A software self-locking manipulator positioning method

A positioning method and manipulator technology, applied in the field of manipulators, can solve problems such as unstable grasping, poor adaptability of clay pots, and damage to clay pots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

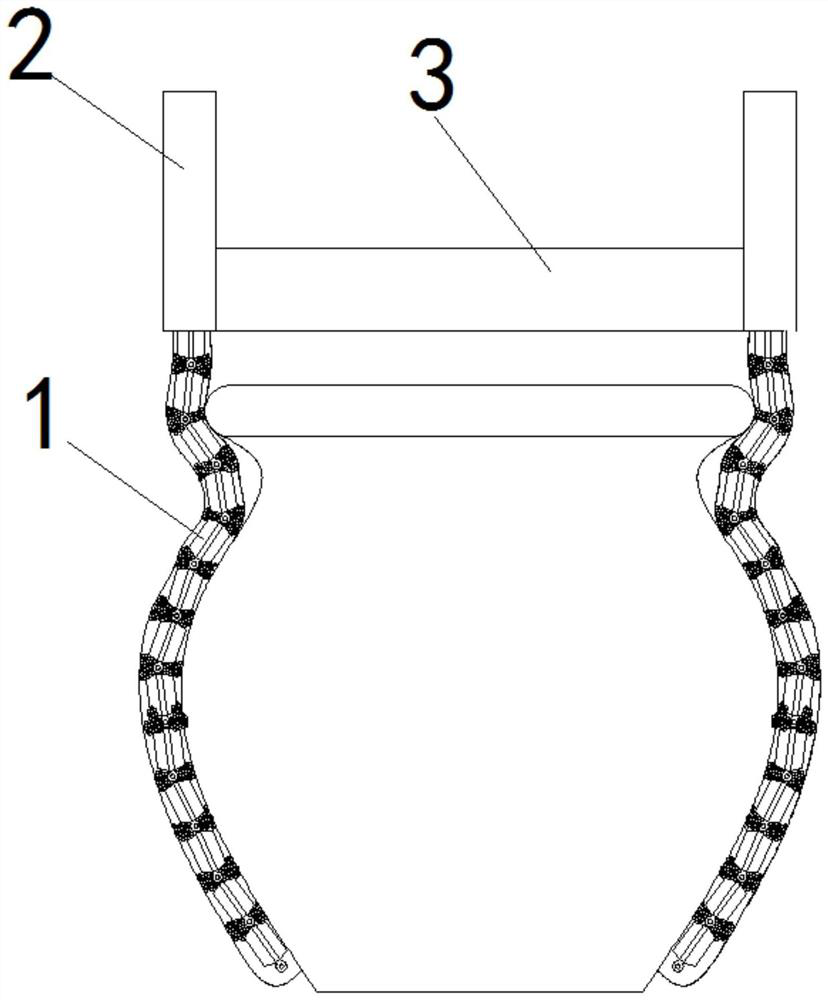

[0043] combine figure 1 As shown, a software self-locking manipulator disclosed in this embodiment includes: a manipulator joint 1, a joint accommodation bin 2, and a base 3. The base 3 is provided with several slideways, and several slideways are based on The center of the seat 3 is set as the center of the circle along the radially equally divided circle, and each of the slides is provided with a joint accommodation bin 2, and a plurality of manipulator joints 1 are arranged in the joint accommodation bin 2, and several manipulator joints 1 are hinged head to tail in sequence The connection forms a joint chain; the base 3 is used as the connection between the support and the lifting structure, and the position of the joint chain is adjusted through the joint accommodation chamber 2 on the base 3 to adapt to pottery pots of different shapes and sizes. to crawl;

