Efficient automatic overturning and lifting tool

A technology of flipping, lifting and tooling, which is applied to auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems that the height and size of corrugated boards cannot be adjusted flexibly, and manual handling is laborious and laborious, so as to save manpower, improve safety, and structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

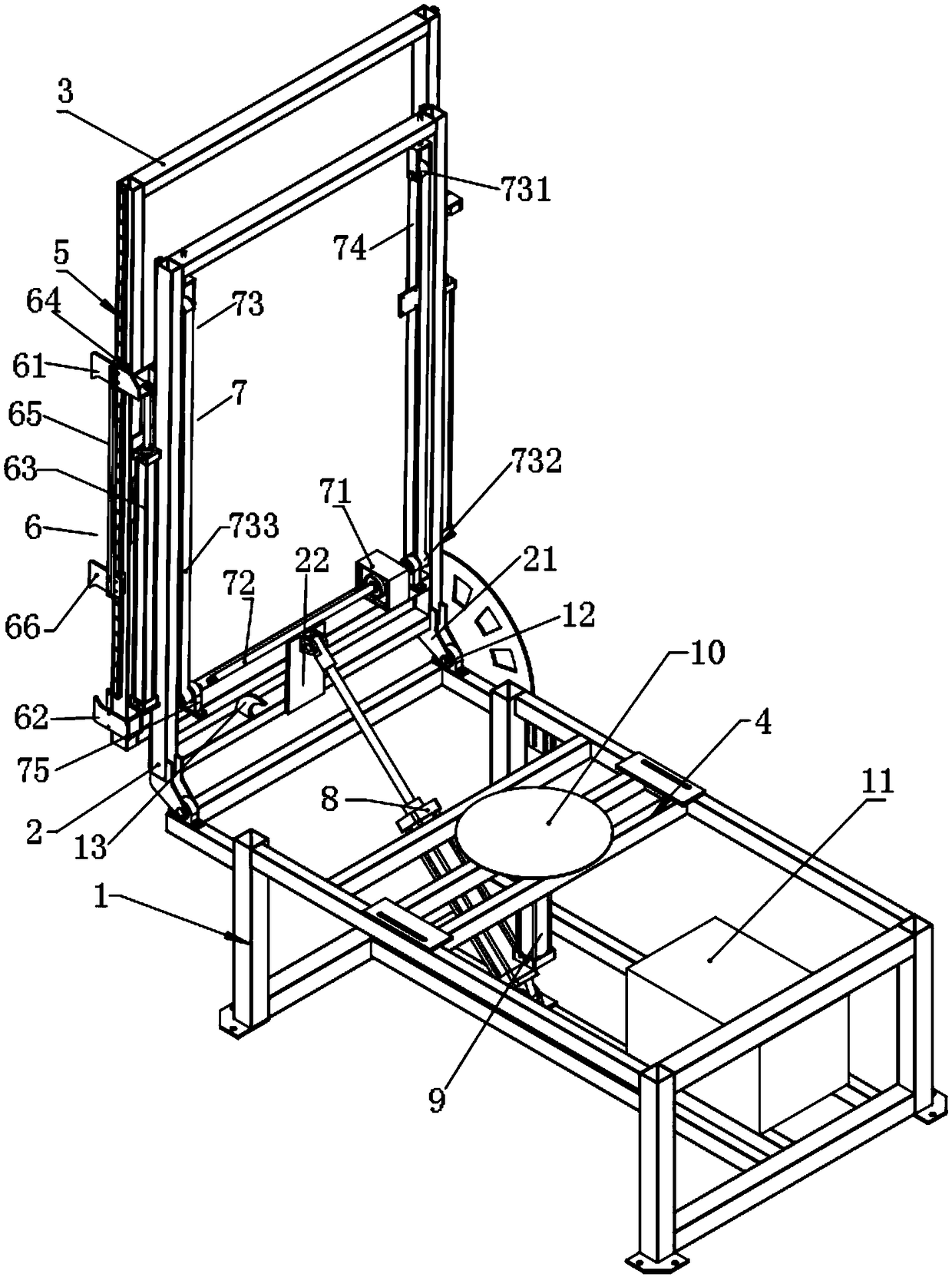

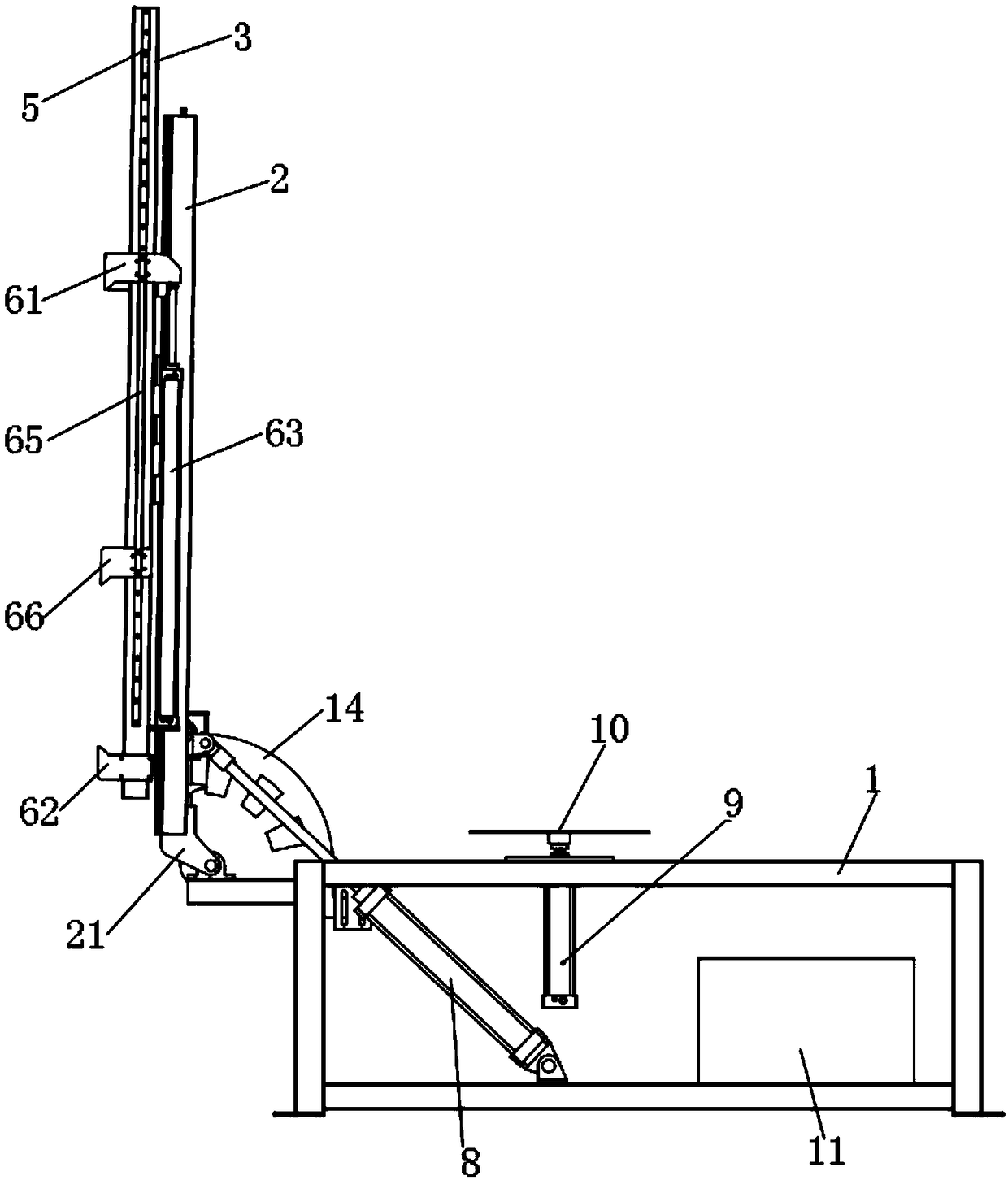

[0024] Such as Figure 1-3The high-efficiency automatic turning and lifting tooling shown includes the tooling base 1, the turning bracket 2, the lifting bracket 3, the jacking bracket 4, the linear guide rail 5, the clamping mechanism 6, the lifting mechanism 7, the turning cylinder 8, the jacking cylinder 9 and the top Lift the turntable 10, the jacking bracket 4 is arranged on the tooling base 1, the jacking cylinder 9 is arranged on the jacking bracket 4, and the jacking cylinder 9 is connected with the jacking turntable 10, one end of the turning bracket 2 Hinged with one end of the tooling base 1, the lifting mechanism 7 is arranged on the flip bracket 2, the lifting bracket 3 is arranged on the lifting mechanism 7, the linear guide rail 5 is arranged on the lifting bracket 3, and the linear guide rail 5 is located on the lifting bracket 2 On the two parallel sides of the bracket 3, the clamping mechanism 6 is arranged on the lifting bracket 3, and the clamping mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com