Manipulator pottery pot grabbing method

A technology for manipulators and pottery pots, applied in the field of manipulators, can solve the problems of unstable grasping, easy deformation, and inability to complete the grasping of pottery pots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

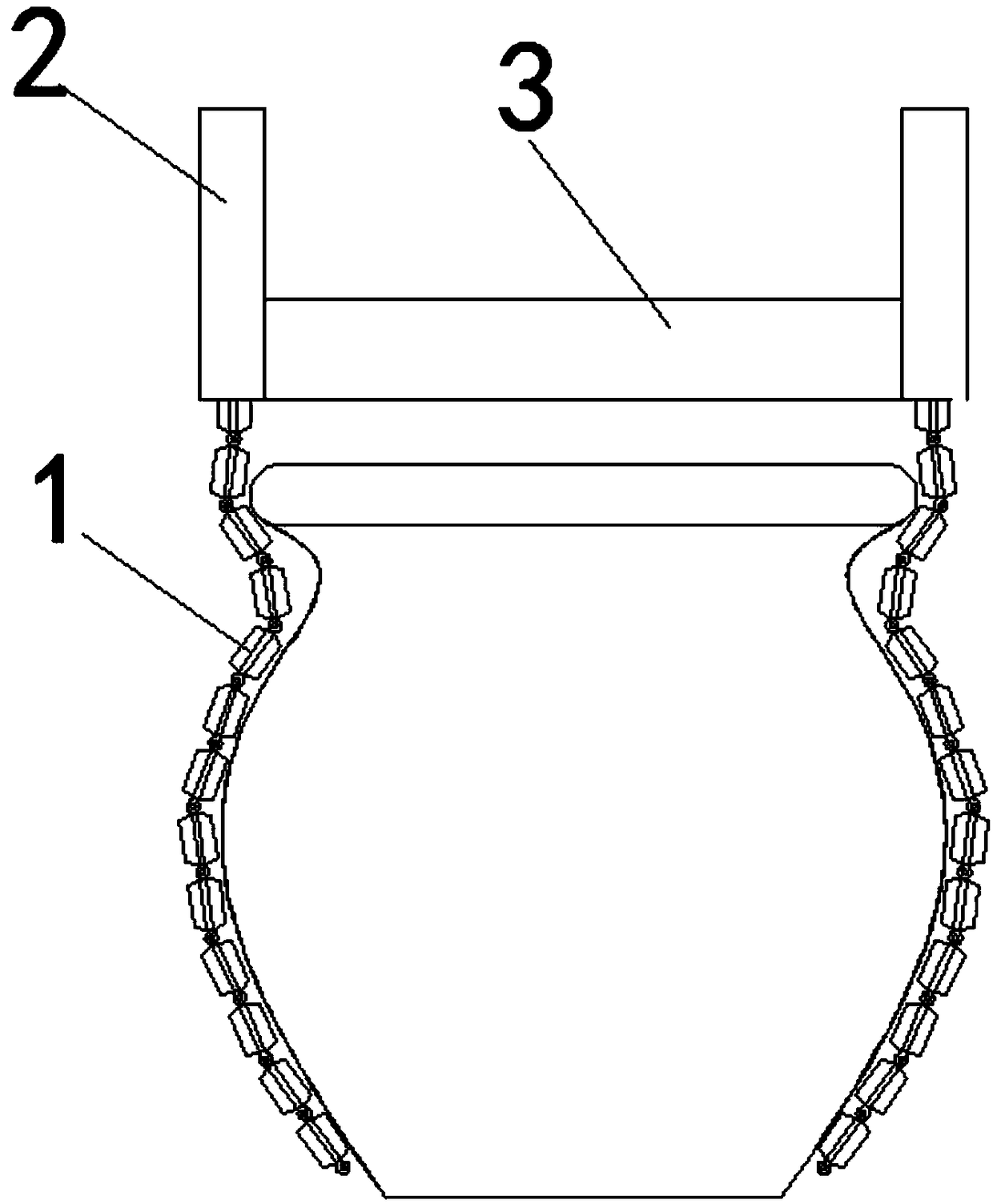

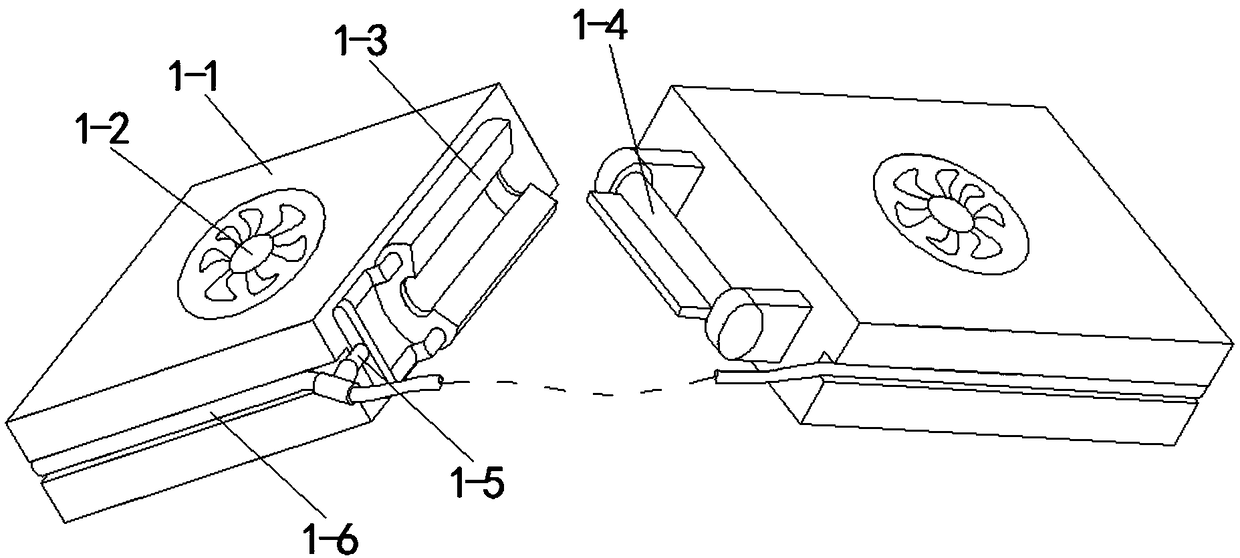

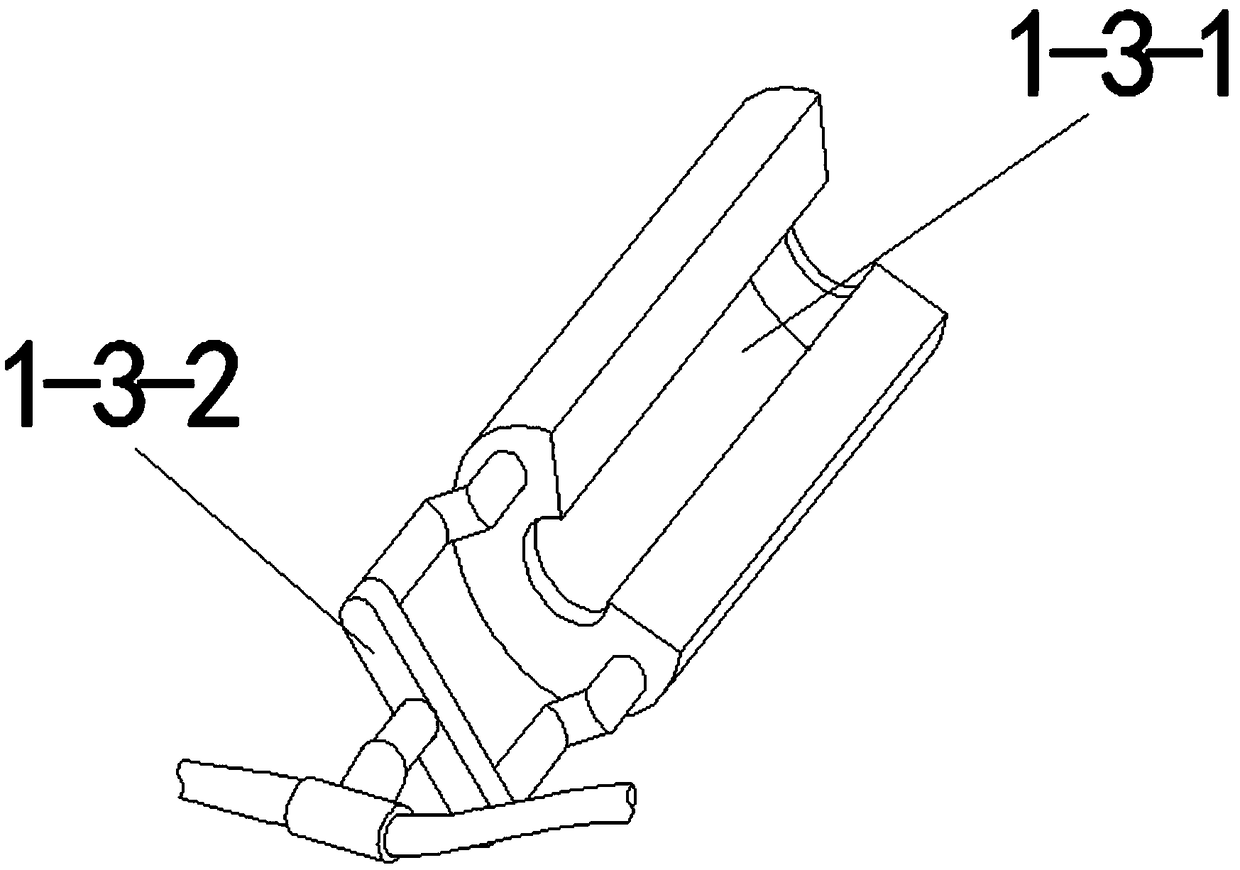

[0042] combine figure 1As shown, an adaptive grasping manipulator disclosed in this embodiment includes: a manipulator joint 1, a joint accommodation bin 2, and a base 3. The base 3 is provided with several slideways, and several slideways are used to The center of the base 3 is set as the center of the circle along the radially equally divided circle, and each slideway is provided with a joint accommodation bin 2, and a plurality of manipulator joints 1 are arranged