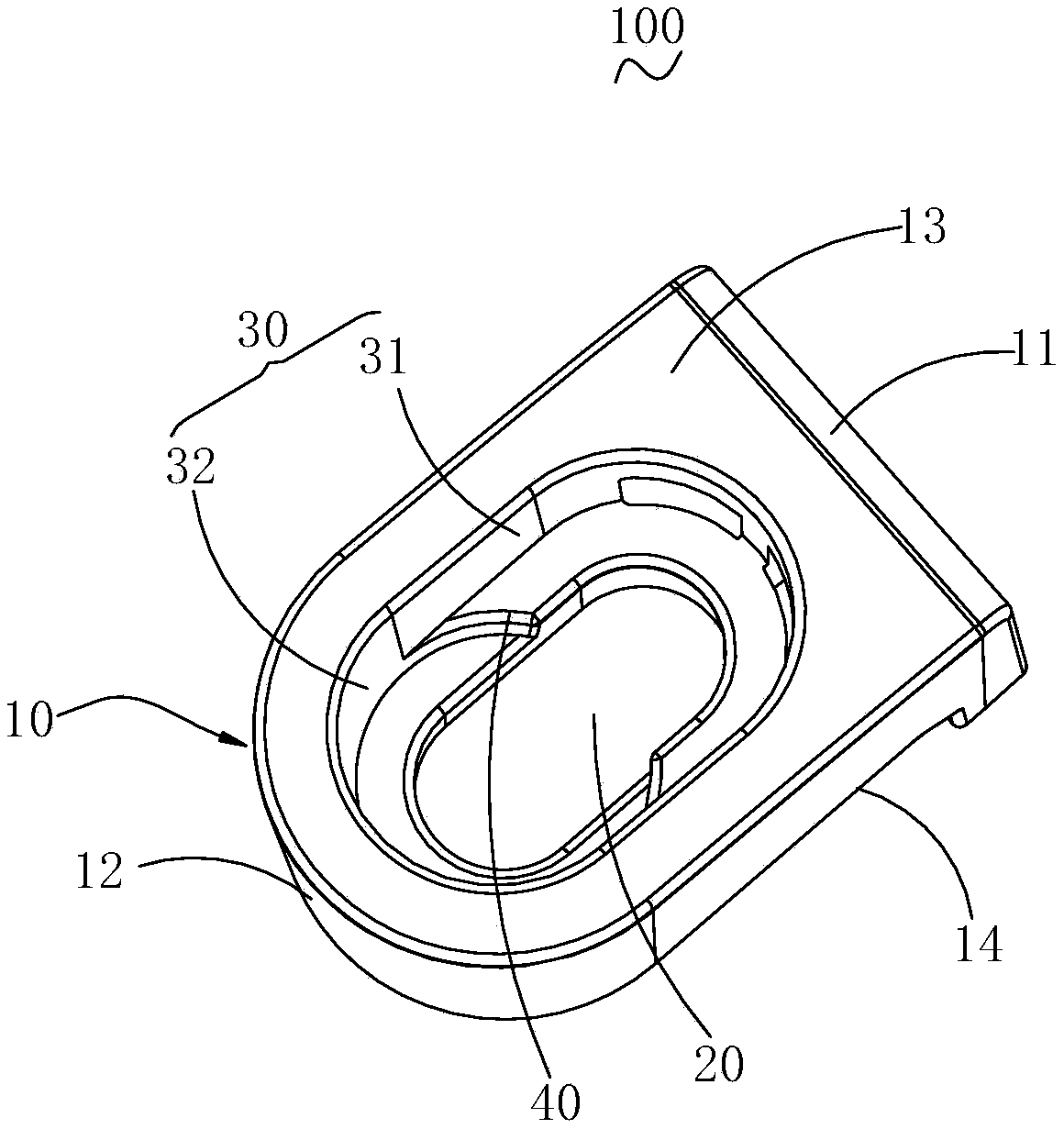

[0044] see Figures 3 to 8, is a fixed pressure block 100 according to Embodiment 1 of the present invention, which is used to install on the target body 200 through the installation accessory 300. The installation accessory 300 includes a connected screw rod 310 and a flange 320, and the screw rod 310 is screwed to the target body 200. The flange 320 is used to prevent the fixed pressing block 100 from detaching from the mounting fitting 300 ; the back of the target body 200 is provided with a notch 201 corresponding to the fixing pressing block 100 . The fixed briquetting block 100 includes a briquetting block body 10, the briquetting block body 10 has a first end 11 and a second end 12 arranged oppositely, the briquetting block body 10 also has a top surface 13 and a bottom surface 14 arranged oppositely, the briquetting block body 10 There are connected long perforation holes 20 and long accommodation grooves 30 inside, the long perforation holes 20 penetrate the bottom su...

Embodiment 2

[0061] Please refer to 12, which is a schematic structural diagram of the fixed pressing block 100 of the second embodiment of the present invention. The bit part, the limit part is located at the periphery of the long perforation 20. In this embodiment, the limiting portion is a limiting protrusion, further, the limiting protrusion is preferably a limiting rib 70, the number of limiting ribs 70 is two, and the two limiting ribs 70 are symmetrically arranged in the long perforation 20 sides.

[0062] When the fixed pressure block 100 is converted from the retracted state to the expanded state, the assembly part 300 with the flange 320 located in the first groove 31 is first slightly loosened by a tool, so that the flange 320 is higher than the limiting rib 70; then Use a screwdriver or other tools to move the fixed pressure block 100, so that the first end 11 of the fixed pressure block 100 protrudes out of the gap 201. When the fixed pressure block 100 moves to the limit pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com