Full-automatic installation device and method for safety air bag plastic part

An airbag and installation device technology, applied in the field of vehicles, can solve the problems of complex assembly process, difficult quality assurance, rising labor costs, etc., and achieve the effects of compact and reasonable layout, convenient management, and reduced labor input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

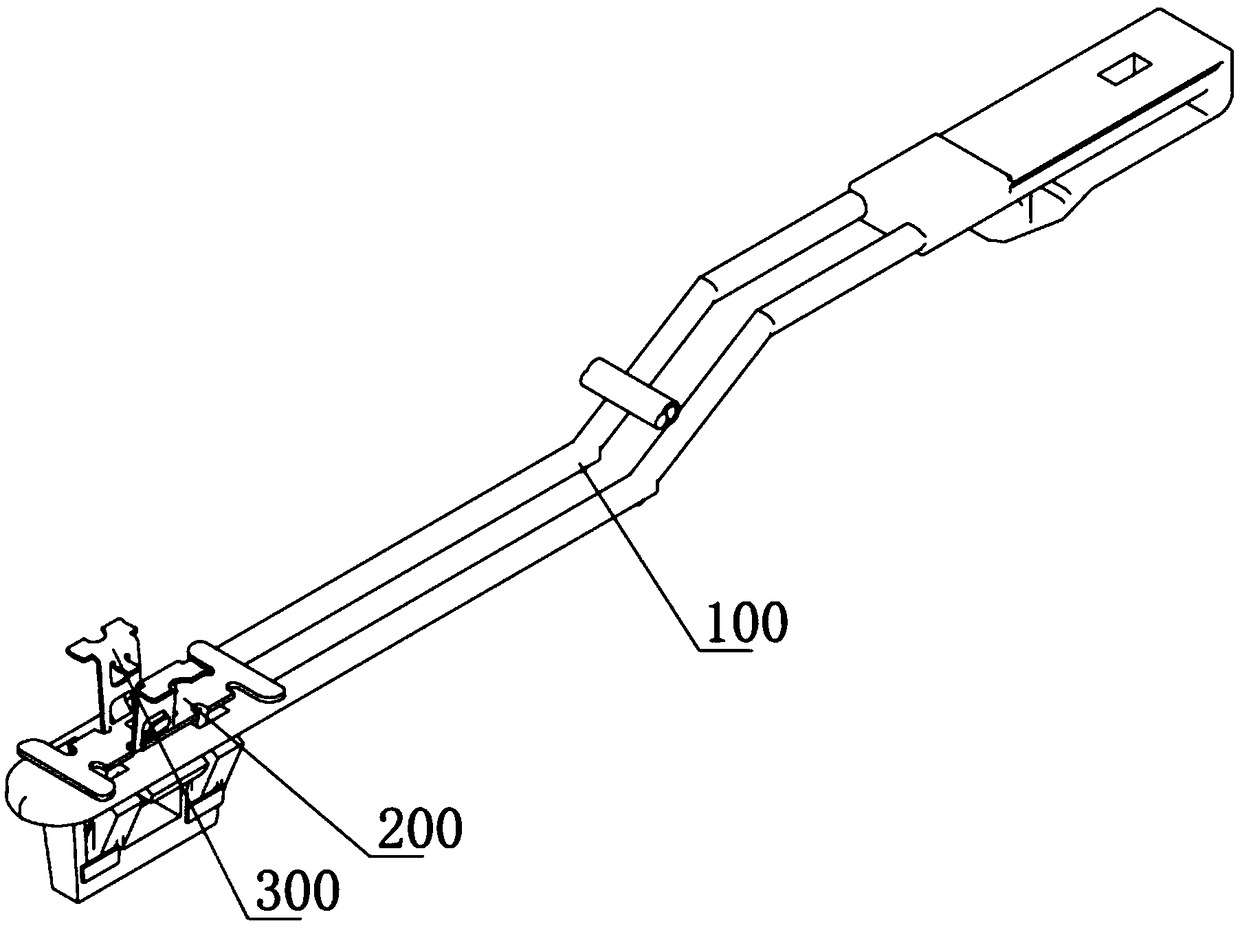

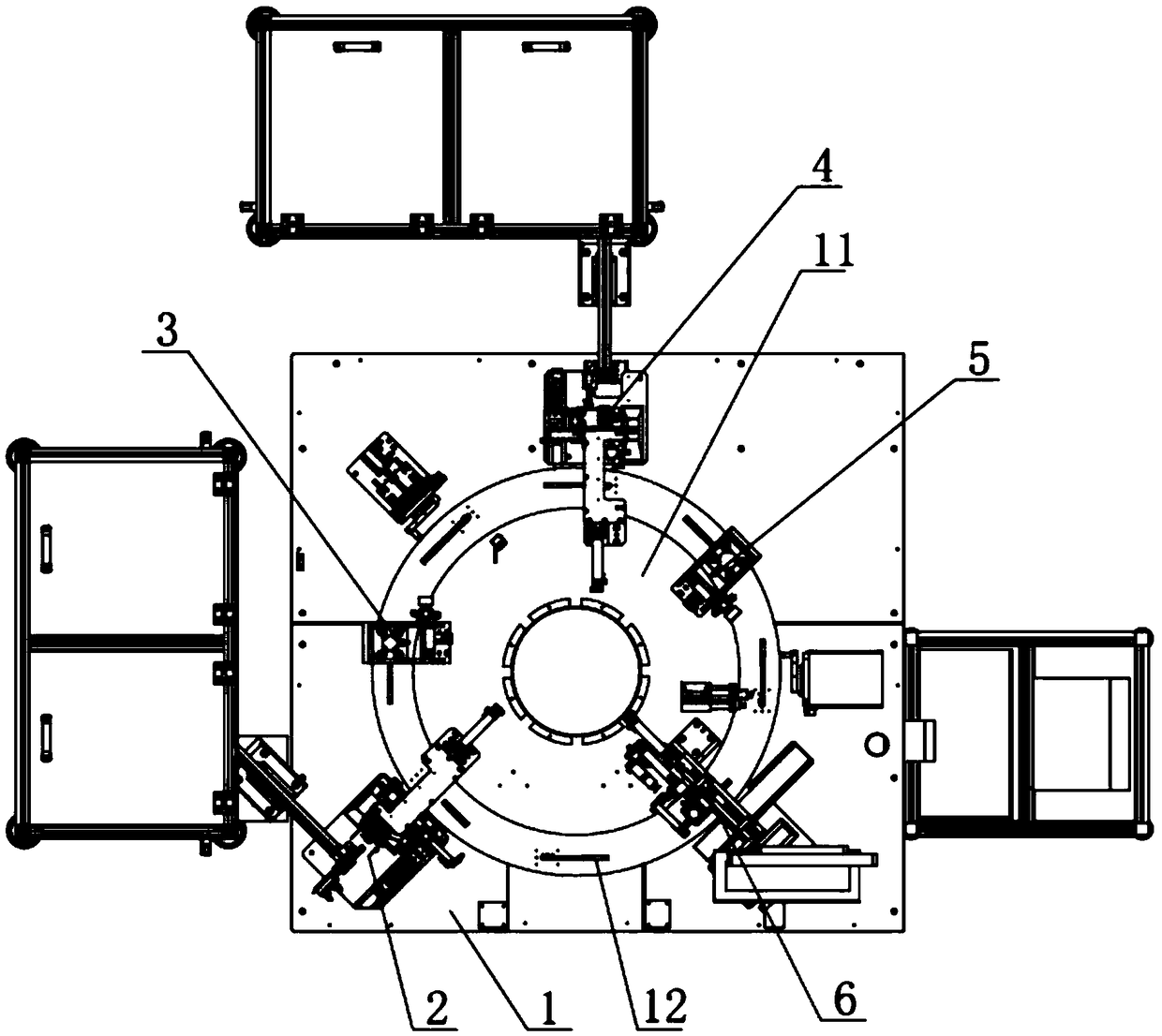

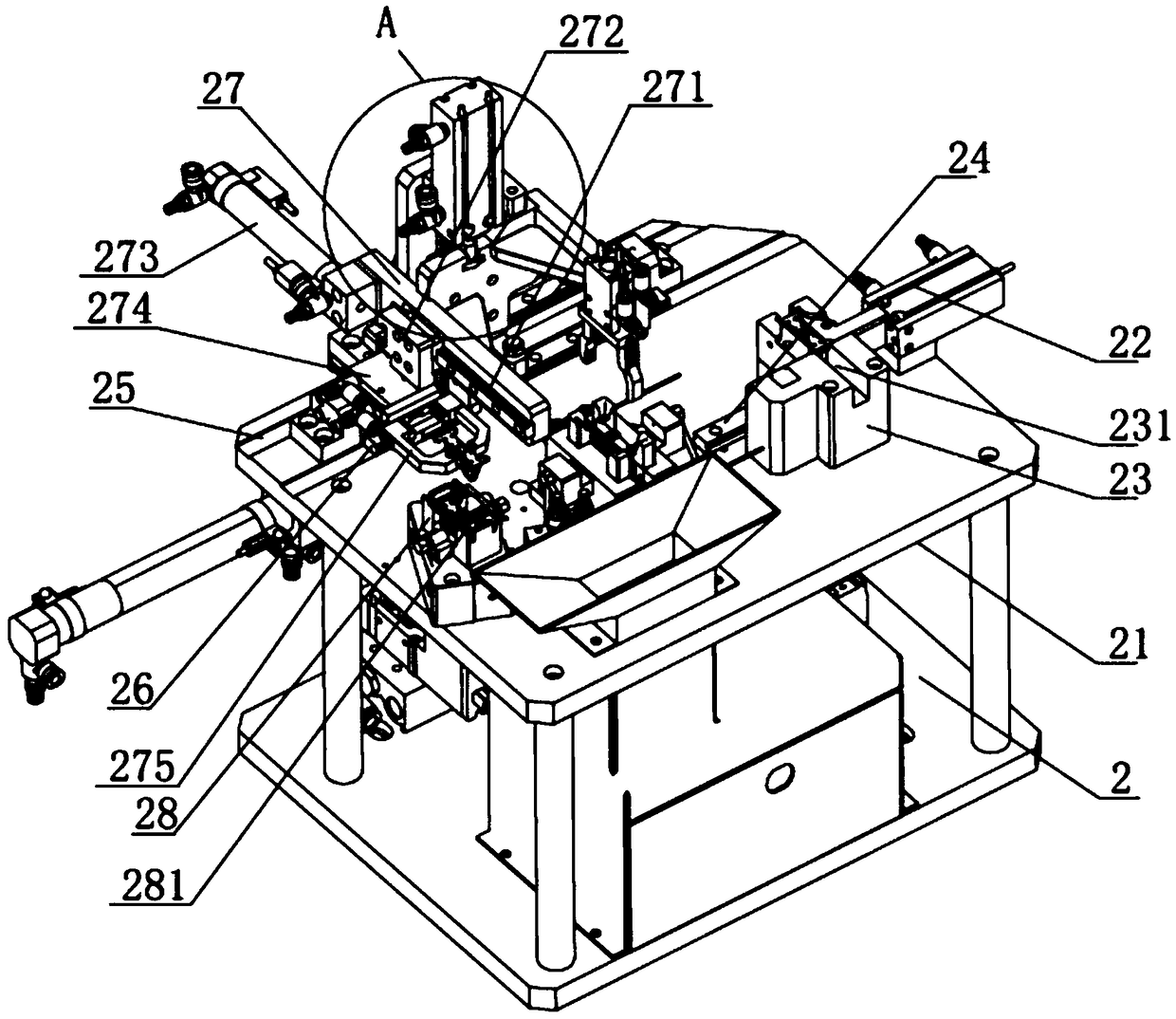

[0035] like Figure 1 to Figure 9 As shown, the present invention discloses a fully automatic installation device for plastic parts of an airbag, which includes a frame 1 and a turntable 11 arranged on the frame 1 which can rotate by itself. The turntable 11 is provided with a set of plastic bodies 100 And the bearing seats 12 arranged equidistantly. Along the rotation direction of the turntable 11, the frame 1 is sequentially provided with a clamping component 2 for grabbing the clamping component 200 and clamping it on the plastic body 100 and a clamping component 2 for clamping the clamping c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com