in the joint accommodation bin 2, and several manipulator joints 1 are arranged in sequence from end to end The hinged connection forms a joint chain; the position of the joint chain is adjusted by moving the joint storage compartment 2, the joint chain slides out from the joint storage compartment 2, and slides along the side wall of the clay pot from top to bottom, and the joint chain fits the clay pot After the side wall forms a curve that fits the clay pot, and then fixes the shape of the joint chain to realiz...

specific Embodiment approach 2

[0049] This embodiment is based on Embodiment 1. Specifically, the upper end of the joint storage bin 2 is provided with a reel, which is driven by a reel motor, and a rope is arranged on the reel, and one end of the rope is wound on the reel On the drum, the other end of the rope is connected to the uppermost manipulator joint 1 of the joint chain, and is used to pull the manipulator joint 1 to slide in the joint accommodation bin 2. By controlling the speed of the reel motor, the speed of the joint chain sliding down is controlled. After the joint chain slides to the bottom end of the joint storage compartment 2, the uppermost joint 1 of the manipulator is stuck at the opening of the joint storage compartment 2. After the grabbing is completed, the joint chain is pulled by the reel and returned to the joint storage compartment. 2 within.

specific Embodiment approach 3

[0050] This embodiment is based on the specific implementation mode 1. Specifically, the laminating device 1-2 is an electromagnet, and the electromagnet is powered by an external wire. The attractive force of the body makes the joint 1 of the manipulator close to the surface of the tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com