Manipulator joint

A technology of manipulators and grasping manipulators, which is applied in the field of manipulators, and can solve the problems of fragile pots, easy deformation, and different external curves of pots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

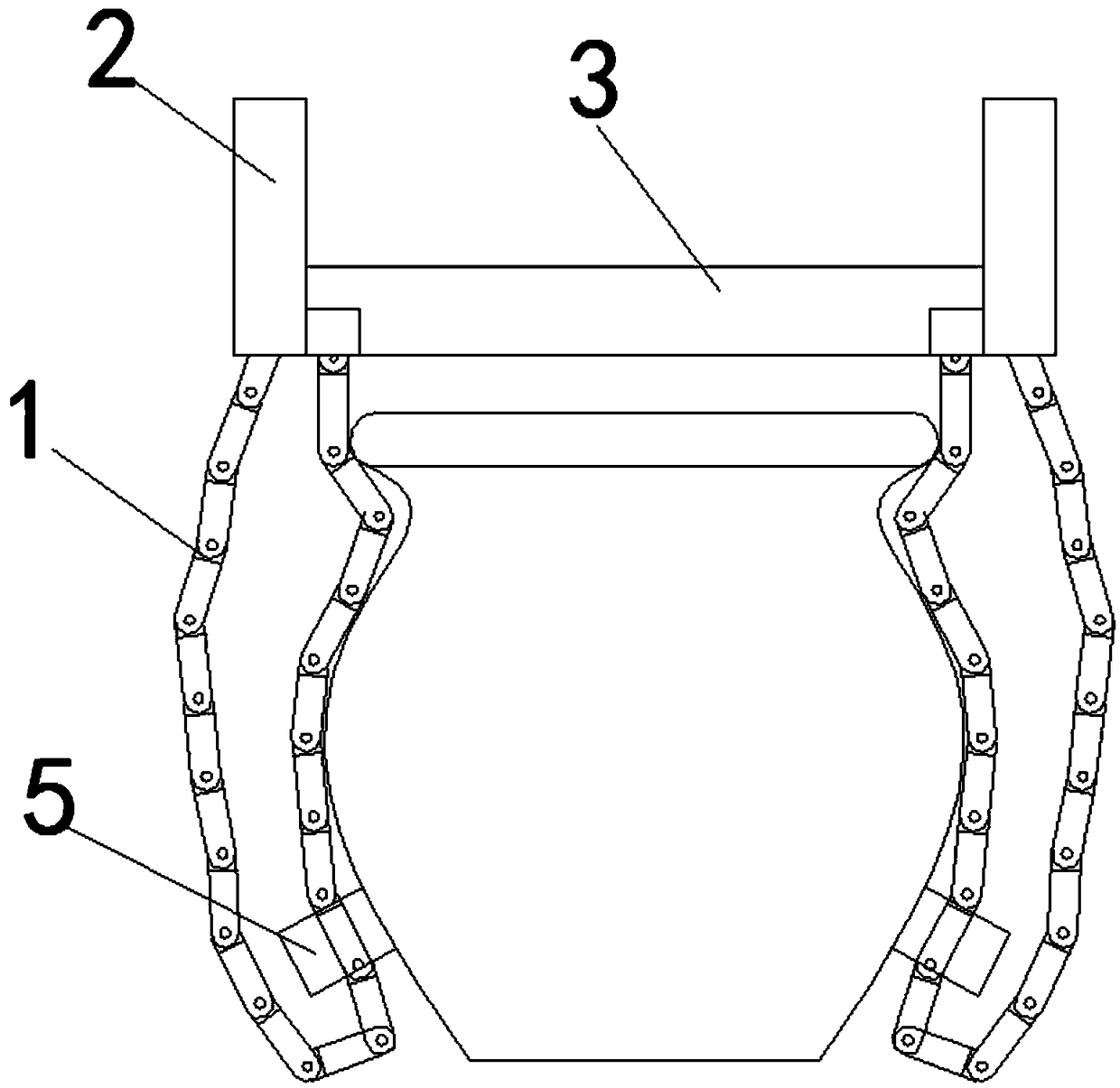

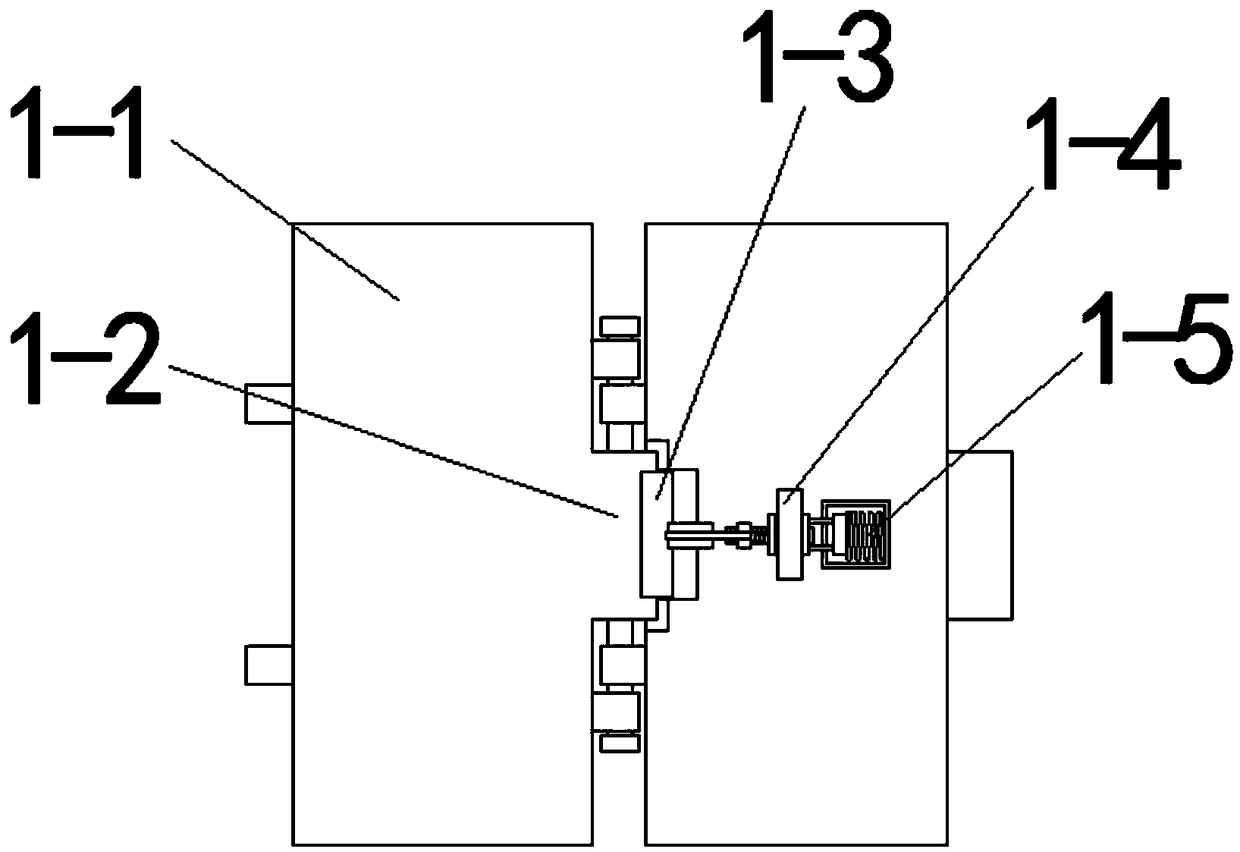

[0040] An adaptive intelligent grasping manipulator disclosed in this embodiment, combined with figure 1 As shown, specifically, it includes: a manipulator joint 1, a joint accommodation bin 2, a base 3 and a tracking vehicle 5, the base 3 is provided with several slideways, and several slideways are centered on the base 3 The center of the circle is arranged to equally divide the circumference in the radial direction, and each slideway is provided with a joint accommodation bin 2, and a plurality of manipulator joints 1 are arranged in the joint accommodation bin 2, and several manipulator joints 1 are hingedly connected from head to tail to form a joint chain , one end of the articulated chain is accommodated in the joint storage compartment 2, the other end of the articulated chain is fixed at the opening of the joint storage compartment 2, and the joint chain is provided with a tracking vehicle 5; the base 3 is used as a whole support structure, and the base 3 Connect with...

