A button threading machine with automatic feeding function

An automatic feeding and buckle threading machine technology, which is applied in the direction of buckles, fasteners, conveyor objects, etc., can solve the problems of buckle specifications that are difficult to unify, cannot meet production needs, and product consistency is poor, so as to facilitate follow-up operations , Good product consistency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

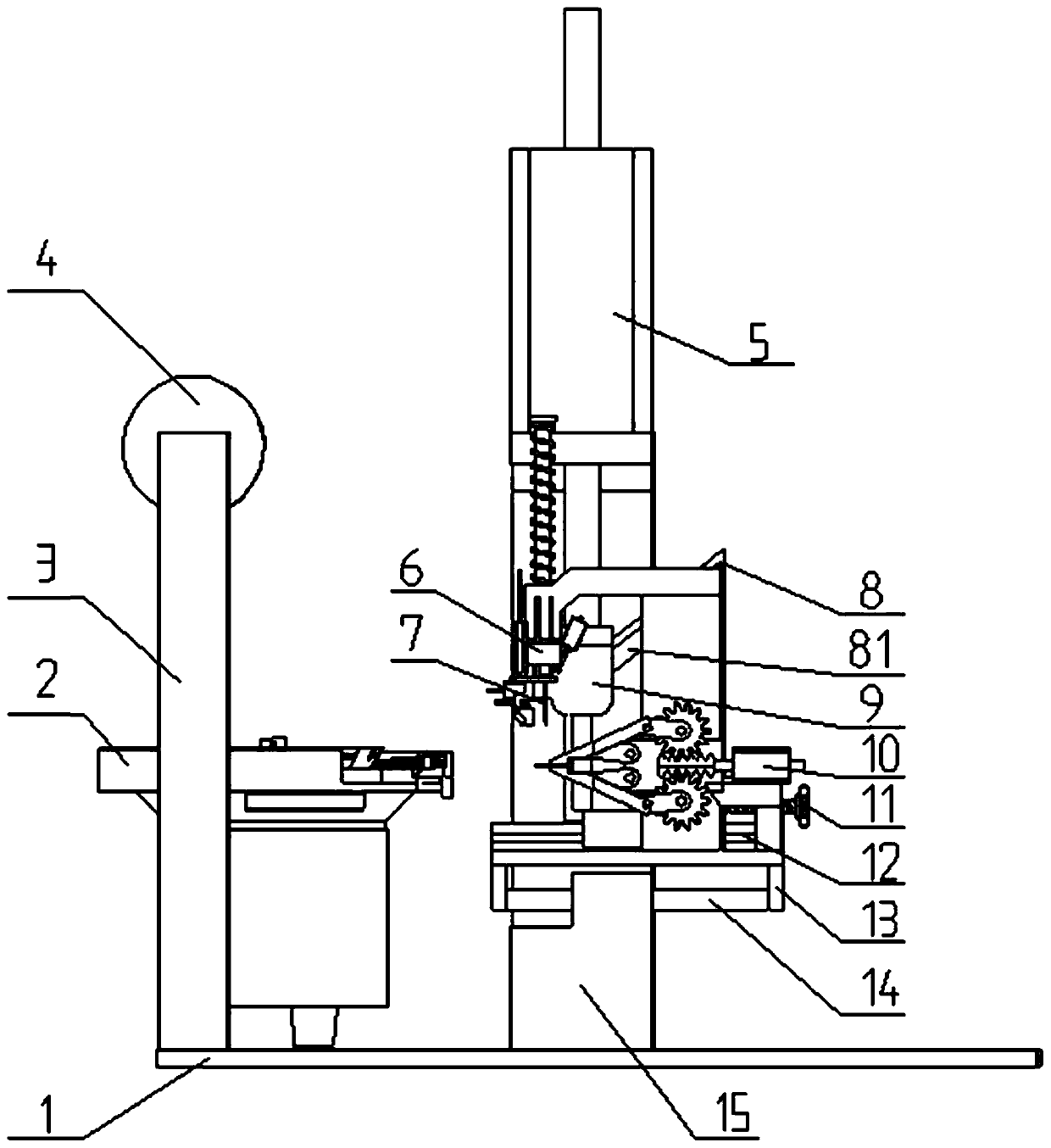

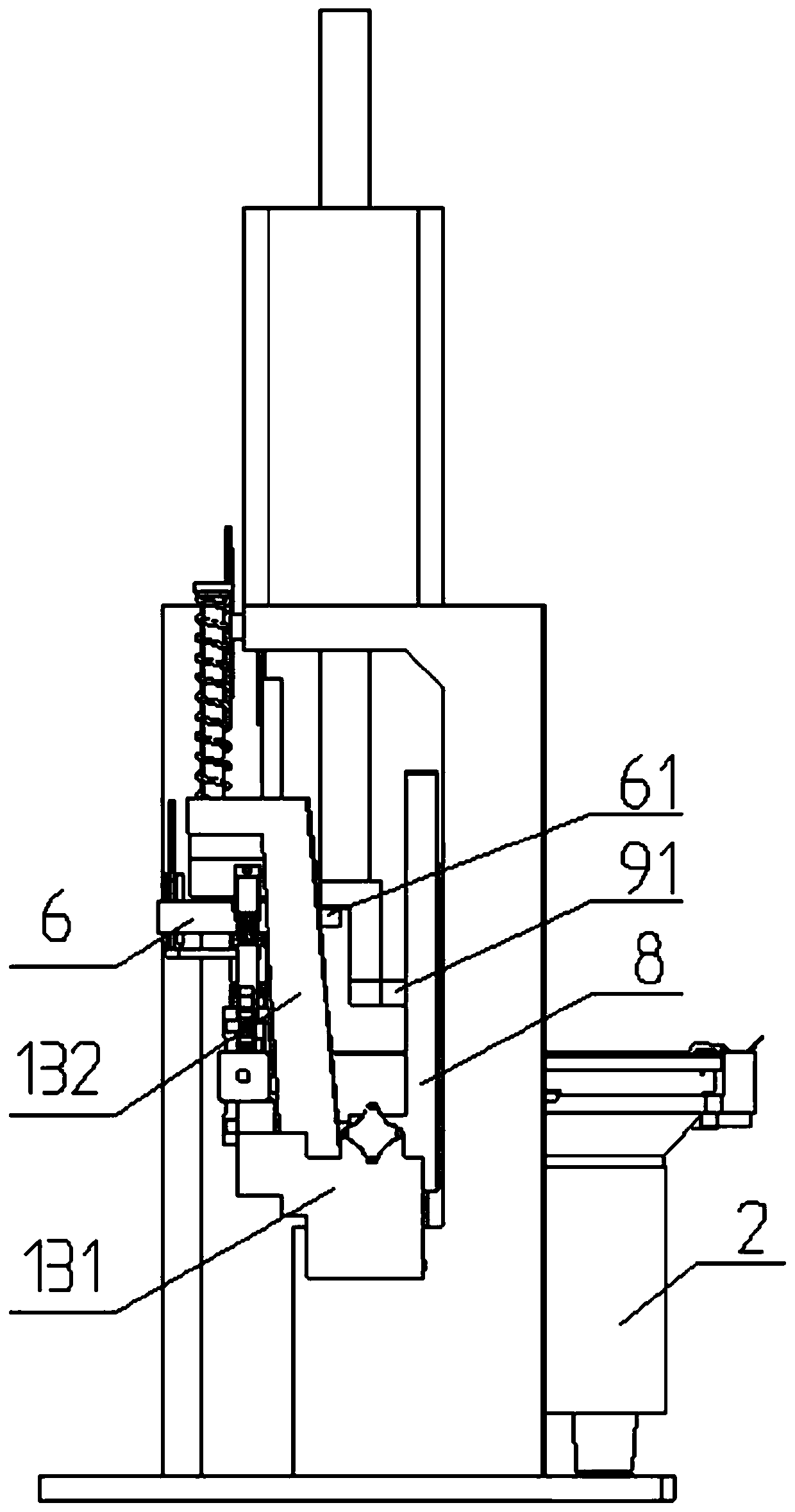

