Shoe sole injection mold and shoe sole processed by adopting same

A technology for injection molds and shoe soles, applied in shoe soles, applications, footwear, etc., can solve the problems of complex process and poor consistency, and achieve the effects of simple process, reduced production cost, and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

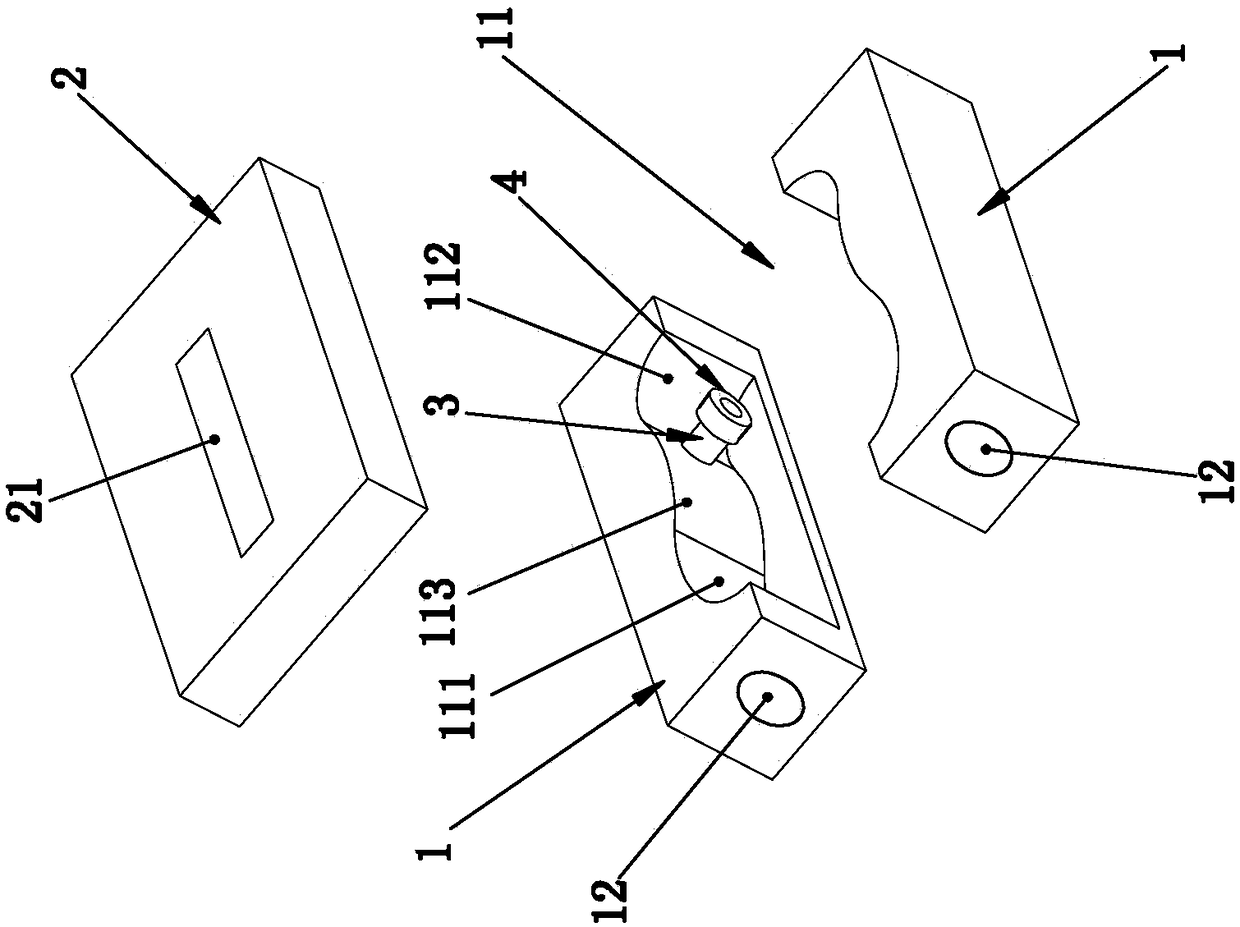

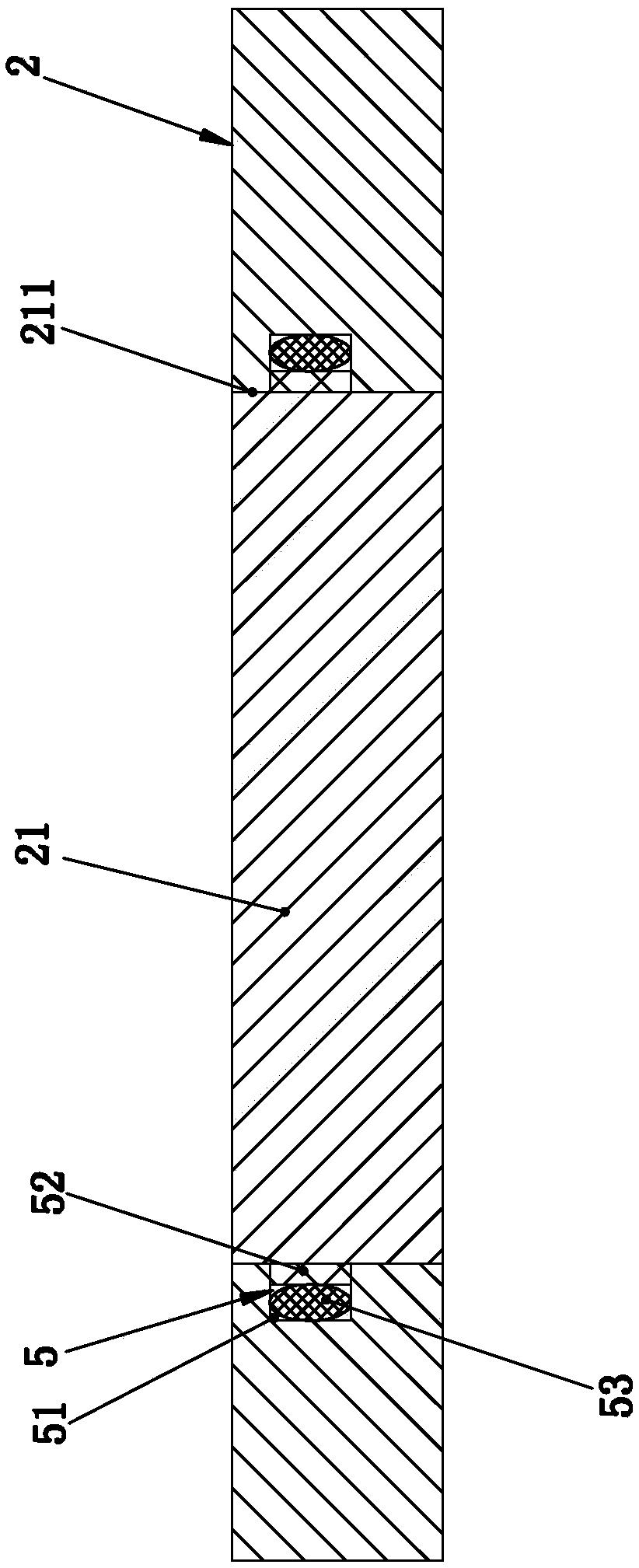

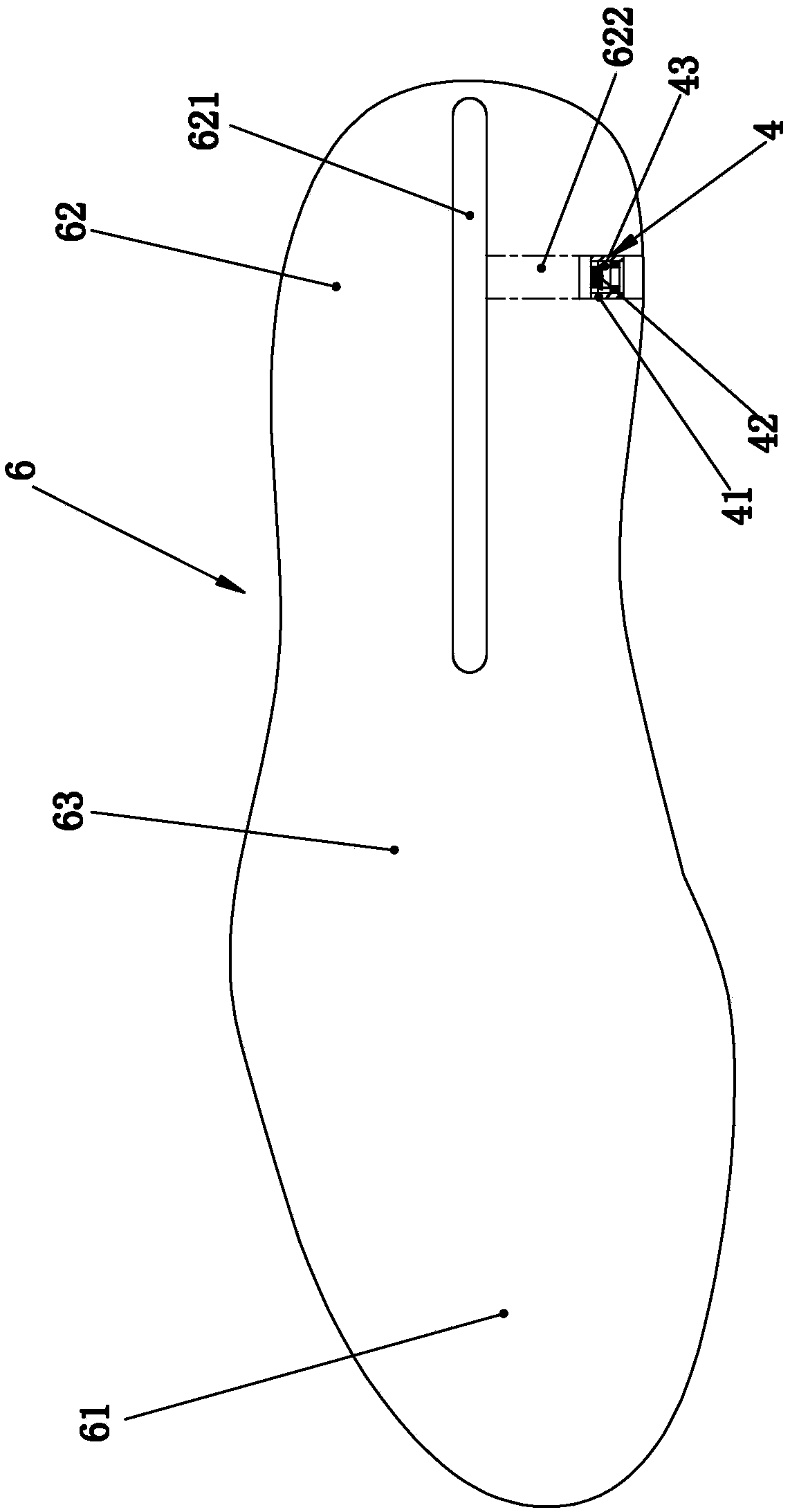

[0021] Such as figure 1 , figure 2 The shoe sole injection mold shown includes two modules 1 that can be spliced and combined or separated. There is a cavity 11 for shoe sole molding between the two modules 1. The top of the cavity 11 is equipped with a The mold cover 2, the two modules 1 are respectively provided with a heating channel 12 along its longitudinal direction, the end surface of the mold cover 2 facing the cavity 11 is provided with an exhaust channel injection block 21 that can move back and forth towards the cavity 11, and the cavity 11 Including the forefoot part 111 of the sole, the heel part 112 and the middle part 113 of the sole, the mold cavity 11 is located at any side of the heel part 112 of the sole, and is provided with a mounting hole positioning column 3 extending toward the transverse middle part of the cavity 11, and the mounting hole positioning The other end of the column 3 relative to the end connected with the cavity 11 extends to a positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com