specific Embodiment approach 2

[0044] This embodiment is based on the specific implementation mode 1, specifically, in combination with Figure 6 As shown, the outside of the articulated chain is covered with a rubber layer 6 .

specific Embodiment approach 3

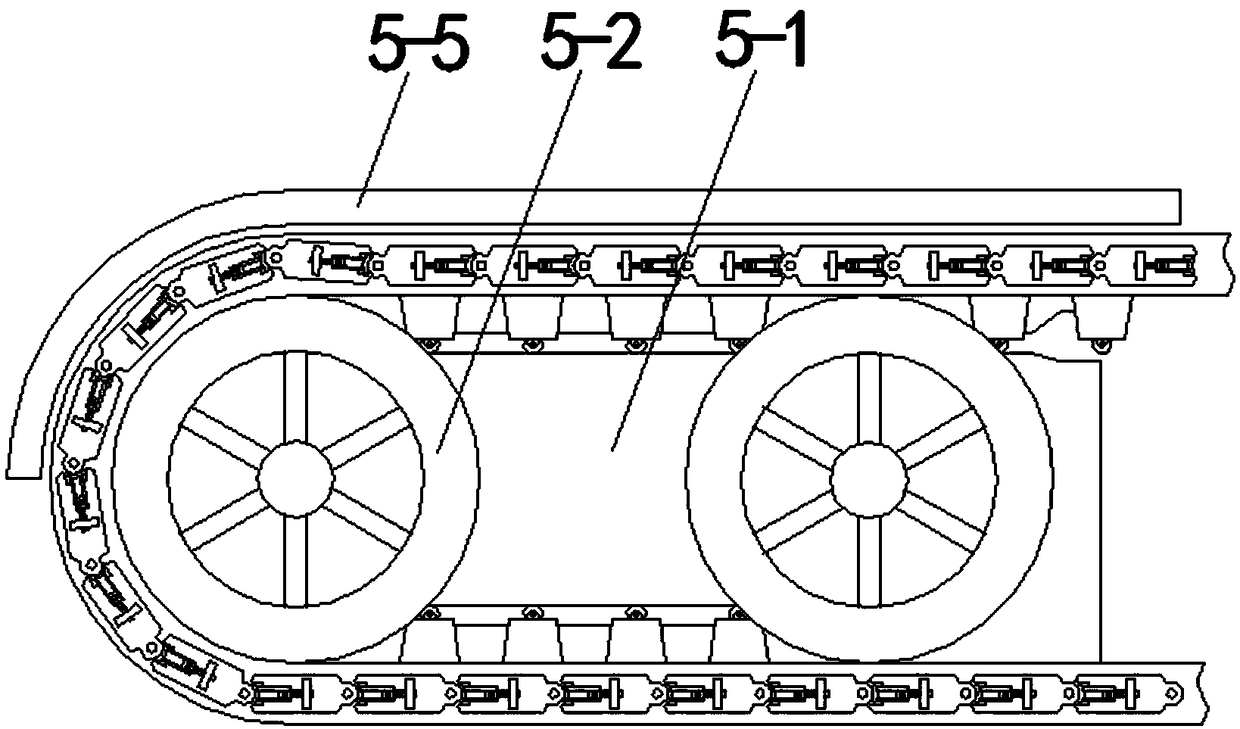

[0045] This embodiment is based on the second specific implementation mode, specifically, in combination with Figure 6 As shown, two groups of fixed block groups are arranged in parallel on one side of the rubber layer 6, and each group of fixed block groups includes several fixed blocks 6-1 arranged at intervals, and a fixed shaft body 6-2 is arranged on the upper end of the fixed block, The side of the car body 5-1 is provided with a shaft body chute 6-3, and the shaft body chute 6-3 goes around two wheels 5-2 shafts from the upper side of one end of the car body 5-1 and returns to The lower side of the starting end forms a U-shaped chute, the fixed shaft body 6-2 is embedded in the shaft body chute 6-3; the fixed shaft body 6-2 on the fixed block 6-1 is embedded in the shaft body chute 6-3 is used for the positioning of the articulated chain and the car body, while making the sliding of the tracking car 5 stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com