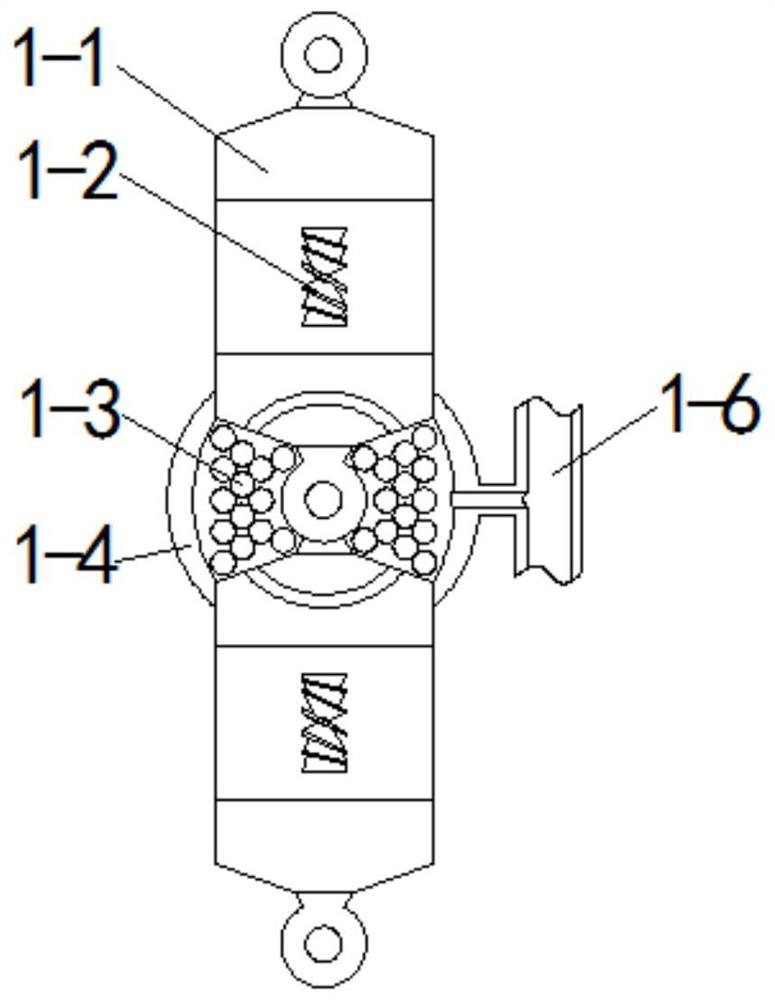

[0044] combine figure 2As shown, the manipulator joint includes: a joint body 1-1, a fitting device 1-2, a fill...

specific Embodiment approach 2

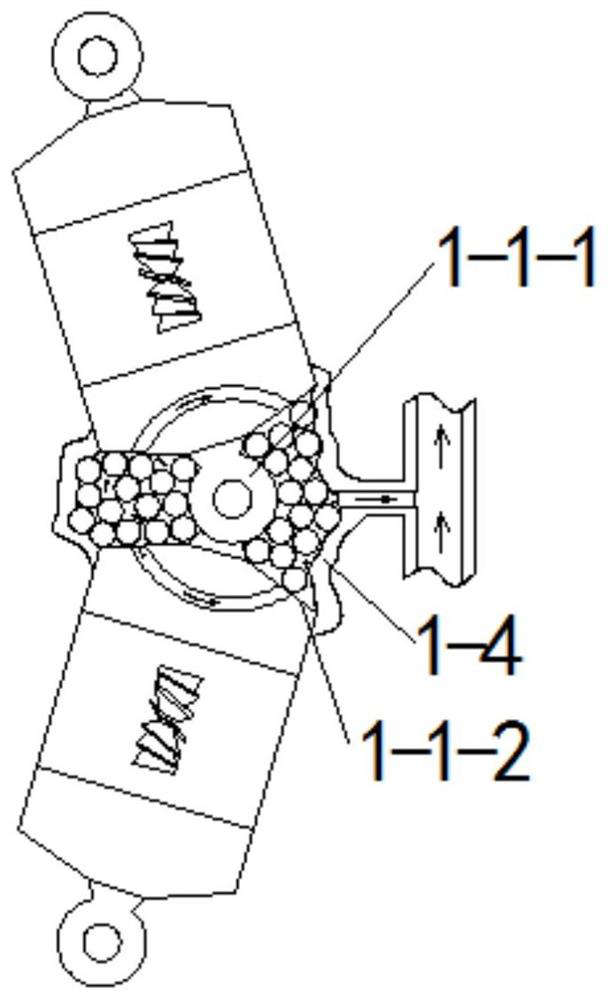

[0049] This embodiment is based on Embodiment 1. Specifically, the inner side of the cladding layer 1-4 is provided with a protruding end extending toward the hinge of the joint body 1-1. -4 when the filler 1-3 is squeezed, the protruding end pushes the filler 1-3 toward the pressure surfaces 1-1-2 on both sides.

specific Embodiment approach 3

[0050] This embodiment is based on the specific implementation mode 1 or 2. Specifically, the fillers 1-3 are several spherical fillers, and the spherical fillers are provided with through holes for ventilation. The cladding layer 1 The inner side of -4 is provided with a separation layer, the separation layer is a mesh structure, the spherical filling is arranged in the separation layer, and the separation layer covers the filling 1-3 without affecting the air flow. When the vacuum is drawn, the filler 1-3 is moved out of the cavity along with the cladding layer 1-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com