Handling and conveying belt based on pretreatment equipment for tire pyrolysis

A pretreatment and conveying line technology, applied in the field of conveying and conveying lines, can solve the problems of long cracking time, time-consuming and labor-consuming, waste of cost, etc., and achieve the effect of improving cracking efficiency, solving time-consuming and labor-consuming, and reducing cracking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

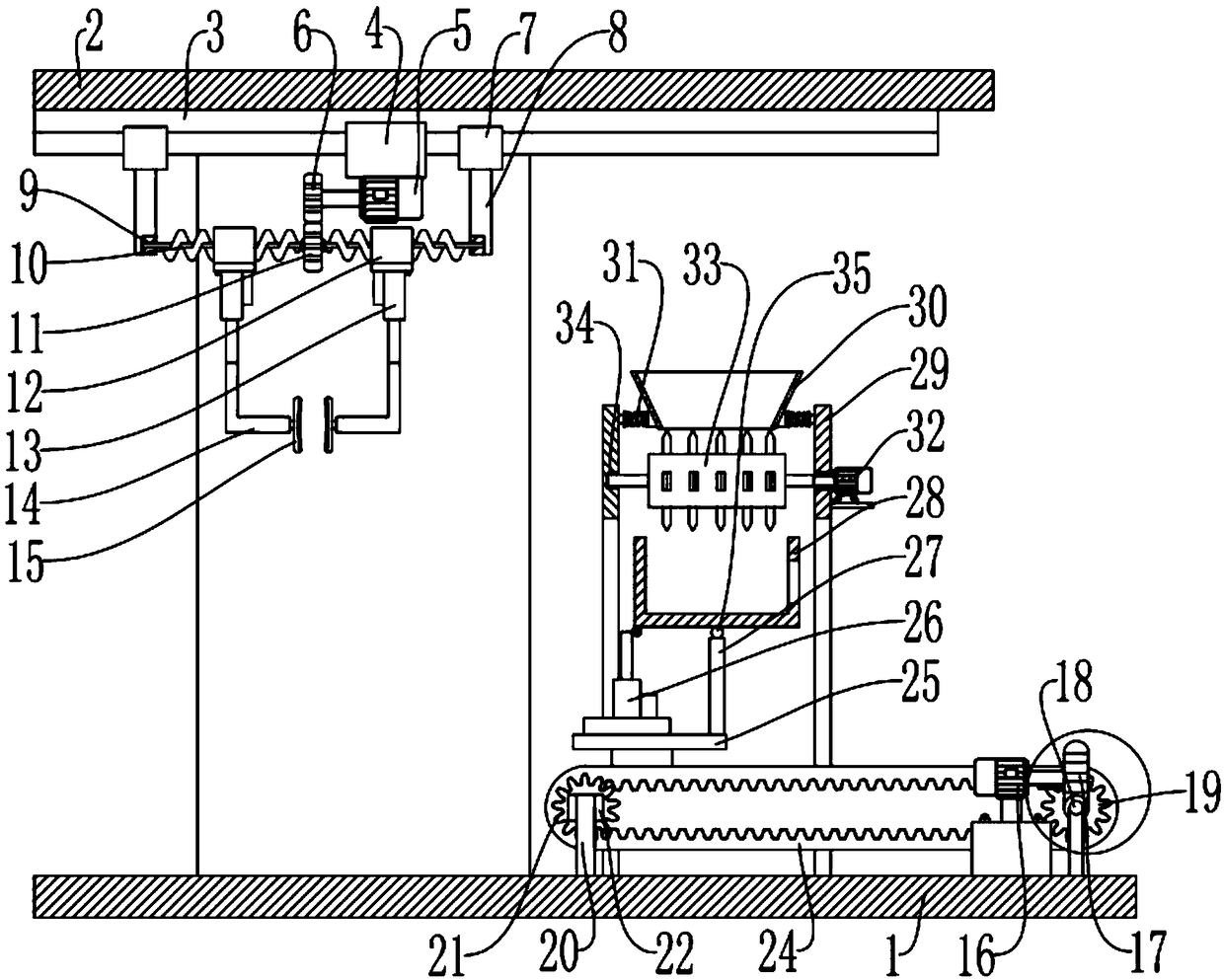

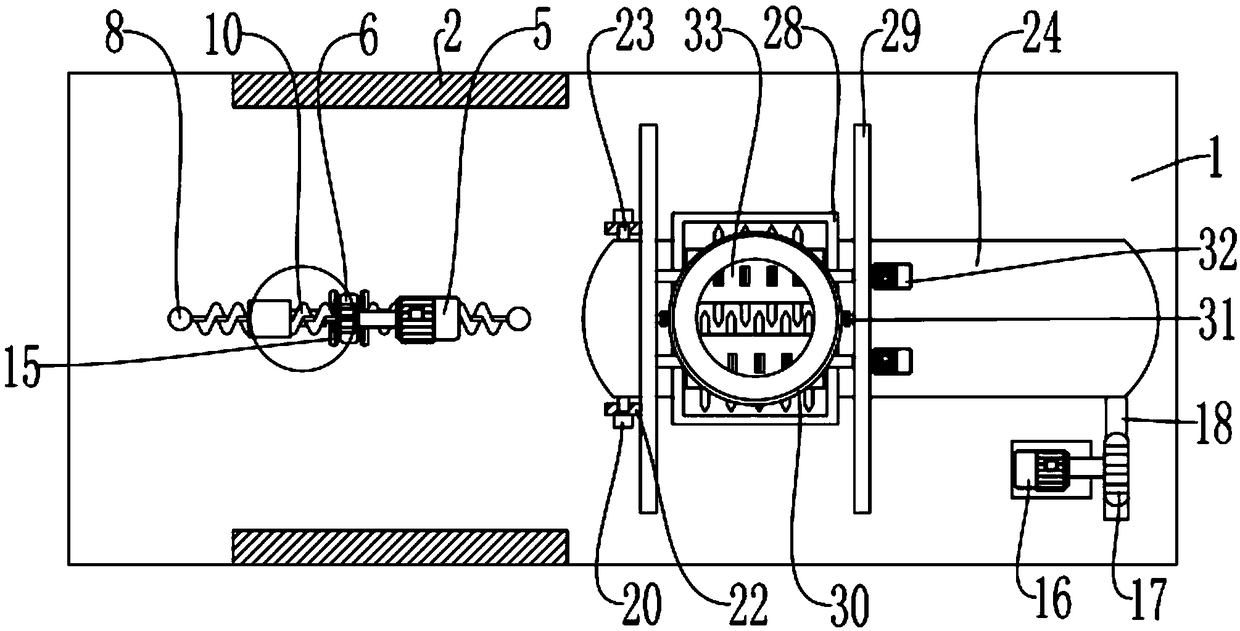

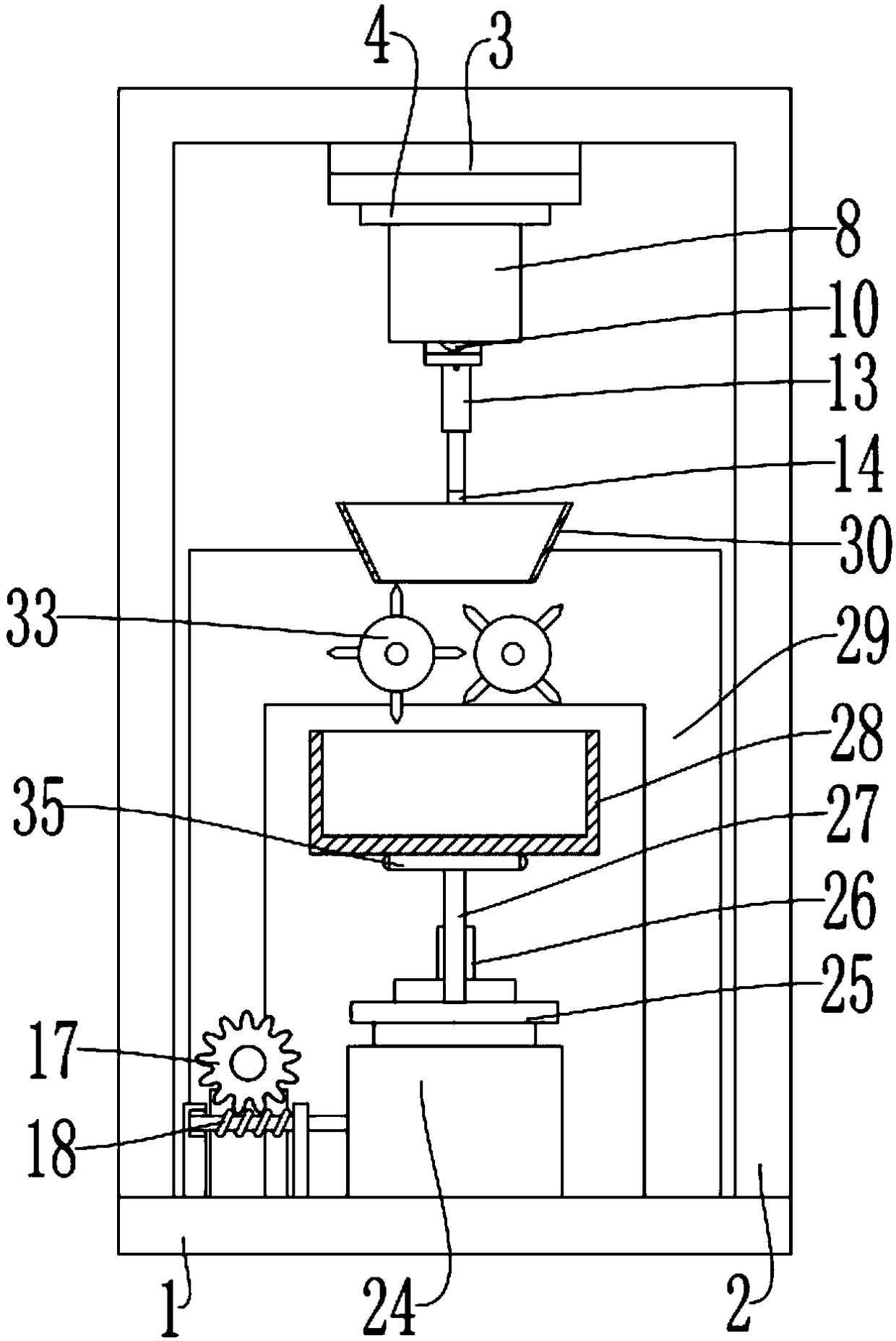

[0052] Embodiment: During the tire cracking pretreatment process, start the power supply, and the electric slide rail 3 will move left and right, driving the first servo motor 5 connected to it to move in the same direction, and when the tire is placed, the electric slide rail 3 will stop , and then the first electric push rod 13 is started, driving the fastening clip 14 connected to it to move downward in a straight line, and will stop when it touches the tire. At this time, the controller will send a signal to the motor driver, the first servo motor 5 Start, the driving end rotates clockwise, driving the driving wheel 6 to move in the same direction, and the driven wheel 11 moves in the opposite direction, driving the threaded screw 10 connected to it to rotate in the same direction. At this time, it is installed on a pair of threaded screw 10 The pair of moving seats 12 will move toward each other due to the rotation of the threaded screw 10, which realizes the clamping func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com