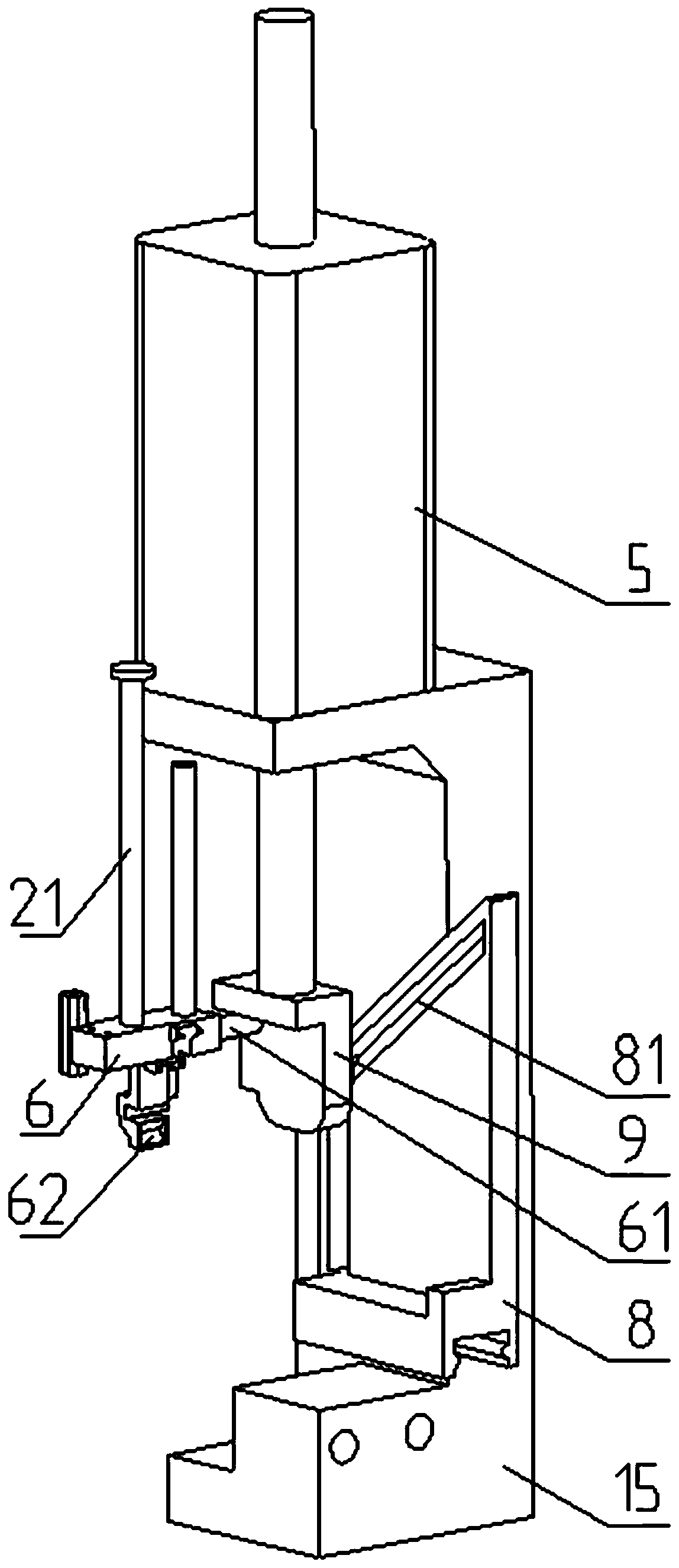

[0037] Such as Figure 1-Figure 9 As shown, the present invention relates to a buckle threading machine with automatic feeding function, which includes a machine base 1, on which a cloth belt runner 4 and a buckle feeding device 2 arranged front and back are installed near one end of the machine base 1, Cloth tape runner 4 is rotatably installed on the upper end of a vertical plate 3 and is fixed on the support 1 by vertical plate 3, is used for placing the cloth tape for use. The buckle feeding device 2 is a vibrating plate, and a baffle plate is provided at the front end of the discharge slideway of the vibrating plate, which is used to block the buckle to be taken away sent out by the vibrating plate.

[0038] An intermittent linear reciprocating mechanism is arranged at the middle part on the base 1, and a manipulator 10 is arranged on the sliding seat 13 of the intermittent linear reciprocating mechanism for realizing intermittent linear reciprocating motion to clamp the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com